Application of MOF separation material in N2/O2 separation

A separation material and molecular formula technology, applied in the application field of MOF separation material in N2/O2 separation, can solve the problem of large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

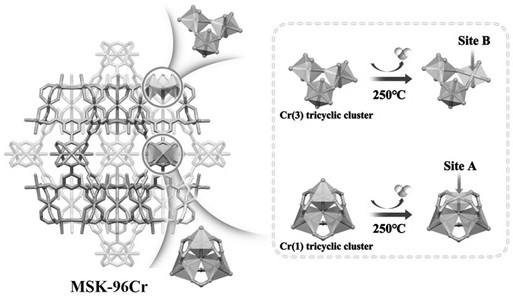

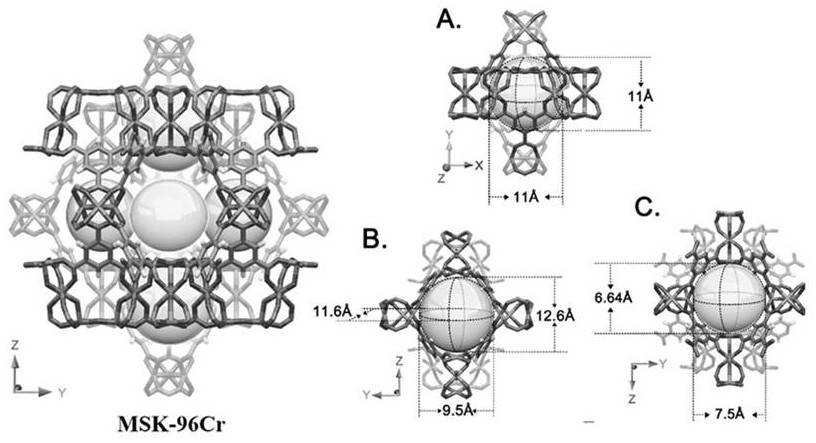

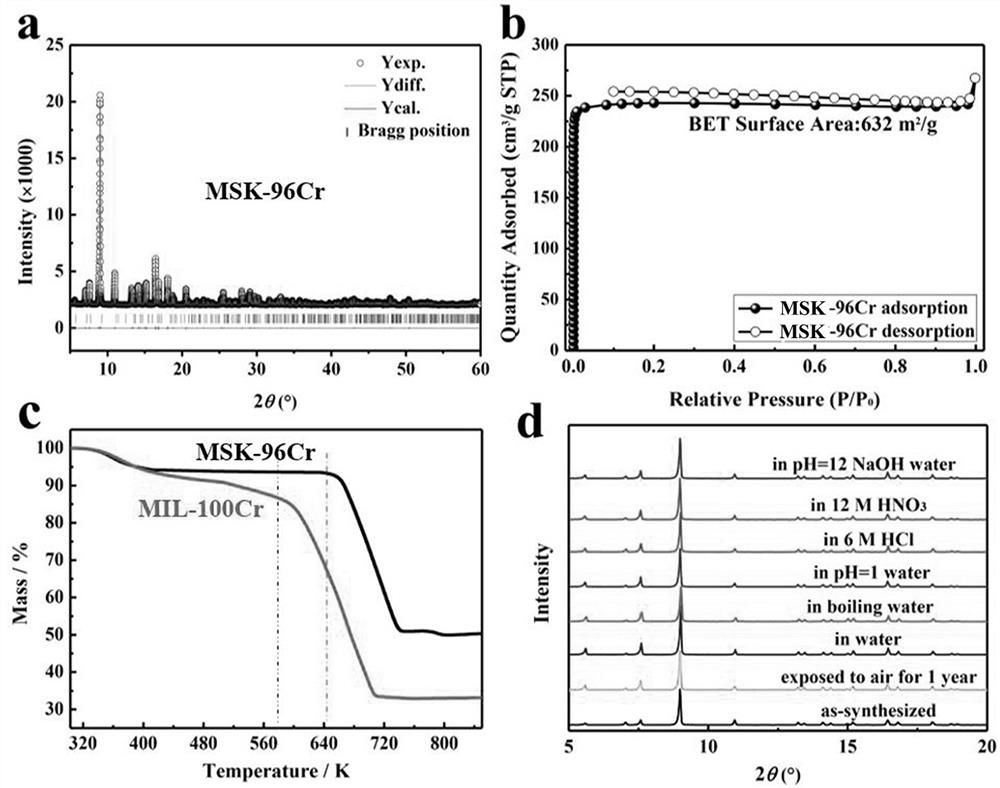

[0033] MSK-96Cr preparation:

[0034] Metallic chromium powder (104 mg, 2 mmol) and H3BTC (280 mg, 1.34 mmol) were added to a 50 mL polytetrafluoroethylene reactor, and then, 10 mL of methanol / water mixed solution (1:1, v / v ) and 0.8 mL of hydrofluoric acid (4 mmol)) were added to the reaction kettle using a pipette. The above mixture was stirred at 298 K for 0.5 h. After the stirring was completed, the polytetrafluoroethylene reactor was sealed in a stainless steel shell and placed in an oven. The temperature of the oven was raised from room temperature to 483 K within 12 h, and kept at 483 K for 96 h, and then the reactor was taken out to cool down to room temperature naturally. The light green product obtained by the reaction was first filtered, and then washed three times with distilled water and methanol at a ratio of 1 g product / 250 mL distilled water and 1 g product / 250 mL methanol at 353 K to remove excess unreacted organic compounds. body. The resulting MSK-96Cr pr...

Embodiment 2

[0043] Example 2 N at different pressures 2 Adsorption capacity

[0044] Different adsorbent materials MIL-100Cr, ZIF-8, UIO-66, Co-MOF-74, Cu-BTC, MIL-101Cr, 13X, Li-LSX and MSK-96Cr materials were mixed at 298 K with a gas flow rate of 15ml / min, N 2 Different N with partial pressure of 0.1 bar, 0.5 bar, 0.79 bar, 1 bar 2 / O 2 Mixed gas to N 2 For the comparison of separation capacity, the equipment used for gas adsorption is the same as that of Example 1.

[0045] according to Figure 4 The results shown, combined with the respective adsorption materials for N 2 It can be seen from the adsorption situation that MSK-96Cr exhibits the highest N 2 Adsorption capacity, N at 1 bar 2 The adsorption capacity can reach 37.46 cm 3 •cm -3 , the adsorption capacity is remarkable.

Embodiment 3

[0046] Example 3 Adsorption selectivity Different adsorption materials MIL-100Cr, ZIF-8, UIO-66, Co-MOF-74, Cu-BTC, MIL-101Cr, 13X, Li-LSX and MSK-96Cr were used for the above samples Carry out gas adsorption experiment, the equipment used of gas adsorption is the same as embodiment 1.

[0047] At 298K and 1 bar, N 2 N at partial pressures of 0.01 bar, 0.1 bar, 0.50 bar and 0.79 bar 2 / O 2 (total pressure is 1bar) mixed gas to N 2 Selective results such as Figure 5 and Table 1.

[0048] Table 1 N of different adsorbents 2 / O 2 selectivity

[0049]

[0050]

[0051] The results show that MSK-96Cr has better adsorption selectivity than other adsorbent materials under several partial pressure conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com