Preparation method of milky instant fat powder for feed

A fat powder, instant technology, applied in the application, animal feed, animal feed and other directions, can solve the problems affecting the nutritional value and palatability of feed, animal healthy growth and production hazards, insufficient anti-business factor effect, etc., to achieve good palatability. , good growth-promoting performance, improved fermentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

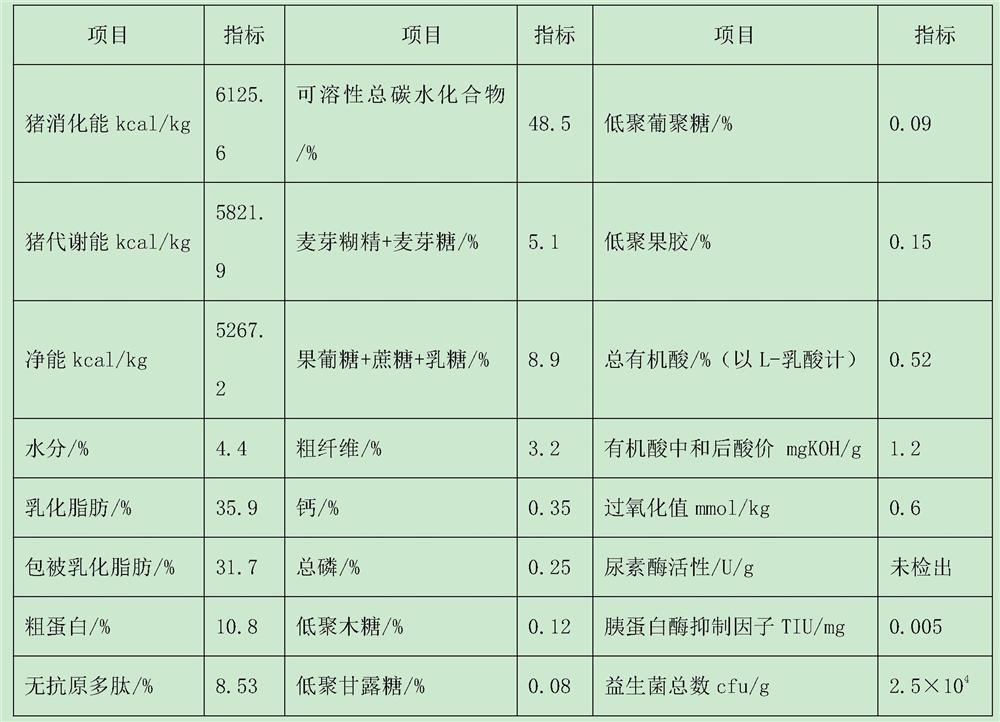

Embodiment 1

[0026] A preparation method for milky instant fat powder for feeding, comprising the following steps:

[0027] (1) Remove impurities and dust from 15kg of broken rice, 15kg of corn, 15kg of soybean meal and 5kg of peeled peanuts, first coarsely pulverize and then superfinely pulverize to 350 mesh, and obtain 15kg of superfine pulverized rice, 15kg of superfine corn and 15kg of superfine powder Soybean meal and 5kg superfine powdered peanuts.

[0028] (2) Add 15kg of superfine ground rice, 15kg of superfine corn, 15kg of superfine soybean meal and 5kg of superfine peanut to the twin-screw extruder for 2 minutes under the conditions of pressure 4Mpa and temperature 140°C. 15.7kg of expanded superfine pulverized rice, 15.7kg of expanded superfine corn, 15.7kg of expanded superfine soybean meal and 5.2kg of expanded superfine peanut were prepared.

[0029] (3) Send 15.7kg of extruded superfine pulverized rice, 15.7kg of extruded superfine corn, 15.7kg of extruded superfine soybea...

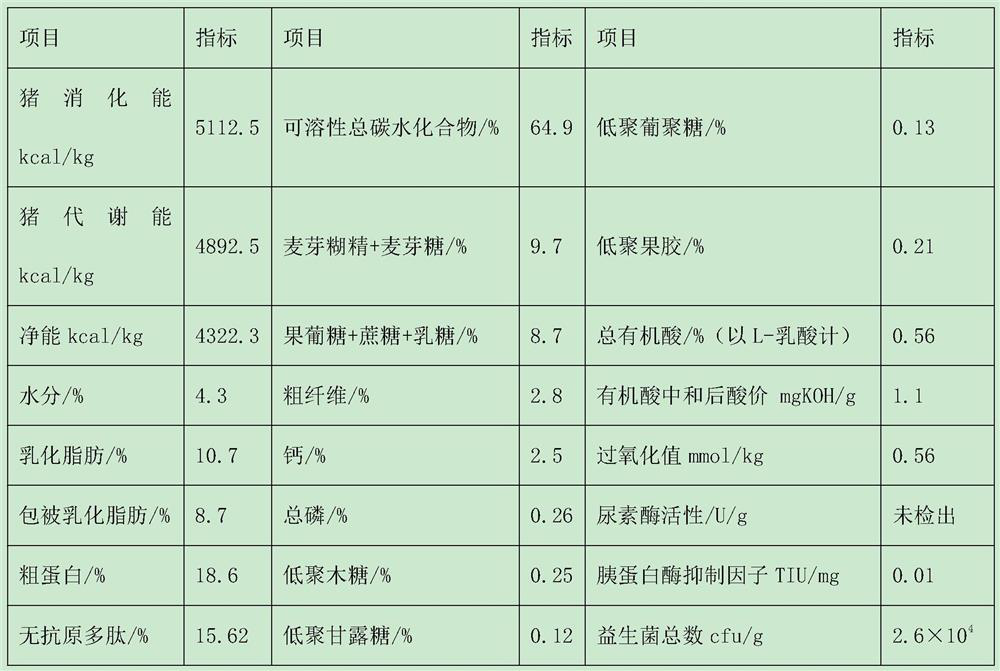

Embodiment 2

[0034] A preparation method for milky instant fat powder for feeding, comprising the following steps:

[0035] (1) Remove impurities and dust from 24kg of broken rice, 24kg of corn, 24kg of soybean meal and 8kg of peeled peanuts, first coarsely pulverize and then superfinely pulverize to 400 mesh, and obtain 24kg of superfine pulverized rice, 24kg of superfine corn and 24kg of superfine powder Soybean meal and 8kg superfine powdered peanuts.

[0036] (2) Add 24kg of superfine ground rice, 24kg of superfine corn, 24kg of superfine soybean meal and 8.3kg of superfine peanut to the twin-screw extruder for 2 minutes under the conditions of pressure 4Mpa and temperature 140°C. Under the conditions, 25kg of extruded superfine pulverized rice, 25kg of extruded superfine corn, 25kg of extruded superfine soybean meal and 8.3kg of extruded superfine peanut were prepared.

[0037] (3) Send 25kg of extruded superfine crushed rice, 25kg of extruded superfine corn, 25kg of extruded superfi...

Embodiment 3

[0042] A preparation method for milky instant fat powder for feeding, comprising the following steps:

[0043] (1) 150 kg of broken rice, 150 kg of corn and 180 kg of soybean meal were removed from impurities and dust respectively, first coarsely pulverized and then ultrafinely pulverized to 200 mesh, and superfinely pulverized rice, superfine corn and superfine soybean meal were obtained.

[0044] (2) Add 150kg of ultra-fine ground rice, 150 kg of ultra-fine corn and 180 kg of ultra-fine soybean meal to the twin-screw extruder for conditioning and tempering respectively, and then puff and ripen them for 5 minutes under the conditions of pressure 3Mpa and temperature 130°C to obtain puffed ultra-fine ground rice 157kg, 157kg of extruded superfine corn and 187kg of extruded superfine soybean meal.

[0045] (3) Send 157kg of extruded ultra-fine powdered rice, 15.kg of extruded ultra-fine powdered corn and 187 kg of extruded ultra-fine powdered soybean meal into the roasting and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com