Preparation method of carbon quantum dot modified NCM ternary positive electrode material and prepared NCM ternary positive electrode material

A technology of carbon quantum dots and positive electrode materials, applied in positive electrodes, electrical components, battery electrodes, etc., to achieve the effects of good lithium ion transport capacity, enhanced gram capacity, and enhanced electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

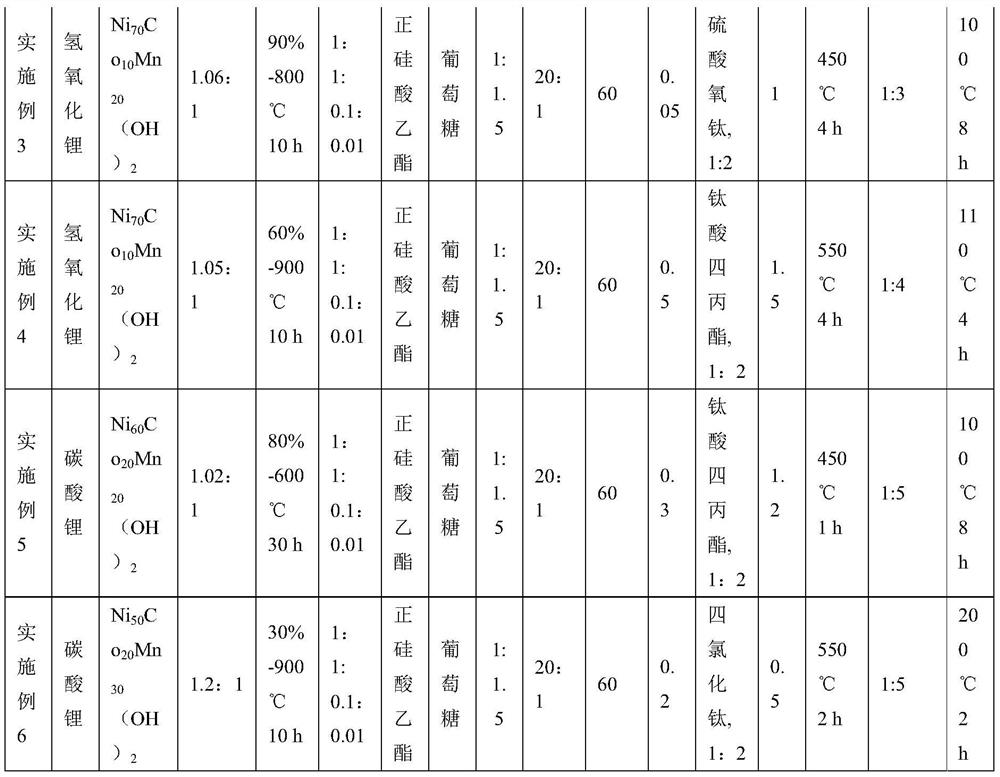

Examples

Embodiment 1

[0054] The preparation method of the NCM ternary cathode material of the Rattle-type structure modified by carbon quantum dots comprises the following steps:

[0055] Step 1. Coating the middle layer

[0056] Combining lithium hydroxide with commercial ternary precursor Ni 70 co 10 mn 20 (OH) 2 According to the ratio of lithium element to the total molar ratio of nickel, cobalt and manganese elements in the precursor of 1.08:1, the materials were weighed and mixed evenly, and the mixed materials were sintered once for 10 hours under the condition that the volume concentration of oxygen atmosphere was 50% and the temperature was 800°C. Then pulverize and sieve 200 mesh sieves to obtain primary sintered material A;

[0057] Disperse the sintered material A into absolute ethanol, add ammonia water and methyl orthosilicate after stirring, react at room temperature and pressure for 5 hours, filter, wash with alcohol, and dry in vacuum at 120°C. The obtained material is sample B...

Embodiment 2

[0065] The preparation method of the NCM ternary cathode material of the Rattle-type structure modified by carbon quantum dots comprises the following steps:

[0066] Step 1. Coating the middle layer

[0067] Combining lithium hydroxide with commercial ternary precursor Ni 70 co 10 mn 20 (OH) 2 According to the ratio of lithium element to the total molar ratio of nickel, cobalt and manganese elements in the precursor of 1.07:1, the materials were weighed and mixed evenly, and the mixed materials were sintered once for 12 hours under the condition that the volume concentration of the oxygen atmosphere was 70% and the temperature was 850°C. Then pulverize and sieve 200 mesh sieves to obtain primary sintered material A;

[0068] Disperse the sintered material A into absolute ethanol, add ammonia water and tetraethyl orthosilicate after stirring, react at room temperature and pressure for 5 hours, filter, wash with alcohol, and dry in vacuum at 120°C. The obtained material is ...

Embodiment 3

[0076] The preparation method of the NCM ternary cathode material of the Rattle-type structure modified by carbon quantum dots comprises the following steps:

[0077] Step 1. Coating the middle layer

[0078] Combining lithium hydroxide with commercial ternary precursor Ni 70 co 10 mn 20 (OH) 2 According to the ratio of lithium element to the total molar ratio of nickel, cobalt and manganese elements in the precursor of 1.06:1, the materials were weighed and mixed evenly, and the mixed materials were sintered once for 10 hours under the condition that the volume concentration of the oxygen atmosphere was 90% and the temperature was 800°C. Then pulverize and sieve 200 mesh sieves to obtain primary sintered material A;

[0079] Disperse the sintered material A into absolute ethanol, add ammonia water and tetraethyl orthosilicate after stirring, react at room temperature and pressure for 5 hours, filter, wash with alcohol, and dry in vacuum at 120°C. The obtained material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com