Heading machine and supporting shoe unit thereof

A technology for roadheaders and propulsion cylinders, which is applied in mining equipment, earthwork drilling, tunnels, etc. It can solve problems such as slow tunneling efficiency, inability to provide supporting force with support shoes, construction deviation, etc., and achieve the effect of reducing the overall occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

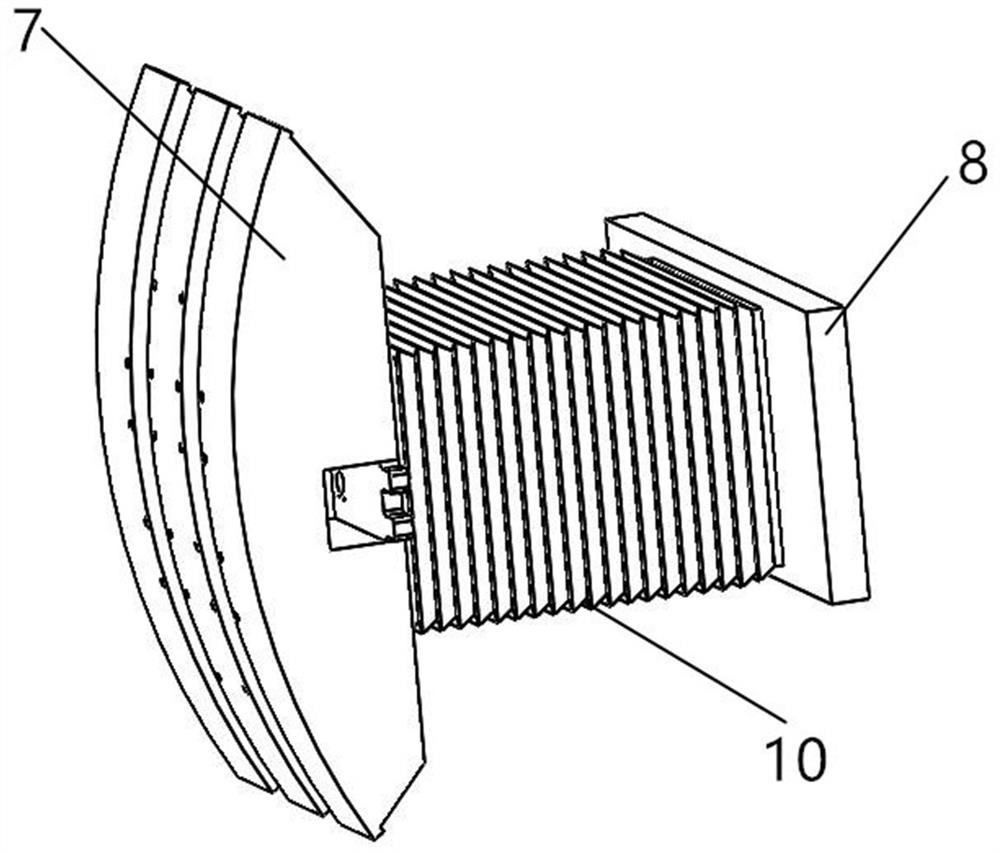

[0060] The shoe unit 3 configured on the roadheader provided in this embodiment uses superconducting electromagnets to provide magnetic repulsion, forcing the shoe 7 to support the tunnel wall. Compared with the way of hydraulic cylinder support, it can provide the same magnetic repulsion. Next, the shoe unit 3 using superconducting electromagnets is relatively small in size and occupies a relatively small space. In the case of the same size, the support shoe unit 3 using superconducting electromagnets can conveniently provide a sufficiently large supporting force to meet the need for supporting the roof of the roadheader under abnormal working conditions.

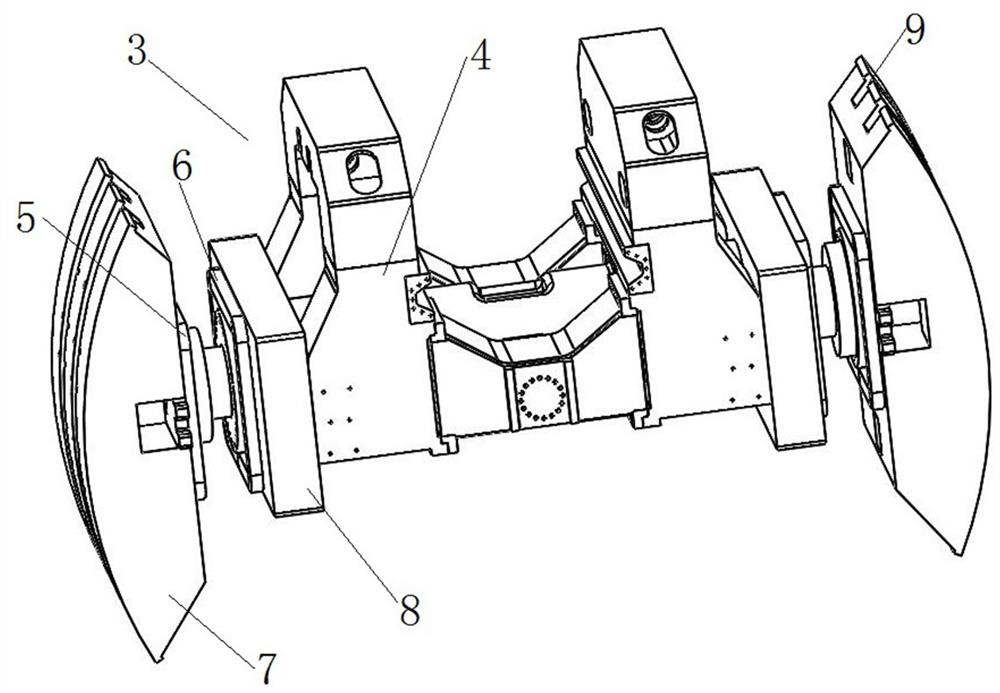

[0061] The structure of the boring machine provided by this embodiment is as follows: Figure 1 to Figure 4 As shown, it is specifically a shield machine. like figure 1 As shown, the shield machine includes a roadheader body 1, which extends along the front and back directions as a whole, and a cutterhead 2 is arranged a...

specific Embodiment 2

[0079] It differs from Embodiment 1 mainly in that: in Embodiment 1, the telescopic driving structure on each side includes a protruding driving structure and a retracting driving structure respectively. In this embodiment, each telescoping drive structure includes a protruding drive structure, and the protruding drive structure also includes an inner superconducting electromagnet and an outer superconducting electromagnet, which can be used to generate electricity. Magnetic repulsion, and then drives the corresponding side stand shoe to protrude outward. In addition, the current direction of the superconducting electromagnet on one side can be changed separately, and then the direction of the magnetic field can be changed, so that the inner superconducting electromagnet and the outer superconducting electromagnet are energized to generate magnetic attraction force, and the shoe is driven to slowly retract by slowly increasing the current flow.

[0080] It should be noted that...

specific Embodiment 3

[0082] The main difference between it and Embodiment 1 is that in Embodiment 1, the inner superconducting electromagnet in the telescopic drive structure on each side is fixedly assembled with the corresponding fixed mounting parts by means of bolt connection, and the outer superconducting electromagnet is also connected by bolts. The way is fixedly assembled with the corresponding boots. In this embodiment, the inner superconducting electromagnet can be fixedly assembled with the corresponding fixed installation part by welding, and the outer superconducting electromagnet can also be fixedly assembled with the corresponding support shoe by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com