High-early-activity phosphorus slag powder and preparation method thereof

A technology of active phosphorus and phosphorus slag powder, which is applied in cement production, etc., can solve the problems of low early pozzolan activity, low early activity improvement, and late activity loss, etc., to reduce the shielding effect, enhance ion migration ability, and binding ability weak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides a method for preparing phosphorus slag powder with high early activity. The preparation process includes: mixing phosphate rock, silica, coke and a vitreous structure regulator to form a mixture, wherein the vitreous structure regulator is an aluminum-containing raw material or a magnesium-containing material Raw materials, aluminum-containing raw materials are one or more of aluminum ore, bauxite, aluminum ash or aluminum slag, and magnesium-containing raw materials are one or more of magnesite, dolomite or serpentine. The mixture here may also include a vitreous network regulator, and the vitreous network regulator is any one or more of alkali metal oxides, hydroxides, sulfates, carbonates or chlorides. Preferably, for the phosphorus slag powder product used in reinforced concrete structures, the phosphorus slag powder produced with alkali metal chloride salt as the vitreous network regulator is not used, and the vitreous network regulator is an ...

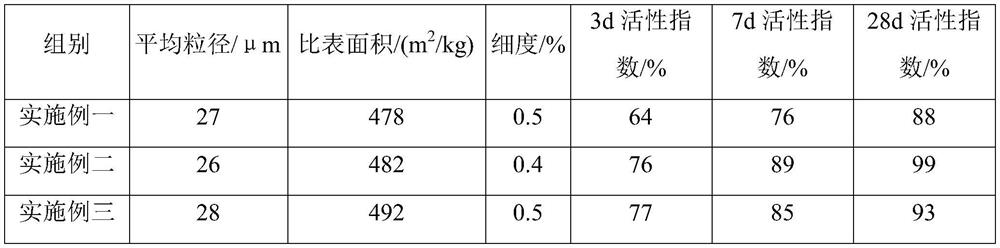

Embodiment 1

[0042] This embodiment provides a method for preparing early active phosphorus slag powder, first drying each raw material, and controlling the moisture content of each raw material to 2 o 3 , The content of MgO accounts for 10% of the total amount of raw materials except coke. The prepared raw materials were blended, then put into an electric furnace and heated to 900°C for 5 minutes, and then heated to 1400°C for 30 minutes to obtain a phosphorus slag melt. The phosphorus slag melt is discharged into saturated lime water with a pH value of 13 to obtain granular, loose and porous water-quenched phosphorus slag, and the water-quenched phosphorus slag is placed in a dry environment for draining treatment. Put the drained water-quenched phosphorus slag into a vertical mill for grinding, and use the waste heat of the electric furnace to dry it synchronously, and then use the wind separation process to wind it.

Embodiment 2

[0044] The difference between this example and Example 1 is that the raw materials used in this example are: 100 parts of phosphate rock, 25 parts of coke, 36 parts of magnesite and 39 parts of silica, after blending the raw materials with a moisture content of <1% , put into an electric furnace and heat up to 900° C. for 10 minutes, and continue to heat up to 1400° C. for 30 minutes to obtain a phosphorus slag melt. The subsequent treatment is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com