Concrete prefabricated culvert pipe processing method

A processing method and concrete technology, applied in the direction of manufacturing tools, metal processing equipment, reinforced molding, etc., can solve problems such as insufficient precision, changes in the diameter of the steel skeleton, and influence on the preparation of culverts, and achieve the effect of maintaining horizontality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

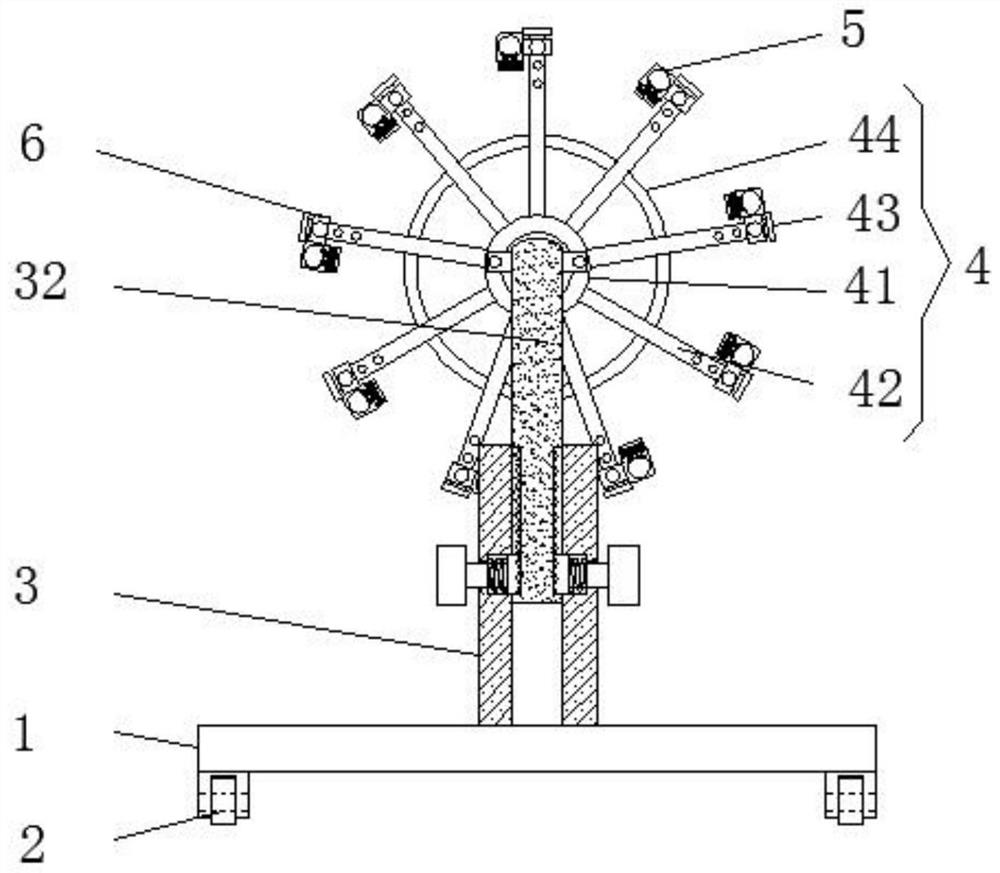

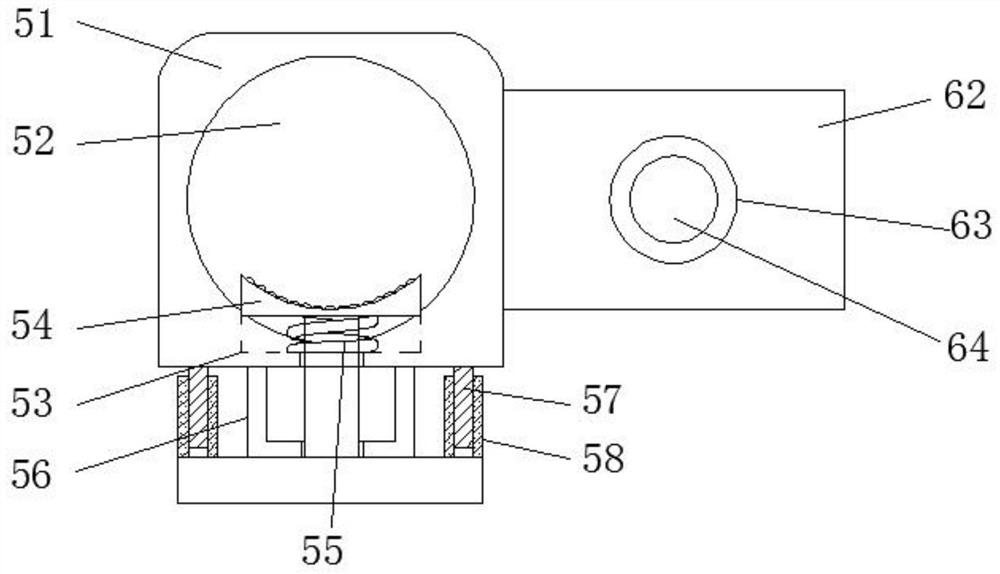

[0036] A method for processing a concrete prefabricated culvert, the processing method comprising the following steps:

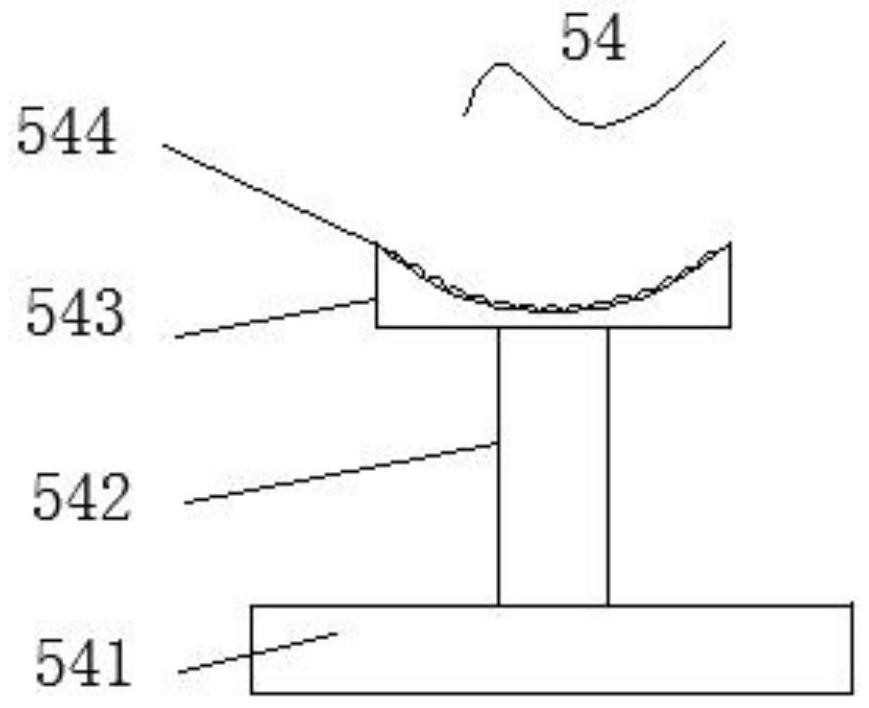

[0037] S1, the production of steel skeleton

[0038] According to the actual size of the inner diameter of the ring bar of the steel bar skeleton to be produced, the horizontal steel bars are circularly distributed in the seam welding machine, and the limiter is used to limit the ends of the horizontal steel bars. The seam welding machine welds the longitudinal steel bars to the outer surface of the horizontal steel bars to obtain Steel skeleton;

[0039] S2, mold assembly

[0040] Brush clean engine o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com