high speed balanced pdc drill bit for oil drilling

A technology for oil drilling and drill bits, applied in drill bits, drilling equipment, drill pipes, etc., can solve the problems of great difference in rotational linear speed, loss of performance of drill bits, and reduction of hardness of drill bits, so as to reduce revolution speed, prolong service life, The effect of reducing the rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

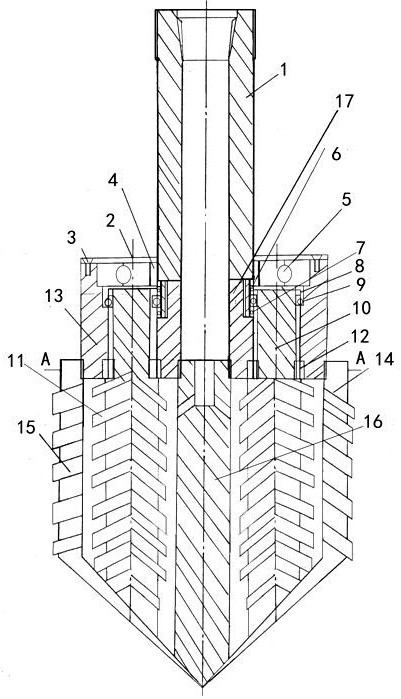

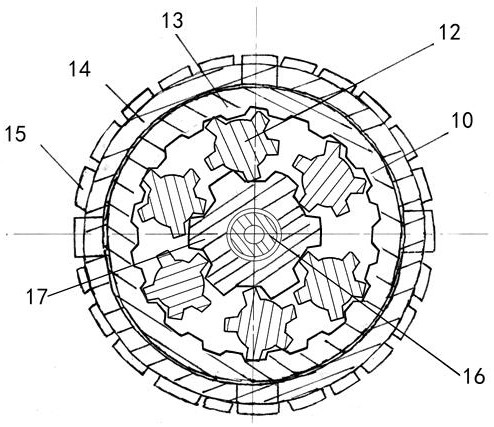

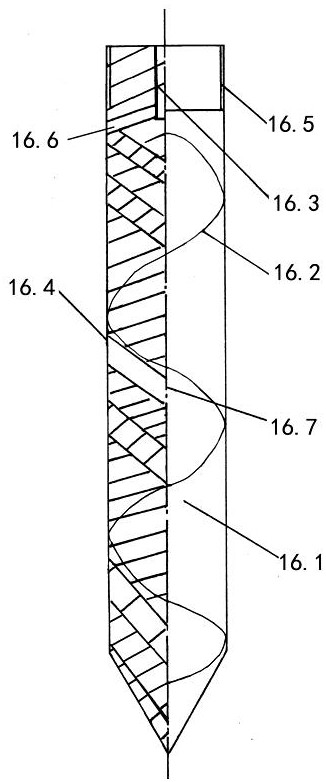

[0028] Example 1, reference Figure 1-2 , A high-speed balance PDC drill bit referred to in the present invention, including an upper joint 1, a hierarchical bearing 5, a speeding capacitor 8, a speed bearing 9, a milling drill body 10, a speed meter 12, a boring transfer The sleeve 13, the boring drill body 14, the center drill bit 16, and the upper end of the upper joint 1 connect the upper end of the center drill bit 16 by the upper end of the joint 17, the central drill bit 16 is a cylindrical structure; the boring The drill head body 14 is a cylindrical structure, and is located at the outermost ring of the central drill bit 16, the upper end of the boring drill body 14 drives the connection by the boring and milling transfer sleeve 13; the cavity between the boring drill body 14 and the central drill bit 16 There is a multi-group milling drill body 10, and the outer wall of each milling drill body 10 is provided with a transmission speed mesh 12, and the tooth teeth and borin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com