Over-alcoholized tobacco strip treatment method

A technology of alcoholizing flakes and flakes, which is applied in the field of tobacco processing, and can solve problems such as unreasonable storage methods, unsatisfactory storage conditions, and enhanced graininess of smoke, so as to control raw material storage and maintenance costs, relieve weak skeletons, and relax Feel good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

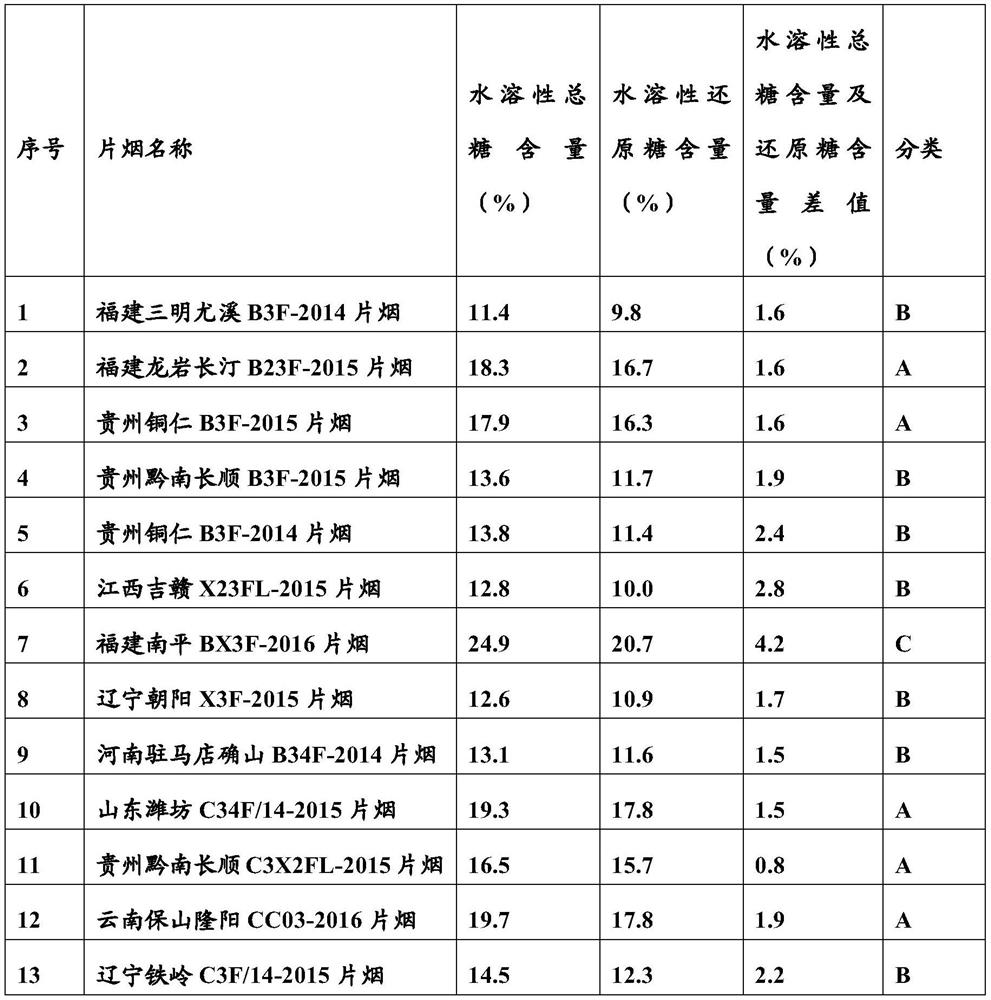

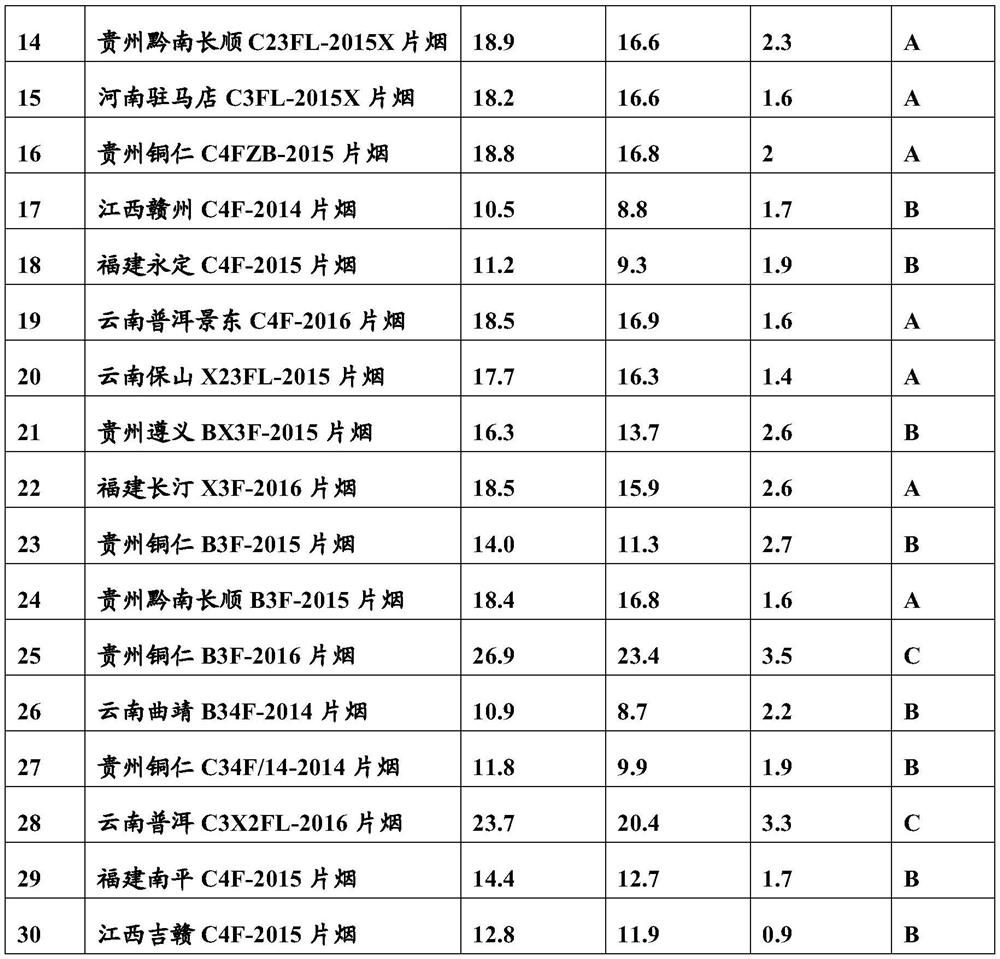

[0050] 1. According to the industry standard method (YC / T 159-2002 continuous flow method for the determination of water-soluble sugar in tobacco and tobacco products), detect and analyze the total amount of water-soluble sugar and water-soluble reducing sugar in the over-alcoholized tobacco leaf sample and the difference between the two. The results are shown in Table 1, and they were divided into three groups A, B, and C according to the results. The grouping criteria are as follows:

[0051] Group A: the content of water-soluble reducing sugar is 15.0-20.0%, and the difference between water-soluble total sugar and water-soluble reducing sugar is less than 3.0%;

[0052] Group B: Lamina with water-soluble reducing sugar content less than 15.0%, and the difference between water-soluble total sugar and water-soluble reducing sugar is less than 3.0%;

[0053] Group C: Laminar cigarettes with water-soluble reducing sugar content greater than 20.0%, and the difference between wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com