Hot line unit dry power calculation method and liquid water content calculation method based on hot line unit dry power calculation method

A technology of liquid water content and calculation method, applied in computer-aided design, calculation, material water content and other directions, can solve problems such as affecting measurement accuracy, difficult to fully establish core assumptions, defects, etc., and achieve the effect of overcoming low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

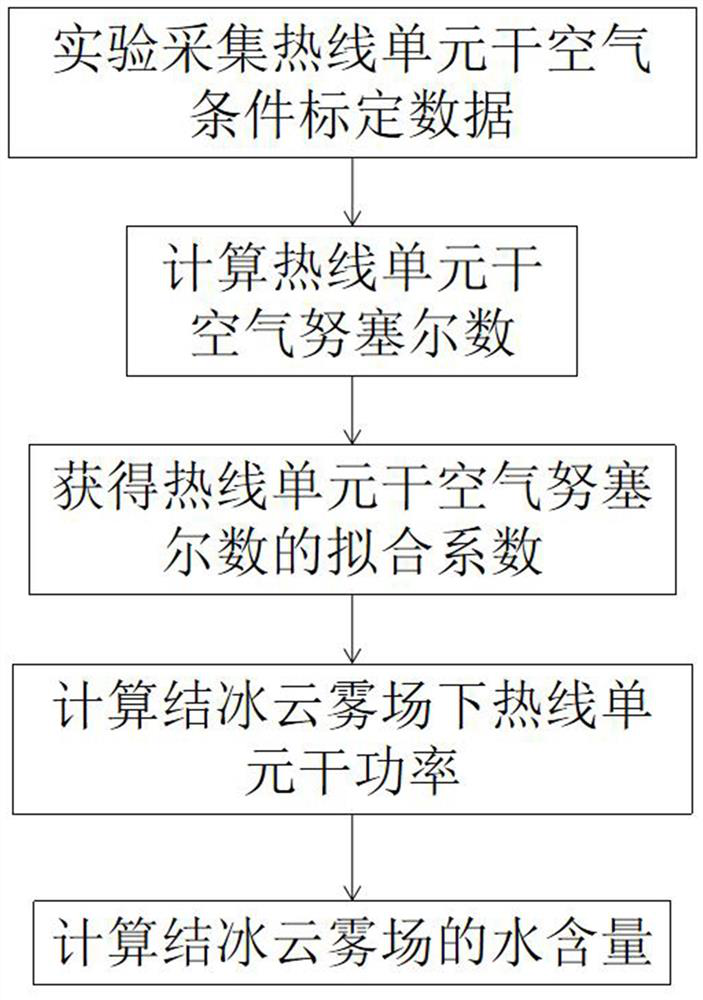

[0048] This embodiment 1 provides a method for calculating the dry power of a hot line unit, including the following steps:

[0049] S10. Experimental collection of hotline unit dry air calibration data

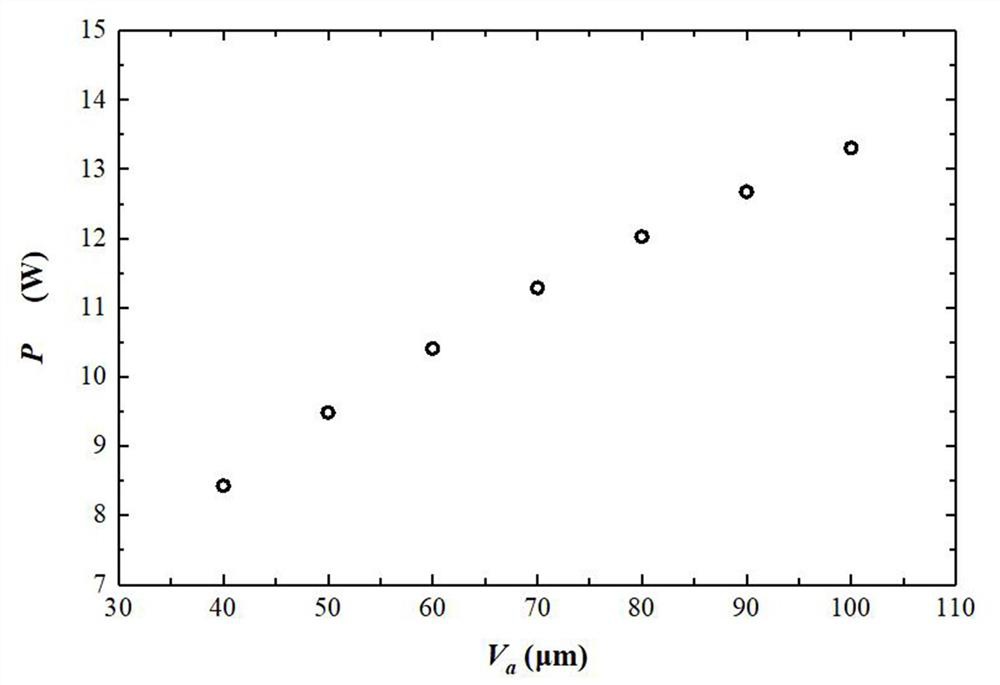

[0050] Collect the power P of the hot wire unit and the temperature T of the hot wire under different working conditions under dry air conditions w , air velocity V a , air static temperature T s ; Select typical test conditions in this embodiment: air velocity V a =40m / s, 50m / s, 60m / s, 70m / s, 80m / s, 90m / s, 100m / s, static air temperature T s =-3°C, air static pressure Ps=1atm. Among them, the collected power of the hot wire unit under each speed condition is as follows: figure 2shown.

[0051] It is worth noting that the dry air condition means that the dry air flow field only contains air and does not contain cloud particles.

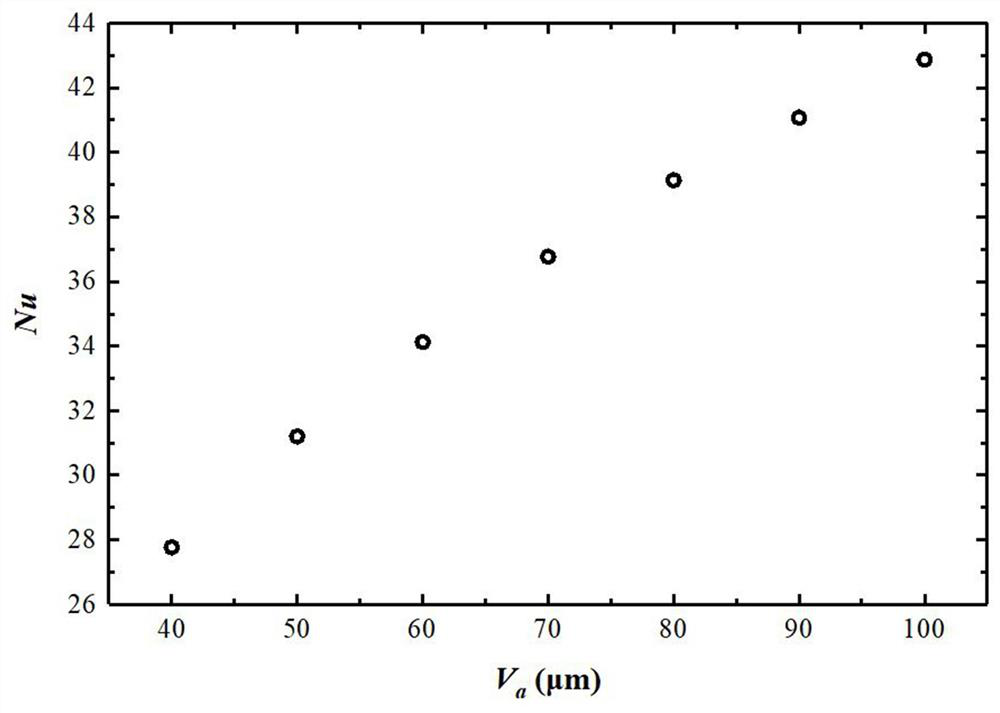

[0052] S20. Calculate the Nusselt number Nu of the hot line unit dry air:

[0053]

[0054] Among them, k is the heat transfer coefficien...

Embodiment 2

[0069] This embodiment provides a calculation method for liquid water content. During the cloud and fog test, the power of the hot wire unit P during the entire spraying process is collected. total , using the dry power calculated in Example 1 to calculate the liquid water content, such as figure 1 Shown:

[0070] The following formula is used to calculate the liquid water content LWC of icing clouds and fog:

[0071]

[0072] Among them, P total is the power of the hot wire unit measured in the cloud field, Ec is the liquid water droplet impact coefficient of the hot wire unit, Rc is the liquid water droplet evaporation ratio of the hot wire unit, Le is the latent heat of droplet evaporation, C l is the specific heat of liquid water, Te is the evaporation temperature of the droplet, and SV is the sampling volume of the hot wire unit;

[0073]

[0074] V a1 is the air velocity in the cloud field, d w is the diameter of the hot wire, and the calculation result of liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com