Lifting type permanent magnet stirring device and method

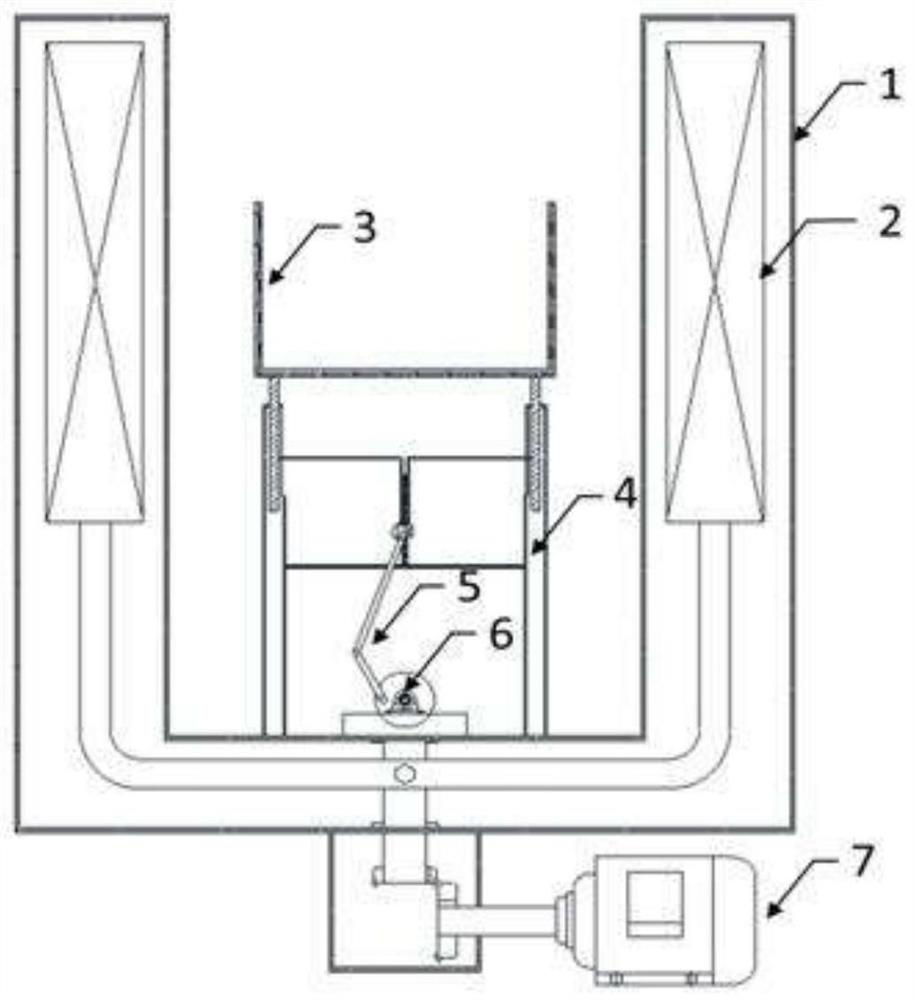

A permanent magnetic stirring and lifting technology, which is applied in the direction of mixer accessories, chemical instruments and methods, transportation and packaging, etc., can solve unfavorable melt solidification, structure and performance, unfavorable regulation and improvement of billet quality, single magnetic field mode, etc. problems, to achieve the effect of improving billet quality, reducing solute segregation, and realizing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Put the MgO crucible containing the sulfur-containing non-quenched and tempered steel melt on the tray, turn on the permanent magnetic stirring device, apply alternating permanent magnetic stirring to the melt, first rotate forward for 1 minute and then reverse for 1 minute, and reciprocate in this way. The stirring time is 10 minutes, the magnetic induction intensity is 2000Gs during the stirring process, and the magnet rotation speed is 200rpm. After the stirring was completed, the ingot was taken out and cooled with water to obtain a sample. The analysis and detection of MnS in the sample found that the average equivalent diameter is 3.8 μm, the main shape of MnS is spindle, short rod and ellipse, and there is no aggregation distribution phenomenon.

Embodiment 2

[0039] Put the MgO crucible containing the sulfur-containing non-quenched and tempered steel melt on the tray, turn on the permanent magnetic stirring device, apply alternating permanent magnetic stirring to the melt, first rotate forward for 2 minutes and then reverse for 2 minutes, and reciprocate in this way. The stirring time is 12min, the magnetic induction intensity is 1500Gs during the stirring process, and the magnet rotation speed is 150rpm. After the stirring was completed, the ingot was taken out and cooled with water to obtain a sample. The analysis and detection of MnS in the sample found that the average equivalent diameter is 4.2 μm, the main shape of MnS is spindle, short rod and ellipse, and there is no aggregation distribution phenomenon.

[0040] To sum up, the device and method of this application can easily realize multi-level and diversified control of the magnetic field at the position of the melt, such as magnetic field strength, magnetic field movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com