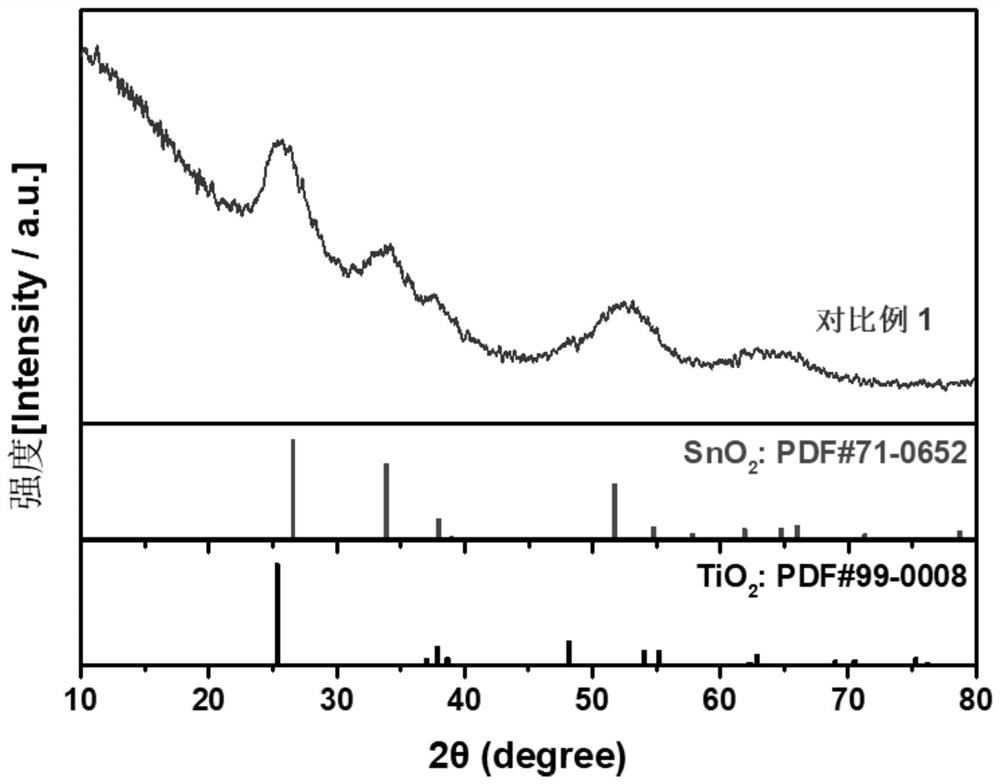

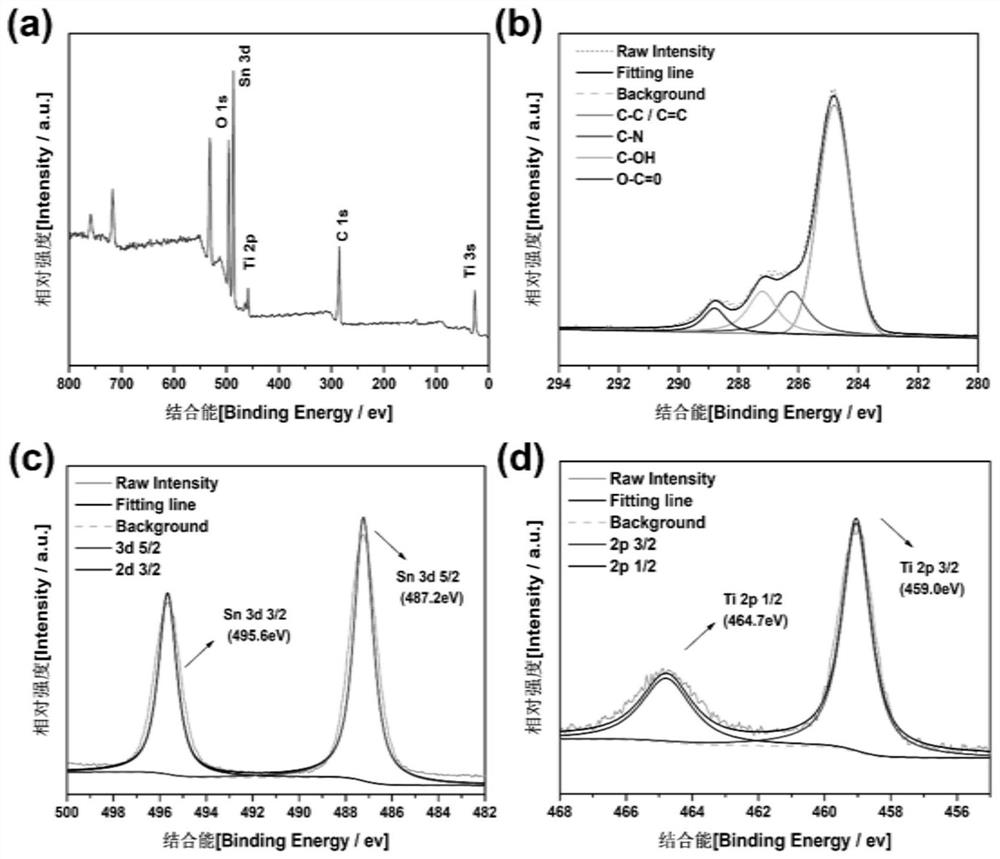

Preparation method and application of SnO2-TiO2@rGO lithium ion battery negative electrode material

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as poor cycle performance, and achieve the effects of preventing agglomeration, good rate and cycle performance, and excellent specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) The freeze-dried graphene oxide (GO) was pulverized in a planetary ball mill at a speed of 40r / s for 6h, and then 0.1g of graphene oxide powder samples were taken and uniformly dispersed in 20ml of 1-allyl-3 - Methylimidazolium chloride organic solvent, stirred at 300rpm magnetic stirring speed for 12h, and ultrasonicated at 20KHz for 0.5h to obtain GO suspension.

[0034] (2) the composite metal source, 1.70g of SnCl 4 and 0.43g of TiCl 4 Slowly add the liquid into the GO suspension in a fume hood, and under the action of 300rpm magnetic stirring, wait until it is fully mixed, and react with water at 80°C for 10 hours to obtain a gray black suspension.

[0035] (3) Wash and centrifuge the above obtained sample 5 times, the centrifugal speed is gradually increased from 5000rpm to 7000rpm, the centrifugation time is gradually increased from 12 minutes to 15 minutes, then suction filtered once, and freeze-dried at a low temperature for 48 hours using a lyophilizer. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com