Elastic body, vertical elastic structure and vertical elastic support

An elastic structure and elastomer technology, applied in bridge parts, bridge materials, bridges, etc., can solve the problems of high installation height, small curvature of the demeanor curve, affecting the operation status of bridges, etc., and achieve the effect of meeting the rigidity requirements and reducing the installation height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

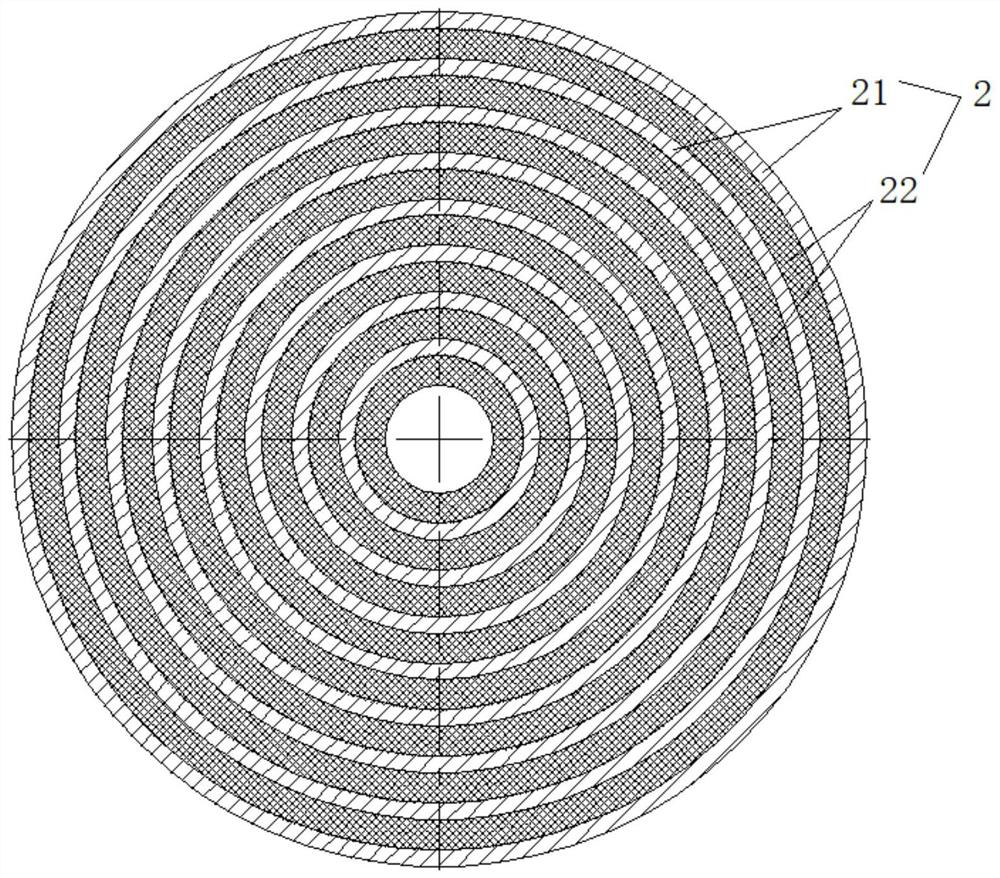

[0049] see figure 1 , this embodiment proposes an elastic body, the elastic body 2 is a multi-layer structure, the multi-layer structure is a layer of rigid parts 21 and a layer of elastic parts 22 alternately arranged, the outermost layer of the elastic body 2 is The rigid part 21, the elastic part 22 is connected with the rigid parts 21 on both sides thereof.

[0050] Regarding the material, the elastic member 22 is rubber, the rigid member 21 is a steel plate, and the rubber is vulcanized and bonded to the steel plates on both sides.

[0051]The elastic body 2 is composed of one layer of steel plate and one layer of rubber. Its structure is completely different from that of springs, ordinary laminated rubber and rubber bodies. The elastic body 2 can realize vertical displacement and can be adjusted according to the displacement. The structural size of the elastic body 2 can not only be used in the bearing of bridge construction, but also can be used independently in any pl...

Embodiment 2

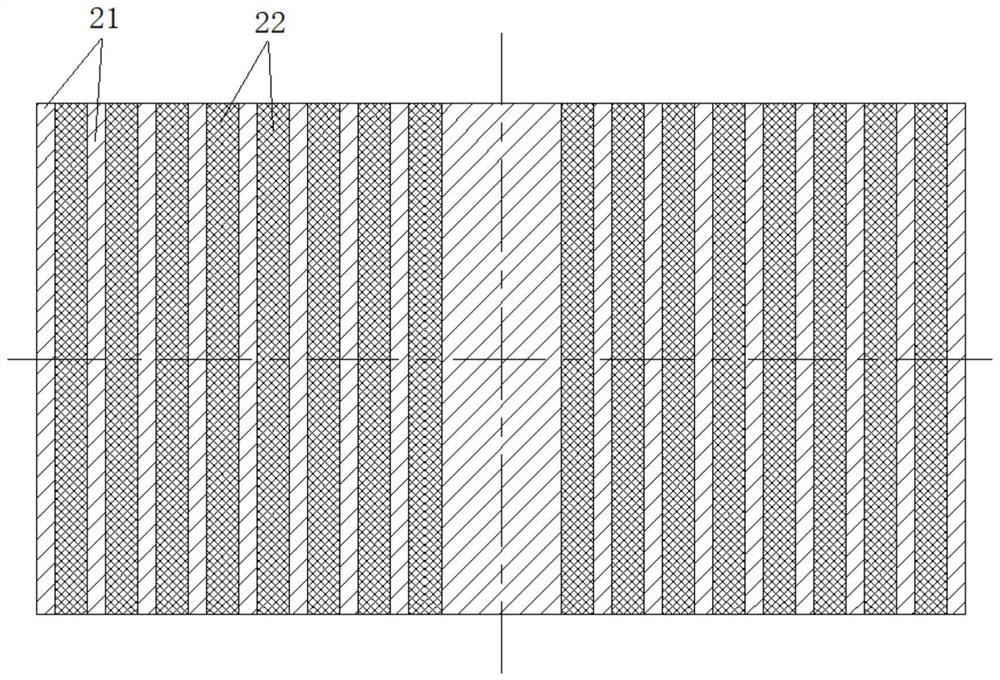

[0054] see figure 2 , The difference between this embodiment and Embodiment 1 is that: the rigid member 21 and the elastic member 22 are plate-shaped, and the cross-section of the formed elastic body 2 is rectangular.

Embodiment 3

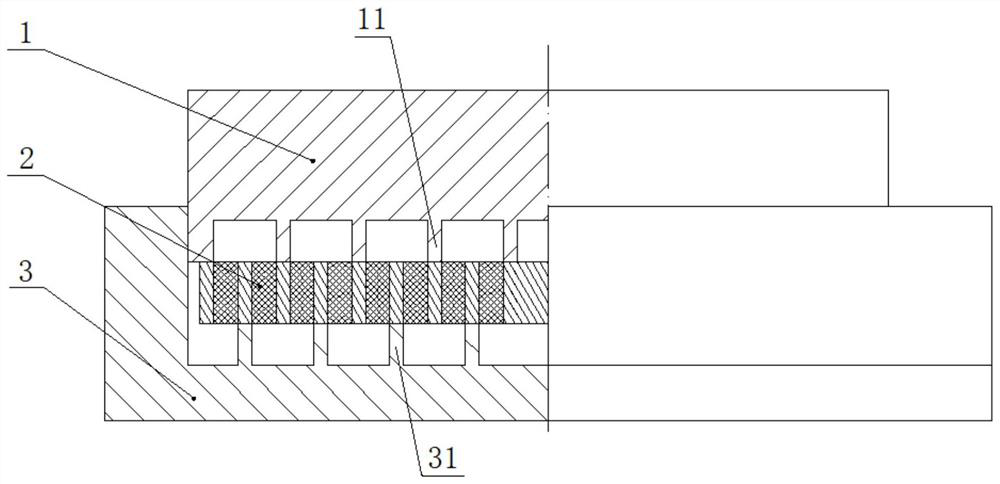

[0056] see image 3 , this embodiment proposes a vertical elastic structure, including an upper part 1 and a lower part 3, the elastic body 2 described in embodiment 1 or embodiment 2 is arranged between the upper part 1 and the lower part 3, and the upper part 1 There are several first protruding teeth 11, which are in rigid contact with the upper surface of the rigid part 21 of the elastic body 2, and the lower part 3 is provided with several second protruding teeth 31, which are in contact with the rigid part 21 of the elastic body 2. The lower surface of the first protruding teeth 11 and the second protruding teeth 31 are arranged in a staggered manner.

[0057] In this embodiment, the widths of the first protruding teeth 11 and the second protruding teeth 31 are equal to the thickness of the rigid member 21; the upper part 1 and the lower part 3 are rigid bodies.

[0058] The lower part 3 has a groove, the second protruding tooth 31 and the elastic body 2 are located in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com