High-quality low-oxygen copper rod and preparation method thereof

A low-oxygen copper, high-quality technology, applied in the direction of cable/conductor manufacturing, process efficiency improvement, root rod/rod/wire/strip conductor, etc., can solve the problem that the copper rod cannot be connected stably and effectively, and affects the normal use of the copper rod , poor performance of copper rods, etc., to achieve the effect of increased connection surface, improved stability, and improved recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

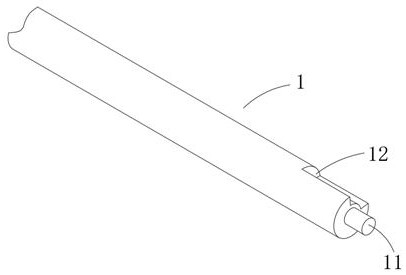

[0031] like figure 1 As shown, a high-quality low-oxygen copper rod proposed by the present invention includes a copper rod body 1, a connecting groove 11 is provided on the central axis of one end of the copper rod body 1, and a connecting column 12 is provided at one end of the copper rod body 1; 12 is a quarter arc groove; the diameter of the copper rod body 1 is 8mm, and the diameter of the connecting column 12 is 3mm.

[0032] In this embodiment, a method for preparing a high-quality low-oxygen copper rod is also proposed, comprising the following steps:

[0033] Step 1: raw material processing;

[0034] Selection of raw materials: Raw materials include 20 parts of first-class scrap copper with copper content above 99.8%, 15 parts of second-class scrap copper with copper content of 98.8%-99.8%, 65 parts of third-class scrap copper with copper content of 95%-98.8% share;

[0035] Feeding and melting: Add the selected raw materials into the reverberatory furnace, heat up...

Embodiment 2

[0045] like figure 1 As shown, a high-quality low-oxygen copper rod proposed by the present invention, compared with Embodiment 1, this embodiment also includes a copper rod body 1, a connecting groove 11 is provided on the central axis of one end of the copper rod body 1, and the copper rod body One end of 1 is provided with a connecting column 12; the connecting column 12 is a quarter arc groove; the diameter of the copper rod body 1 is 8mm, and the diameter of the connecting column 12 is 3mm.

[0046] In this embodiment, a method for preparing a high-quality low-oxygen copper rod is also proposed, comprising the following steps:

[0047] Step 1: raw material processing;

[0048] Selection of raw materials: raw materials include 30 parts of first-class scrap copper with copper content above 99.8%, 20 parts of second-class scrap copper with copper content of 98.8%-99.8%, and 50 parts of third-class scrap copper with copper content of 95%-98.8% share;

[0049]Feeding and me...

Embodiment 3

[0059] like figure 1 As shown, a high-quality low-oxygen copper rod proposed by the present invention, compared with Embodiment 1 or Embodiment 2, this embodiment also includes a copper rod body 1, and the central axis of one end of the copper rod body 1 is provided with a connecting groove 11 One end of the copper rod body 1 is provided with a connecting column 12; the connecting column 12 is a quarter circular groove; the diameter of the copper rod body 1 is 8mm, and the diameter of the connecting column 12 is 3mm.

[0060] In this embodiment, a method for preparing a high-quality low-oxygen copper rod is also proposed, comprising the following steps:

[0061] Step 1: raw material processing;

[0062] Selection of raw materials: raw materials include 40 parts of first-class scrap copper with copper content above 99.8%, 25 parts of second-class scrap copper with copper content of 98.8%-99.8%, 35 parts of third-class scrap copper with copper content of 95%-98.8% share;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com