Ceramic bearing structure for rotor shaft and water-lubricated screw compressor

A technology of screw compressors and ceramic bearings, applied in the directions of shafts and bearings, rotating bearings, bearings, etc., can solve the problems of low assembly efficiency, occupation, long length of the water-lubricated screw compressor host, etc., and achieve easy assembly or disassembly. The process is simple, the lubrication effect is good, and the assembly efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

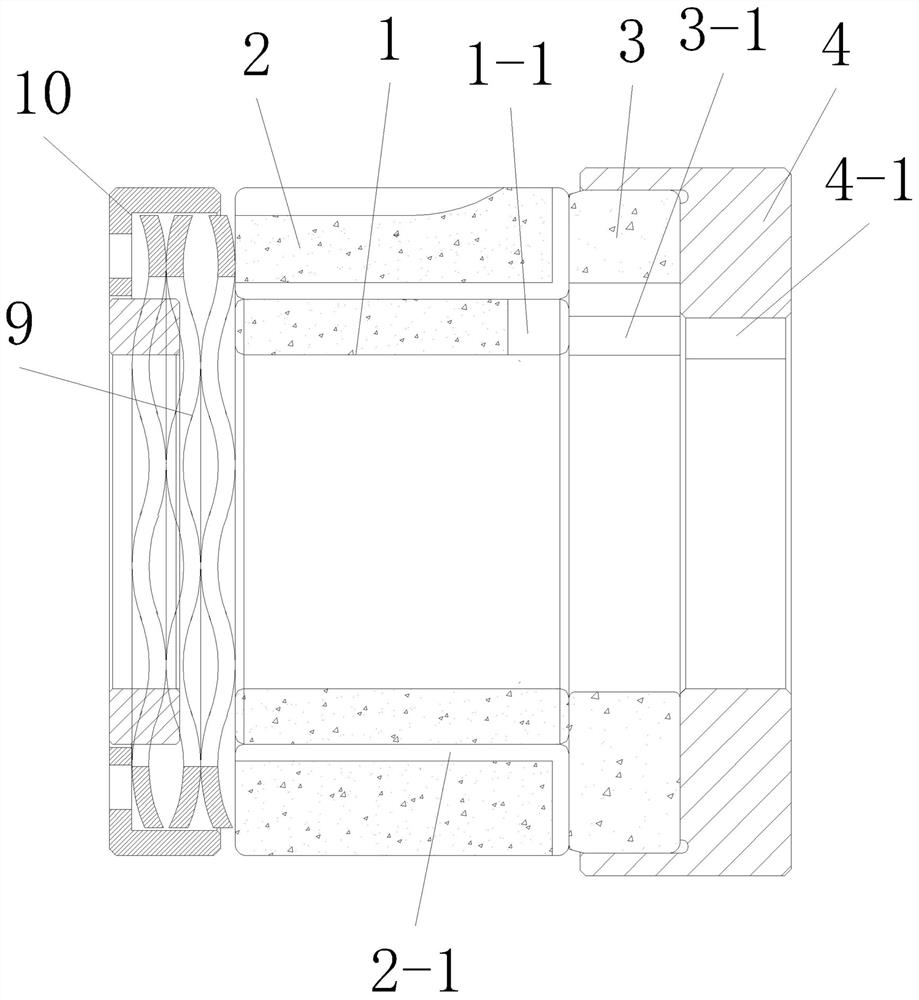

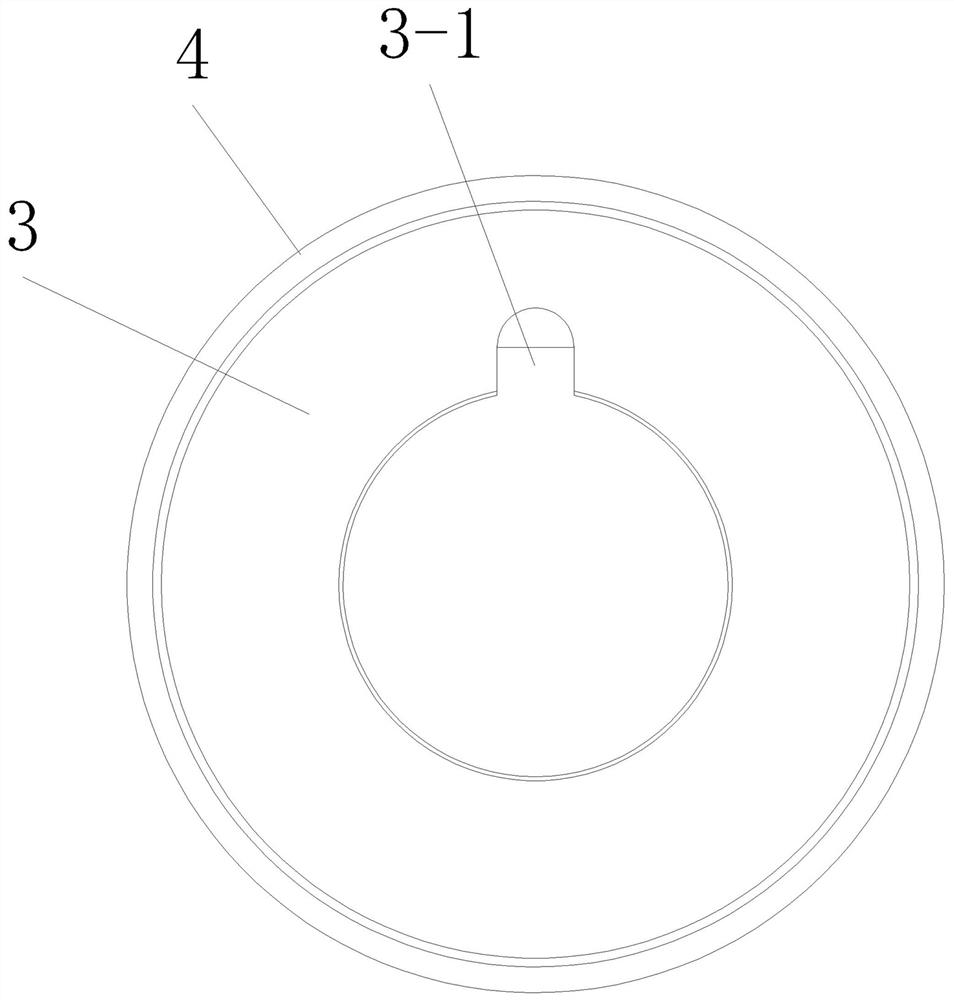

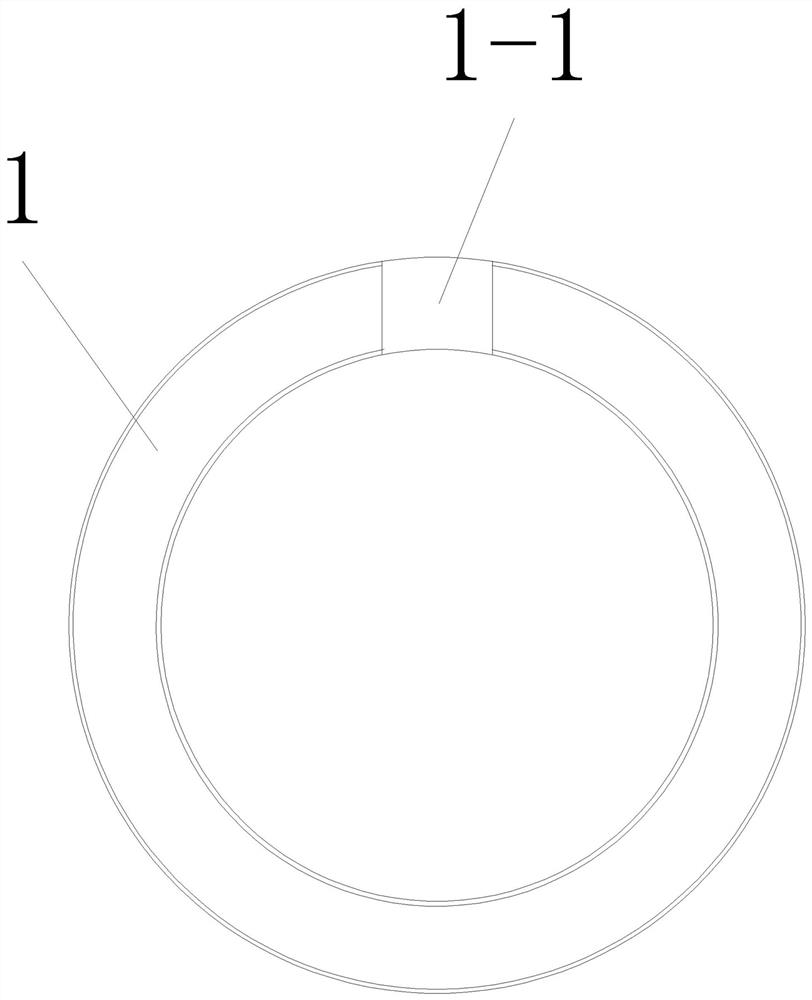

[0024] Such as Figure 1 to Figure 4 As shown in , the ceramic bearing structure for the rotor shaft of the present invention includes a sliding bearing 1, a bearing bush 2, a thrust bearing 3, and a thrust bearing seat 4, and the thrust bearing 3 is fixedly connected in the thrust bearing seat 4, and the sliding bearing 1, the thrust bearing 3 and The thrust bearing housing 4 is provided with an inner hole for socketing the rotor shaft, and the side walls of the inner holes of the sliding bearing 1, the thrust bearing 3 and the thrust bearing housing 4 are respectively provided with a first key groove 1 for key connection with the rotor shaft -1. The second keyway 3-1, the third keyway 4-1, the first keyway 1-1, the second keyway 3-1, and the third keyway 4-1 can be connected end to end to form a large keyway, sliding bearing 1, bearing bush 2. The thrust bearing 3 is made of ceramic material. In this embodiment, silicon carbide material can be used, and zirconia material can...

Embodiment 2

[0026] Such as Figure 5As shown in , the water-lubricated screw compressor of the present invention includes a compressor main body, a screw rotor 6 is arranged in the cylinder of the compressor main body, and a bearing hole is arranged on the casing of the compressor main body, and a bearing hole such as The ceramic bearing structure and the elastic pretensioner for the rotor shaft described in Embodiment 1, the elastic pretensioner includes a wave spring 9 and a spring seat 10, the wave spring 9 is arranged in the spring seat 10, and the spring seat 10 is also provided with a shaft sleeve, the wave spring 9 is limited between the outer wall of the sleeve and the inner wall of the spring seat 10, the sleeve is sleeved on the screw rotor 6, the spring seat 10 is limited in the bearing hole, and the side wall of the bearing hole A positioning screw 8 is provided, and the positioning screw 8 is in contact with and pressed against the bottom of the positioning groove 2-2 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com