Single film packaging machine

A packaging machine and single-film technology, applied in packaging, transport packaging, transportation and packaging, etc., can solve the problems of lower production efficiency, low cost of single film, and prolong working hours, so as to reduce waste of resources, reduce labor time, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

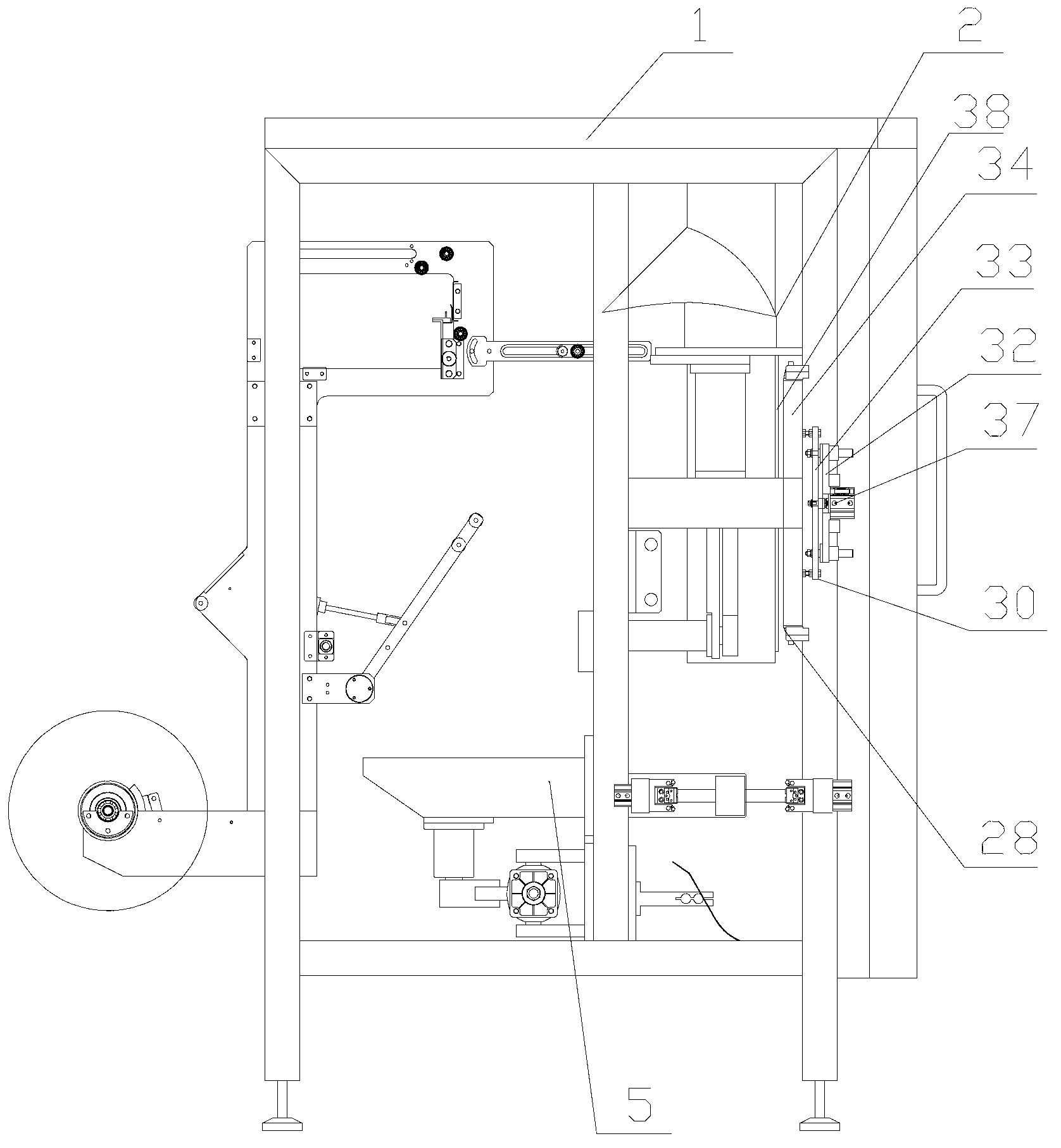

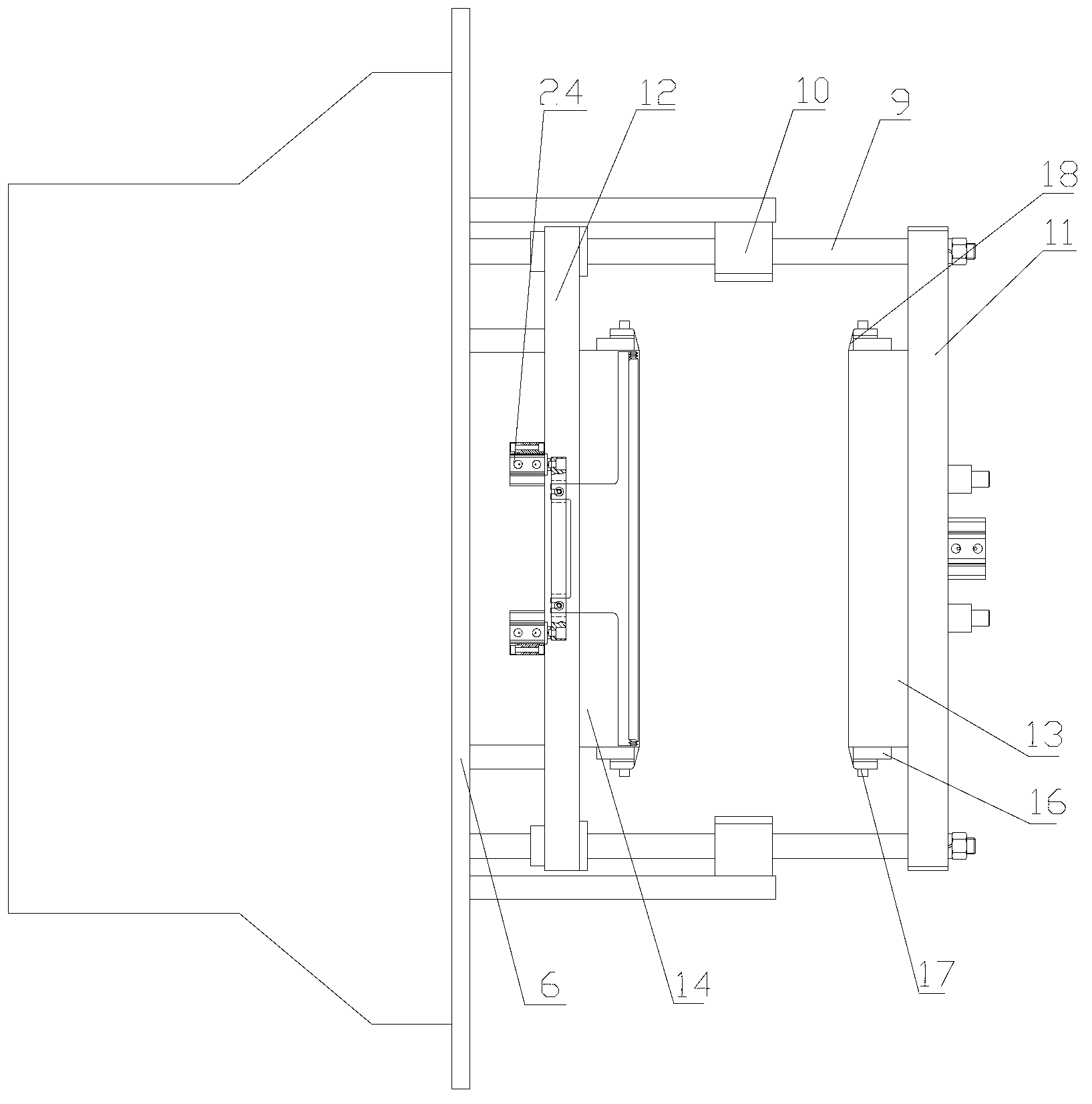

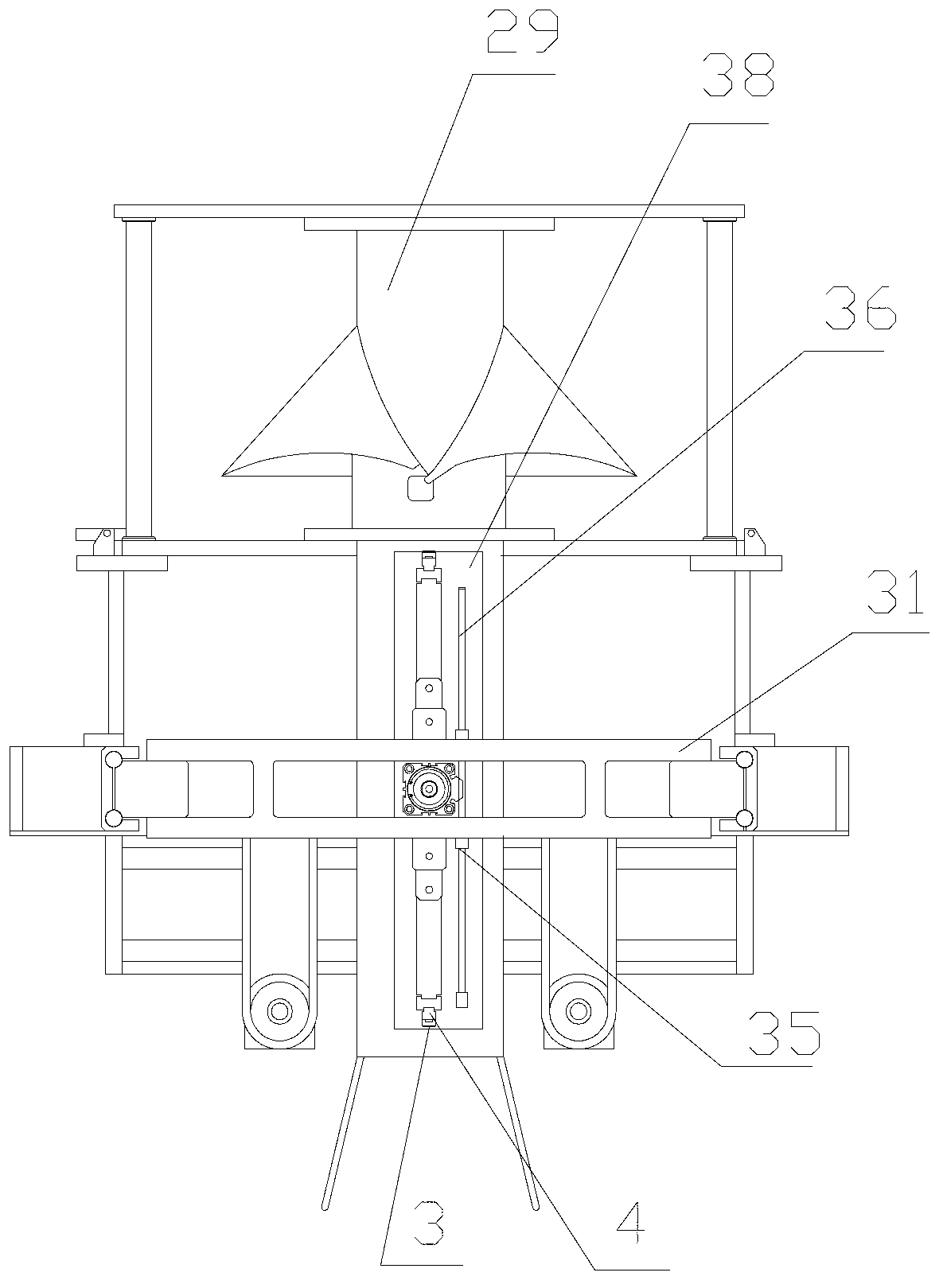

[0017] Referring to the figure, a single-film packaging machine includes a frame, and a lapel former is arranged in the frame, and a horizontal sealing mechanism is arranged below the lapel former. The lapel former includes an intermediate cylinder arranged on the frame, and the frame There is a vertical sealing mechanism on the side of the lapel former, and a temperature control system is installed on both the horizontal sealing mechanism and the vertical sealing mechanism. The inner side is provided with a middle plate, and the inner side of the middle plate is provided with a longitudinal sealing block through bolts, and one side of the longitudinal sealing block is provided with a cooling pipe fixing seat, a cooling pipe is arranged on the cooling pipe fixing seat, and a longitudinal sealing cylinder is arranged on the outer side of the cylinder block. And the longitudinal sealing cylinder passes through the beam, and the outer side of the intermediate cylinder is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com