Intelligent edible oil squeezing equipment

A kind of edible oil, intelligent technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of low pressing efficiency and oil yield, and achieve the effect of high oil yield, easy operation, and easy adjustment of pressing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

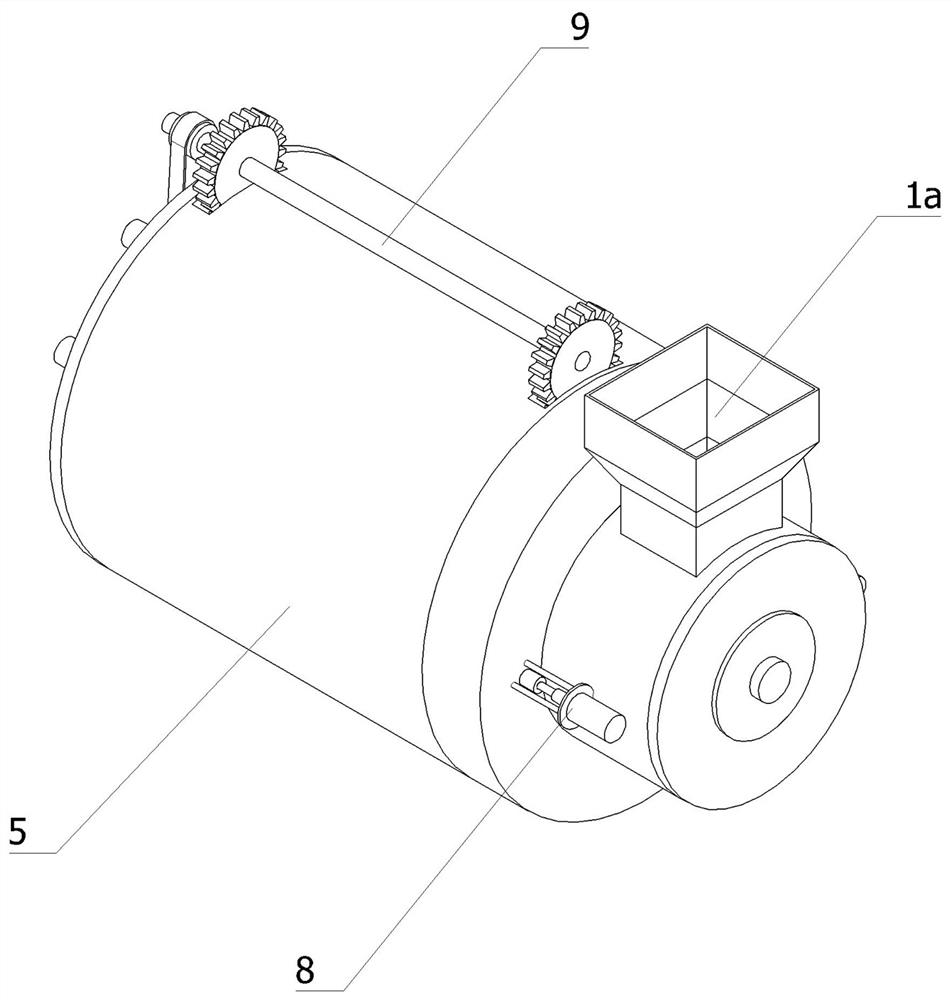

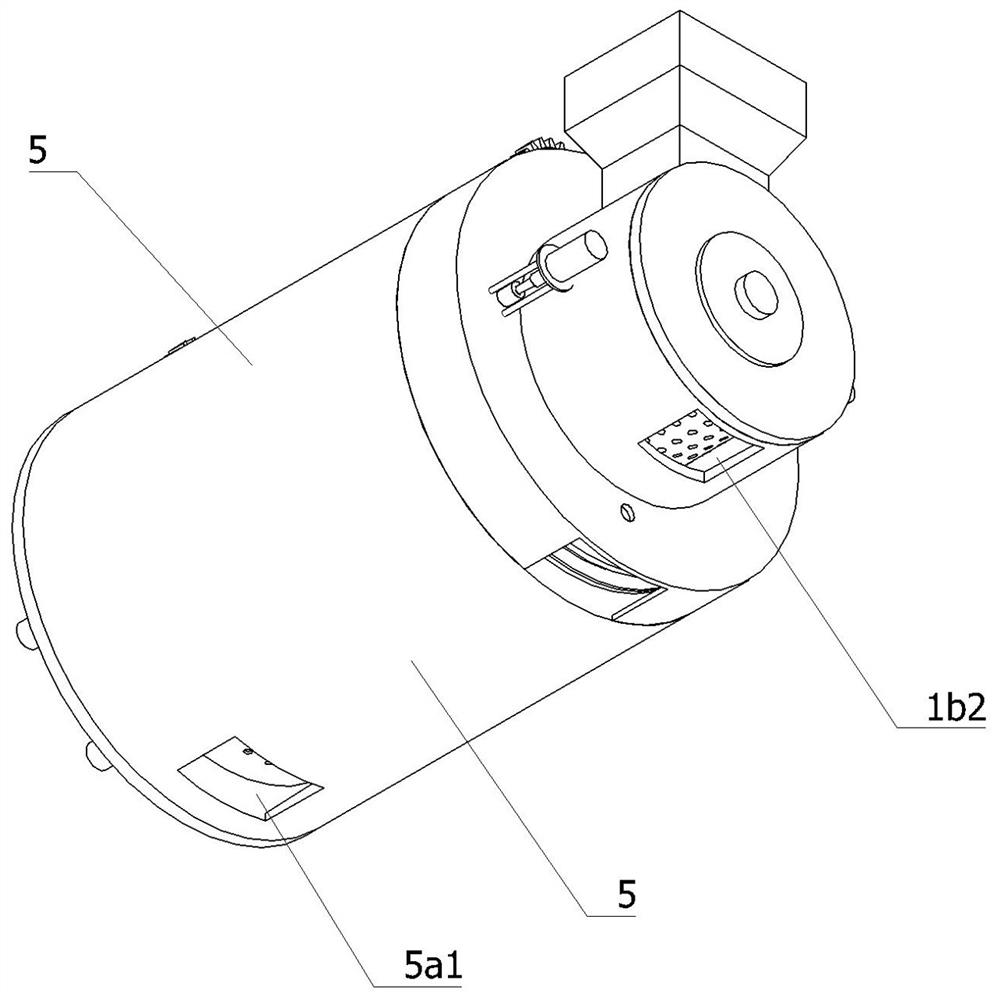

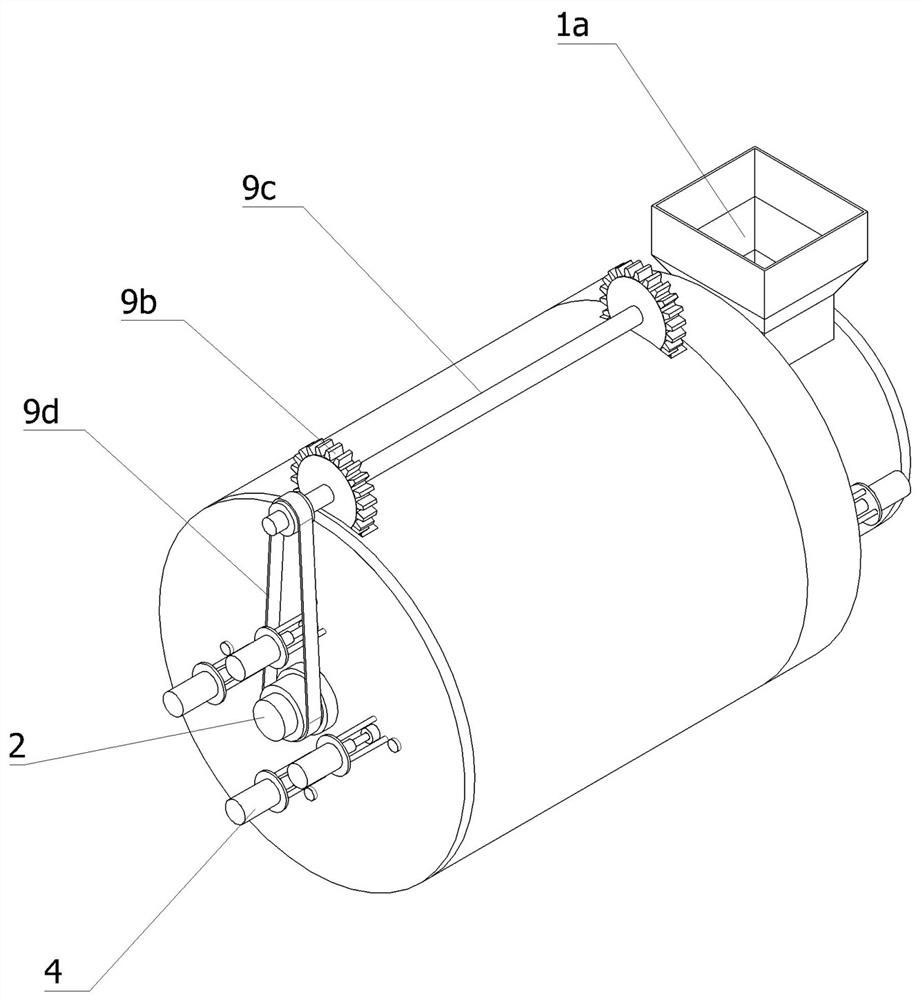

[0044] A device for intelligently squeezing edible oil, comprising a first cylinder shell 1 and a screw shaft 2 arranged therein, the device for squeezing edible oil also includes a second cylinder body 5, a rotating cylinder 6, a second cone ring 7, a second Two pressure drives 8 and a transmission assembly 9, the first shell 1 is provided with a feed port 1a, one end of the screw shaft 2 is provided with a driving device for driving its rotation, and one end of the first shell 1 is formed with the outer periphery of the screw shaft 2 The first opening, the first opening is provided with a first conical ring 3 coaxially sliding with the screw shaft 2, and the outer end of the first conical ring 3 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com