Assembled power distribution cabinet column section bar and assembling method thereof

A power distribution cabinet and assembled technology, which is applied in the field of column profiles and assembly of fully assembled power distribution cabinets, can solve the problems that the surface anti-corrosion treatment cannot achieve full coverage, local anti-corrosion ability is poor, and the opening structure is single, so as to avoid Port scratches, high level of safety protection, and scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

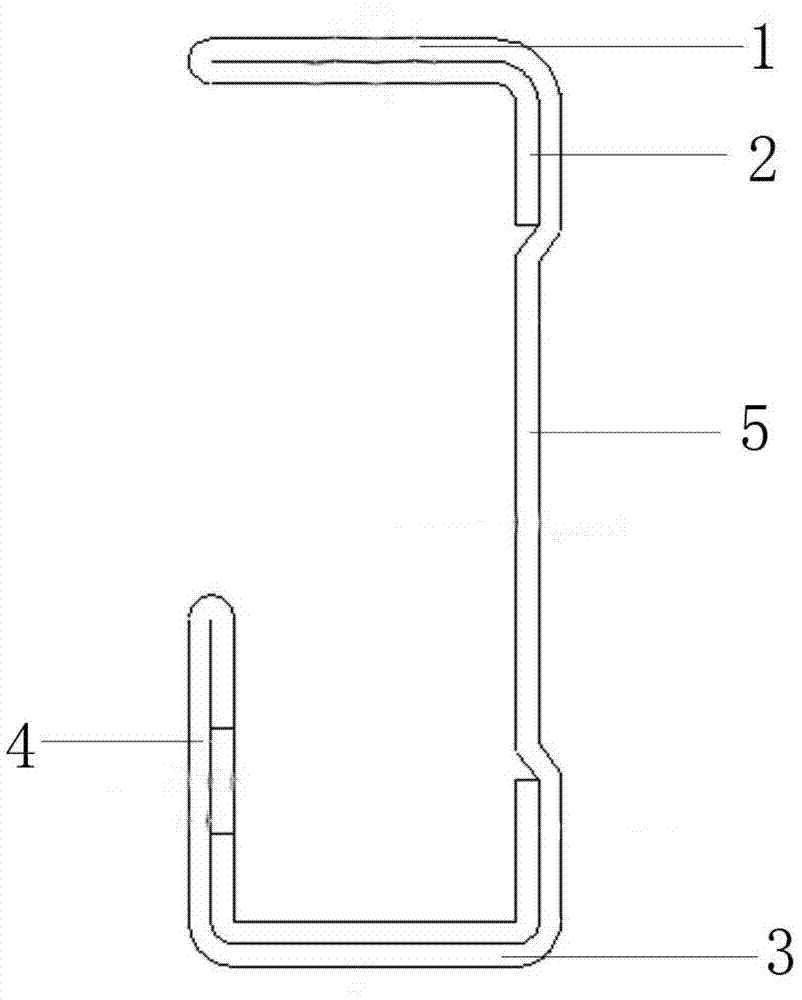

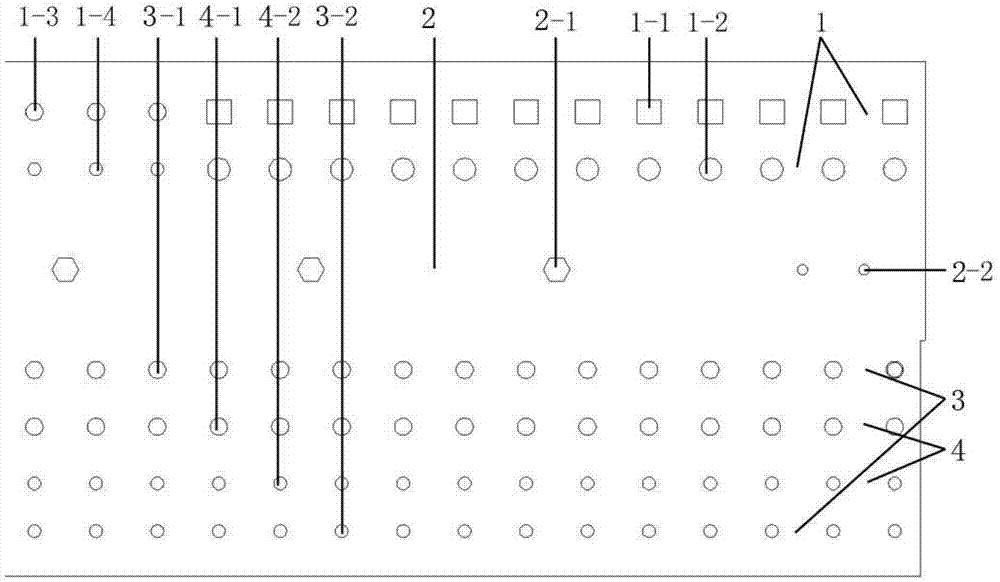

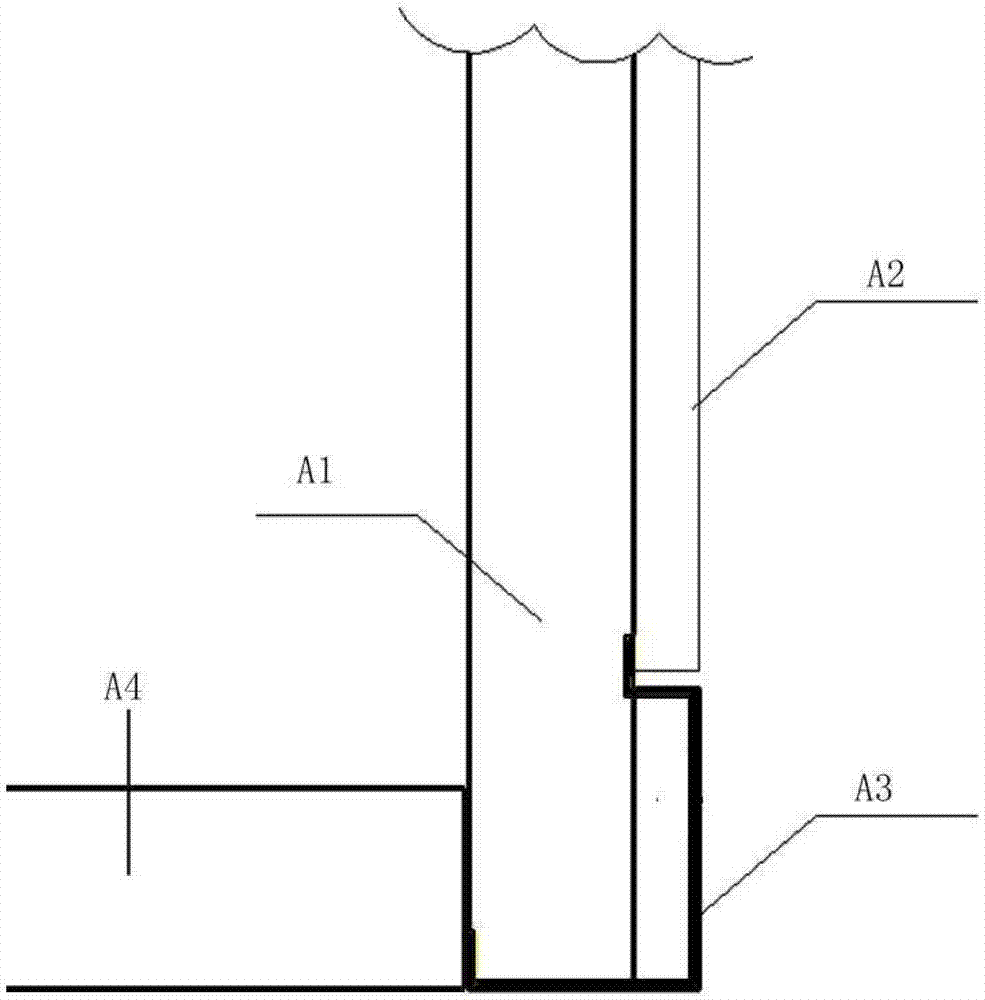

[0027] Such as Figure 1-2 As shown, an assembled power distribution cabinet column profile is made of sheet metal punching, bending, and lamination. composition, the first folding surface 1 is perpendicular to the second folding surface 2, the second folding surface 2 is perpendicular to the third folding surface 3, the third folding surface 3 is perpendicular to the fourth folding surface 4, and the first folding surface A folded surface 1 has a double-layer structure, and there are 12 square holes 1-1 and 12 round holes 1-2 respectively at both ends of the first folded surface 1, and the square holes 1-1 and the round holes 1-2 Overlapping respectively, the square hole 1-1 is on the outer layer of the first folding surface 1, the round hole 1-2 is on the inner layer of the first folding surface 1, and the middle part of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com