Valve assembly for controlling the gas pressure, fuel system comprising a valve assembly for controlling the gas pressure

A fuel system and gas pressure technology, applied in the direction of charging system, valve device, valve details, etc., can solve the problems of limited mechanical loadability, bending, etc., and achieve the effect of reducing load and improving functional reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

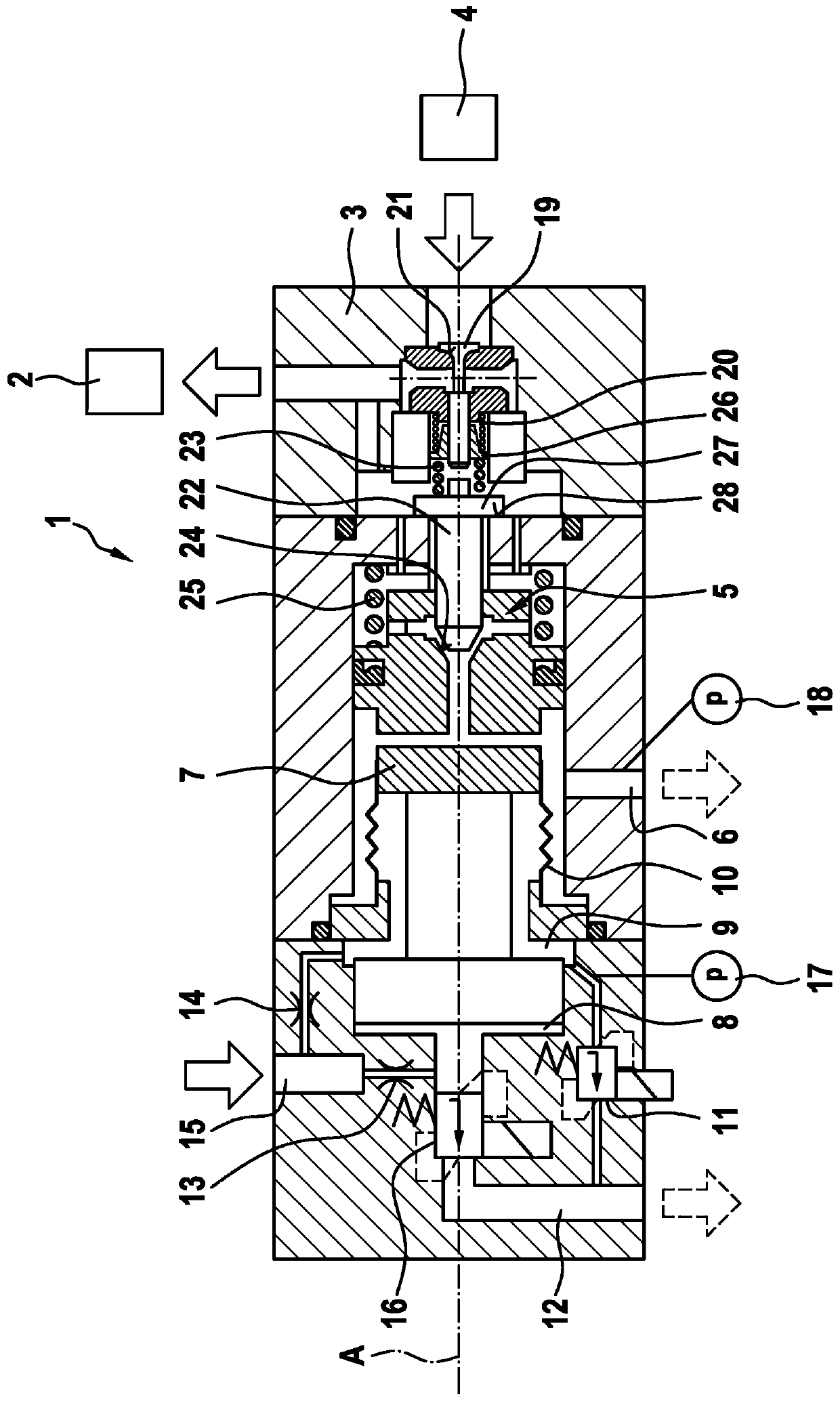

[0022] The valve assembly 1 according to the invention shown in the drawing is used for gas pressure regulation in a gas rail 2 of a fuel system for supplying a gaseous fuel to an internal combustion engine, wherein the gas may in particular be natural gas. For this purpose, the valve arrangement 1 shown has a first valve 3 for connecting the gas rail 2 to the high-pressure accumulator 4 and a second valve 5 for connecting the gas rail 2 to the gas return 6 . The first valve 3 has a valve lifter 19 which can be moved back and forth, which is prestressed against a valve seat 21 by means of a spring 20 . The second valve 5 has a valve piston 22 which is prestressed against a valve seat 24 by means of a spring 23 . For this purpose, the spring 34 is supported on the one side on the valve piston 22 and on the other side on the spring plate 26 connected to the valve tappet 19 . This is possible because the valve piston 22 and the valve tappet 19 are arranged coaxially, ie lie on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com