Broadband wave-absorbing metamaterial flexible sheet based on carbon-series material and preparation method of broadband wave-absorbing metamaterial flexible sheet

A flexible sheet, broadband technology, used in electrical components, magnetic/electric field shielding, antennas, etc., to reduce electromagnetic radiation, reduce the cross-sectional area of radar scattering, and achieve electromagnetic compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a flexible sheet of a broadband wave-absorbing metamaterial based on a carbon-based material, comprising the following preparation steps:

[0045] Step 1. The dielectric layer is divided into every other unit cell according to the unit size of the periodic resonant structure. P The size of the hole is mechanically punched in the shape of a double-layer concentric cylinder, and the diameter and height of the lower cylindrical hole are respectively w and t , the diameter and height of the upper cylindrical hole are y and x , see Figure 7 for the photo of the dielectric plate with the holes;

[0046] Step 2. Clean the small hole side of the dug-out dielectric plate with absolute ethanol, and apply metal materials such as copper film or aluminum film, or other materials with microwave total reflection ability as the reflective layer; this paste reflects The above steps can also be completed in the last step;

[0047] Step 3, stirring the graphene...

Embodiment 1

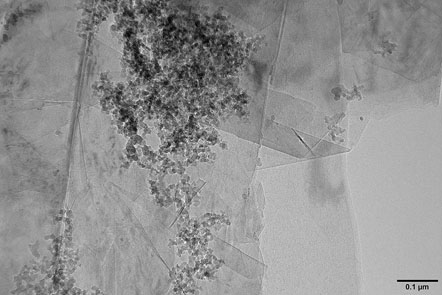

[0054] The broadband wave-absorbing metamaterial flexible patch based on carbon-based materials consists of a two-layer structure: the bottom layer is a metal reflective layer, and the upper layer is a 2.7mm dielectric layer. The dielectric layer is embedded with double-layer cylindrical carbon systems arranged periodically. The complex unit array, the structure diagram is as follows Figure 4 As shown, the electromagnetic wave is incident from the Z direction of the top layer; the embedded double-layer cylindrical carbon-based composite unit array uses a mixture of graphene powder and epoxy resin with a weight ratio of 15%, and the electromagnetic parameters are as follows: image 3 shown. The dimensions of the resonance unit are as follows: P = 13mm, x = 1.5mm, y = 4mm, t = 1.2mm and w =2.2mm, the dielectric board is polyester film (the relative dielectric constant is 3.8, the loss tangent is 0.03), the thickness of the dielectric board h = 2.7 mm; the reflective s...

Embodiment 2

[0058] The broadband wave-absorbing metamaterial flexible patch based on carbon-based materials includes a two-layer structure: the bottom layer is a copper film reflective layer, the upper layer is a 2.7mm polycarbonate film, and the dielectric layer is embedded with double-layer cylinders arranged periodically The unit array of carbon-based composites, the structure diagram is as follows Figure 4 As shown, the electromagnetic wave is incident from the Z direction of the top layer; the embedded double-layer cylindrical carbon-based composite unit array uses a mixture of graphene powder and polyurethane resin with a weight ratio of 15%. The dimensions of the resonance unit are as follows: P = 13mm, x = 1.5mm, y = 4mm, t = 1.6mm and w =2.2mm, the dielectric board is polycarbonate film (relative dielectric constant is 2.9, loss tangent is 0.01), the thickness of the dielectric board h = 3.1 mm; the reflective surface is a copper film (σ =5.8×107S / m), with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com