Lithium ion battery coating process pole piece drying system and process method thereof

A lithium-ion battery and drying system technology, which is applied to the field of pole piece drying systems in the coating process of lithium-ion batteries, can solve problems such as inability to contain material components, achieve high air flow and temperature control accuracy, good drying effect, and Uniform and stable effect of drying temperature field and wind field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

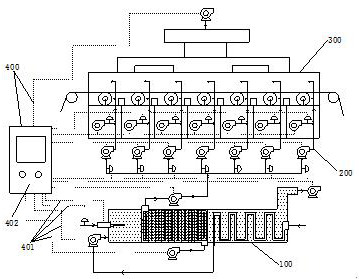

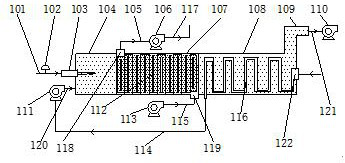

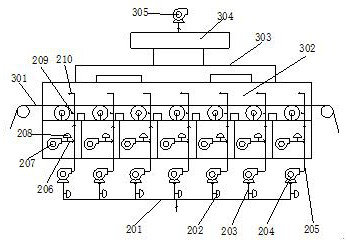

[0036] Such as Figure 1-4As shown, a lithium-ion battery coating process pole piece drying system, the pole piece drying system is composed of a hot air station 100, a hot air transmission and control system 200, a coating machine oven 300, and a coating machine control system 400. The hot air station 100 The hot air transmission and control system 200 is connected with the hot air transmission and control system 200 through the hot air delivery pipeline 117, and the hot air transmission and control system 200 is connected with the coating machine oven 300 through the hot air supply pipe 209 at the lower part of the oven and the hot air supply pipe 210 at the upper part of the oven. The control element is connected with the coating machine control system 400 through the system control circuit 401. The hot air station 100 is composed of a combustion chamber 104, a heat storage and heat exchange chamber 107, and a smoke chamber 108. The three chambers are an integral structure c...

Embodiment 2

[0039] Such as Figure 5 As shown, a process method of a pole piece drying system in a lithium-ion battery coating process includes the following steps:

[0040] S1: Hot air preparation. The fuel is input into the combustion chamber of the hot air station for combustion and oxidation to generate hot flue gas rich in heat. The hot flue gas enters the heat storage and heat exchange chamber to convert heat energy to natural cold air input from the outside to produce clean hot air. The flue gas enters the smoke chamber, further converts heat to the combustion-supporting air, and then is discharged into the atmosphere from the smoke exhaust machine. During the hot air preparation process, the fuel is natural gas, liquefied petroleum gas or coal gas. During the hot air preparation process, the hot flue gas The temperature is controlled at 300-600°C, the outlet temperature of clean hot air is controlled at 150-250°C, and the discharge temperature of cold flue gas is <55°C;

[0041] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com