Ultrahigh-capacity zinc-cobalt battery positive electrode and self-activation preparation method thereof

A zinc-cobalt battery, self-activation technology, applied to battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of low actual capacity, low utilization rate of zinc-cobalt battery positive electrode materials, etc., to achieve enhanced valence conversion capability, electrolytic Uniform liquid distribution and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A self-activating preparation method for an ultra-high-capacity zinc-cobalt battery positive electrode:

[0050] (1) Assemble the traditional cobalt tetraoxide electrode into a zinc-cobalt battery with an air permeability of 75%. The preparation method of the traditional cobalt tetraoxide nanosheet electrode is: dissolve 0.5mmol cobalt nitrate hexahydrate, 4.5mmol ammonium fluoride and 8mmol urea in 40mL In deionized water, stir for 5 minutes to prepare the precursor solution, and pour it into a 50mL hydrothermal kettle lined with polytetrafluoroethylene; place the foamed nickel current collector in the hydrothermal kettle and completely submerge it in the precursor solution , close the hydrothermal kettle, and heat it at a temperature of 120°C for 9 hours to prepare a current collector loaded with a precursor; wash the current collector loaded with a precursor, dry it at a temperature of 60°C for 3 hours, and place it in a muffle furnace. Raise the temperature to 350°C...

Embodiment 2

[0056] A self-activating preparation method for an ultra-high-capacity zinc-cobalt battery positive electrode:

[0057] (1) Assembling the traditional cobalt tetroxide electrode into a zinc-cobalt battery with an air permeability of 75%, the preparation method of the traditional cobalt tetroxide electrode is the same as in Example 1;

[0058] (2) Charge and discharge the zinc-cobalt battery with a current density of 3.0A / g, and the charge and discharge times are each 15 minutes;

[0059] (3) 100 self-activation cycles under the charging and discharging conditions of step (2) to obtain an ultra-high-capacity zinc-cobalt battery electrode.

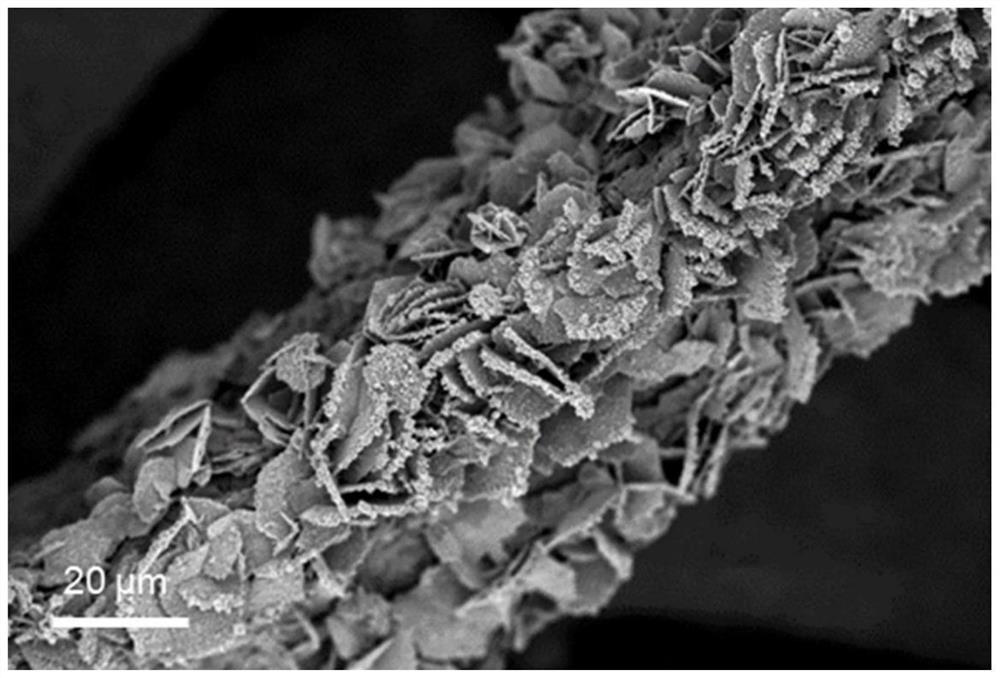

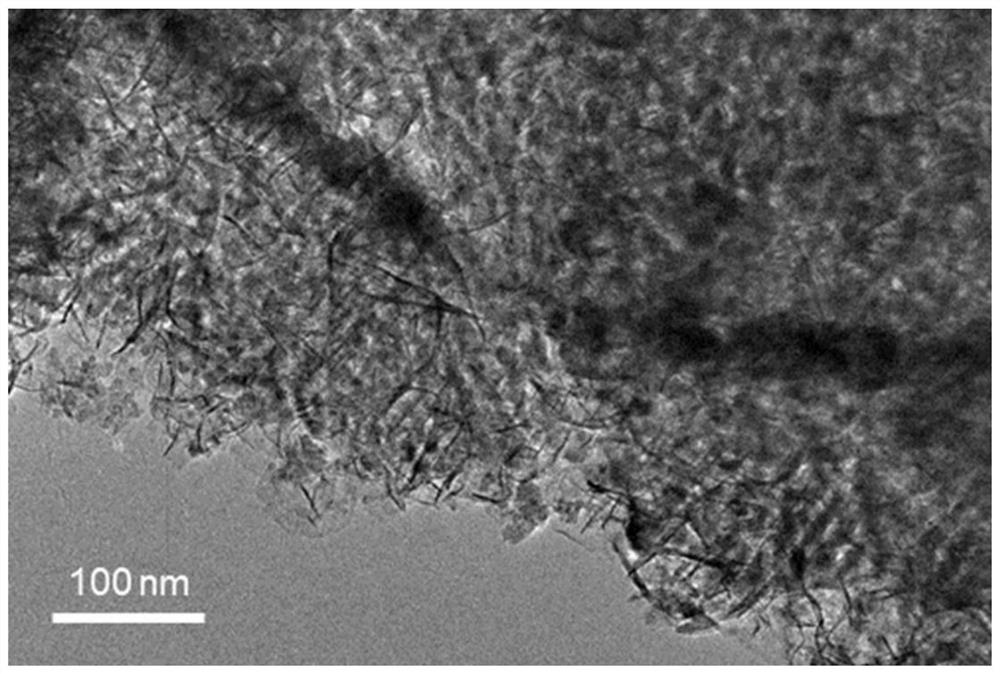

[0060] The ultra-high-capacity zinc-cobalt battery positive electrode prepared in this example shows the low-magnification microscopic morphology of the scanning electron microscope. Figure 7 , the high-magnification microscopic topography of scanning electron microscope is shown in Figure 8 , and the low-magnification microscopic morpho...

Embodiment 3

[0063] A self-activating preparation method for an ultra-high-capacity zinc-cobalt battery positive electrode:

[0064] (1) Assembling the traditional cobalt tetroxide electrode into a zinc-cobalt battery with an air permeability of 75%, the preparation method of the traditional cobalt tetroxide electrode is the same as in Example 1;

[0065] (2) Charge and discharge the zinc-cobalt battery with a current density of 3.0A / g, and the charge and discharge times are each 15 minutes;

[0066] (3) 150 self-activation cycles under the charging and discharging conditions of step (2) to obtain an ultra-high-capacity zinc-cobalt battery electrode.

[0067] In this example, a material with a multi-level nanosheet structure is obtained. The first-level nano-sheet structure uniformly covers the surface of the nickel foam with a length of 10 μm, and the thickness of the second-level ultrafine nano-sheet is 4 nm. After 150 self-activation cycles, the discharge capacity of the zinc-cobalt se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com