Cement clinker sintering technological process and device

A technology of cement clinker and process flow, applied in the field of cement clinker, to achieve the effect of maintaining temperature and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

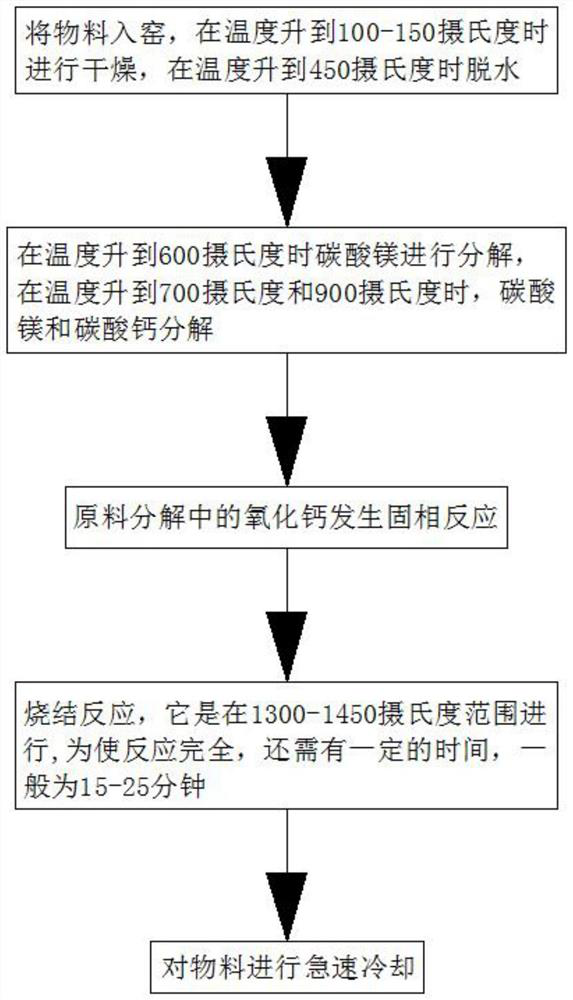

[0036] see figure 1 , a cement clinker firing process, comprising the following process:

[0037] Step 1: Put the material into the kiln, dry it when the temperature rises to 100-150 degrees Celsius, and dehydrate when the temperature rises to 450 degrees Celsius: when the temperature of the material entering the kiln rises to 100-150 degrees Celsius, all the free water in the raw material Excluded, especially in wet production, the water content in the slurry is 32-40%, this process is more important, while the moisture content of raw meal in dry production generally does not exceed 1.0%;

[0038] When the temperature of the material entering the kiln rises to 450°C, kaolin, the main component of the clay, undergoes a dehydration reaction to remove the chemically bound water. This process is an endothermic process: Al2O3·2SiO2·2H2O==Al2O3+2SiO2+2H2O dehydration After becoming amorphous trialuminum trioxide and silicon dioxide, these amorphous substances have higher activity;...

Embodiment 2

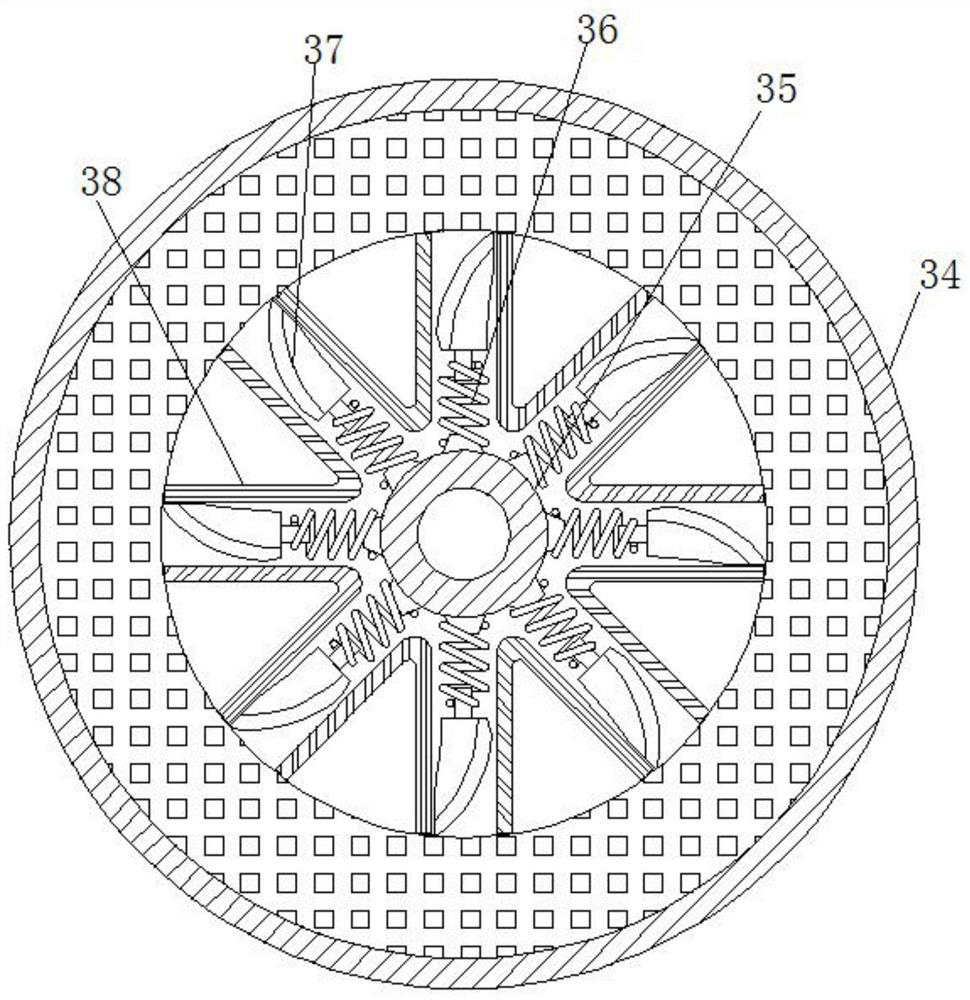

[0048] see Figure 2-4 , a cement clinker burning device, comprising a kiln 1, the top of the kiln 1 is fixedly installed with a feed port 2, the bottom of the feed port 2 is fixedly connected with a stirring tank 3, and the inside of the kiln 1 is fixedly installed with a heating tank 4 and refrigeration tank 5. The inside of the stirring tank 3 is rotatably connected with a stirring rod 31, the bottom of the stirring tank 3 is fixedly equipped with a filter port 32, the right end of the stirring rod 31 is fixedly connected with a collecting tank 33, and the bottom of the collecting tank 33 is fixedly equipped with a cutting groove 34, the cutting groove The center of 34 is rotatably connected with a rotating shaft 35, and the periphery of the rotating shaft 35 is fixedly connected with a tension spring 36, and the end of the tension spring 36 away from the rotating shaft 35 is fixedly equipped with a cutting knife 37, and the periphery of the rotating shaft 35 is fixedly con...

Embodiment 3

[0050] see Figure 1-4 , a cement clinker firing process, comprising the following process:

[0051] Step 1: Put the material into the kiln, dry it when the temperature rises to 100-150 degrees Celsius, and dehydrate when the temperature rises to 450 degrees Celsius: when the temperature of the material entering the kiln rises to 100-150 degrees Celsius, all the free water in the raw material Excluded, especially in wet production, the water content in the slurry is 32-40%, this process is more important, while the moisture content of raw meal in dry production generally does not exceed 1.0%;

[0052] When the temperature of the material entering the kiln rises to 450°C, kaolin, the main component of the clay, undergoes a dehydration reaction to remove the chemically bound water. This process is an endothermic process: Al2O3·2SiO2·2H2O==Al2O3+2SiO2+2H2O dehydration After becoming amorphous trialuminum trioxide and silicon dioxide, these amorphous substances have higher activi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com