Method for exploiting thickened oil by steam solvent mixed injection

A solvent and steam technology, applied in the fields of mining fluid, earthwork drilling, special data processing applications, etc., can solve the problems of long capital recovery time, low solvent recovery rate, weak profitability, etc., to promote solvent recovery and save steam consumption , accelerated development and oil drainage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

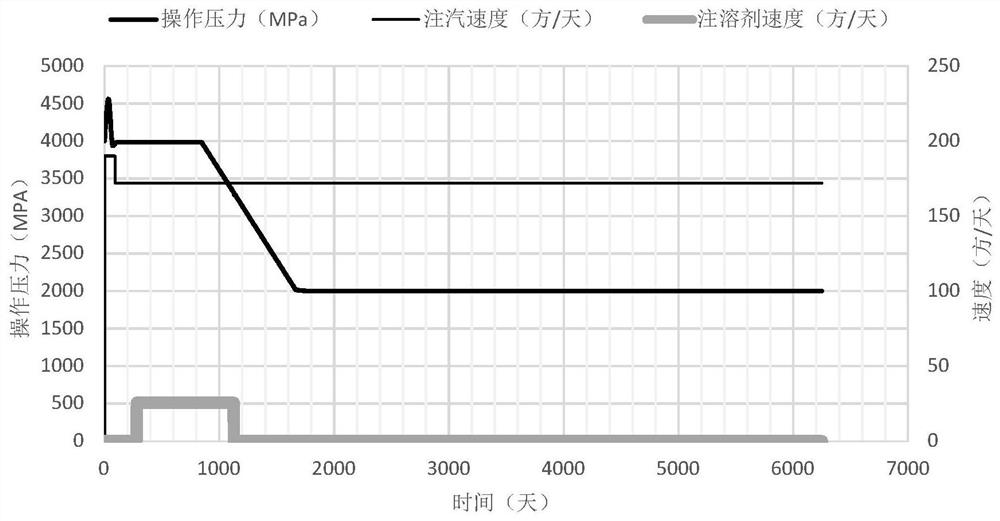

[0065] In this example, steam-solvent mixed injection is used for the following heavy oil reservoirs

[0066] The heavy oil reservoir has a burial depth of 440 meters, a degassed crude oil viscosity of 106,000 mPa s at 50 °C, a porosity of 30%, a permeability of 1.4 Darcy, an oil saturation of 90%, a reservoir thickness of 25 m, and a single well group controlled reserve of 25×100 × 400 × 0.3 × 0.85 = 255,000 tons of original oil reserves,

[0067] The shale content of this heavy oil reservoir is 1.5%. No natural fractures or gas caps have been found in well logging interpretation, and a muddy caprock with a continuous thickness greater than 5 meters is developed on the top of the reservoir. Satisfies the applicable heavy oil reservoir conditions of the method of the present invention.

[0068] The horizontal section of the double horizontal well is 400 meters long, the borehole diameter is 8.5 inches, and the well spacing is 5 meters. The horizontal production well is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com