High-elasticity composite high polymer material and preparation process thereof

A composite polymer, high-elasticity technology, used in other household appliances, household components, applications, etc., can solve the problems of sweating palms, difficult to take off gloves, airtight, etc., to improve the shedding speed, improve the practical application effect, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

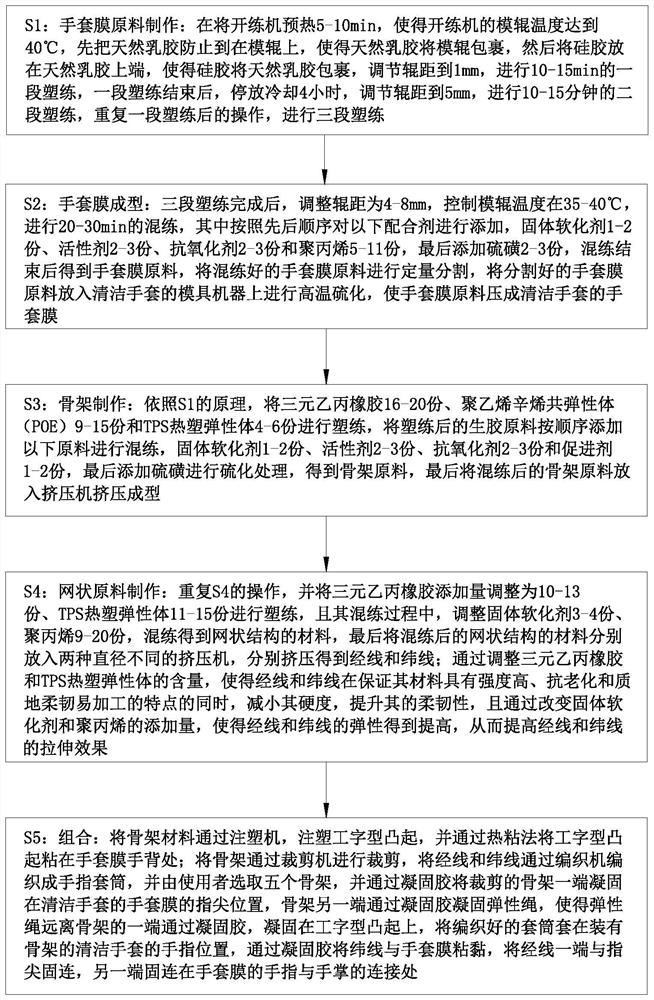

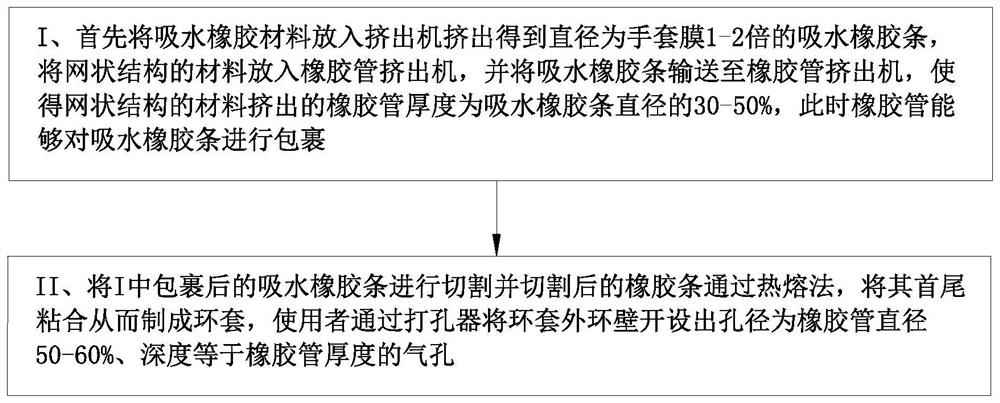

Method used

Image

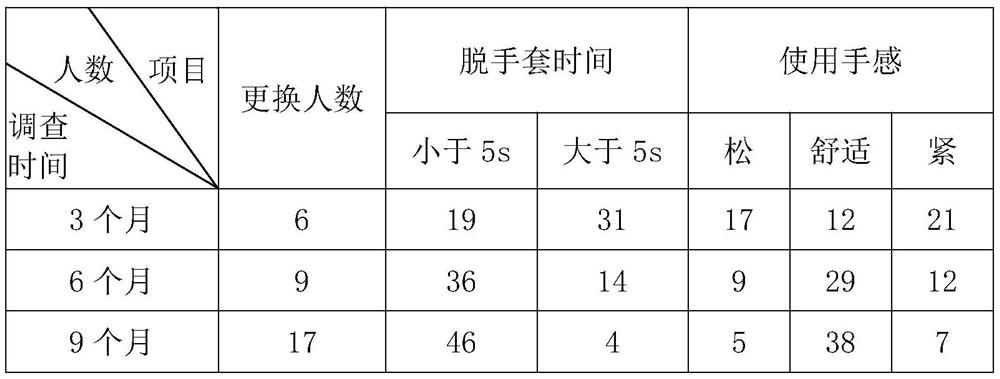

Examples

Embodiment approach

[0035] As an embodiment of the present invention, the diameter of the warp and weft in the network structure is 30%-50% of the skeleton diameter; the diameter of the weft is 60%-80% of the warp diameter, and the weft and warp are fixedly connected , the weft is fixed to the outer wall of the glove film; the skeleton is slidingly connected between the glove film and the weft; one end of the warp is fixed to the fingertip, and the other end is fixed to the joint between the fingers and the palm of the glove film; when in use, When the user's hand is larger than the glove film glove, the user's fingers are inserted into the glove, so that the fingertips push the skeleton to move away from the arm through the fingertips of the glove, and at the same time push the warp at the fingertips of the finger to stretch, so that the stretched warp During the process, the warp thread passes through the weft thread to drive the glove film at the finger to stretch evenly, reducing the deformati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com