Low-bending-modulus high-molecular pre-laid waterproof coiled material and preparation method thereof

A technology of flexural modulus and waterproof membrane, which is applied to building insulation materials, roofs using flexible materials, and building components, etc. It can solve the problems of large flexural modulus of coiled materials, collapse of lap joints, and difficulties in construction work, etc. problems, to achieve the effect of improving elongation performance, high elongation, and reducing the risk of cracking of lapped edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

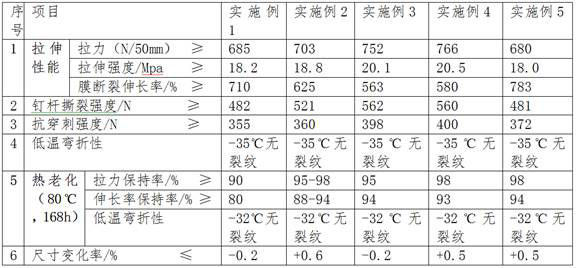

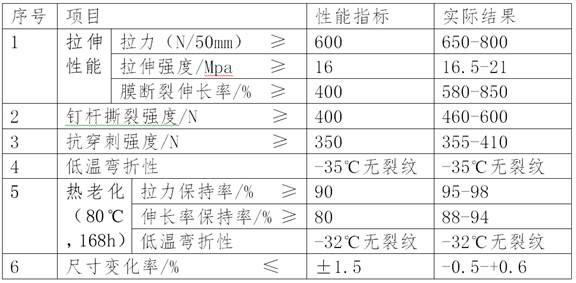

Examples

Embodiment 1

[0035] The main sheet of the low flexural modulus polymer pre-laid waterproof membrane of the present embodiment is composed of the following mass fraction components:

[0036] Linear low density polyethylene, 65 parts, density 0.918 g / cm 3 , Melt flow rate 1.8 g / 10min;

[0037] Block copolymer polypropylene, 15 parts, density 0.90g / cm 3 , Melt flow rate 2.20g / 10min;

[0038] Calcium carbonate masterbatch, 10 parts, carrier content 15%, melt flow rate 5.3g / 10min;

[0039] Compatibilizer, 10 parts, density 0.90g / cm 3 , Melt flow rate 3g / 10min;

[0040] The specific preparation method of the low flexural modulus polymer pre-laid waterproof membrane in the present embodiment comprises the following steps:

[0041] (1) drying and stirring

[0042] Add the measured materials into the drying and mixing tank in turn through the screw conveying device, adjust the air volume and temperature of the fan to deliver hot air, start stirring, keep the temperature at 105°C and stir for ...

Embodiment 2

[0052] Different from Example 1, the main sheet of the low flexural modulus polymer pre-laid waterproof membrane in this example is composed of the following mass fraction components:

[0053] Linear low density polyethylene, 55 parts, density 0.920 g / cm 3 , Melt flow rate 1.9g / 10min;

[0054] Block copolymer polypropylene, 20 parts, density 0.90g / cm 3 , Melt flow rate 2.30g / 10min;

[0055] Calcium carbonate masterbatch, 15 parts, carrier content 17%, melt flow rate 5.5g / 10min;

[0056] Compatibilizer, 10 parts, density 0.90g / cm 3 , Melt flow rate 3.2g / 10min.

Embodiment 3

[0058]Different from Example 1, the main sheet of the low flexural modulus polymer pre-laid waterproof membrane in this example is composed of the following mass fraction components:

[0059] Linear low density polyethylene, 50 parts, density 0.930 g / cm 3 , Melt flow rate 2.3g / 10min;

[0060] Block copolymer polypropylene, 25 parts, density 0.90g / cm 3 , Melt flow rate 2.60g / 10min;

[0061] Calcium carbonate masterbatch, 15 parts, carrier content 17%, melt flow rate 5.4g / 10min;

[0062] Compatibilizer, 10 parts, density 0.90g / cm 3 , Melt flow rate 3.6g / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com