Control valve and mechanical linkage pressure switch valve

A technology for controlling valves and pressure, applied in mechanical equipment, diaphragm valves, safety valves, etc., can solve the problems of easy cracks or gaps in the diaphragm, fixed failure of the periphery of the diaphragm, deformation of the diaphragm, etc., to achieve good sealing effect, high pressure The effect of reducing and slowing down the degree of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

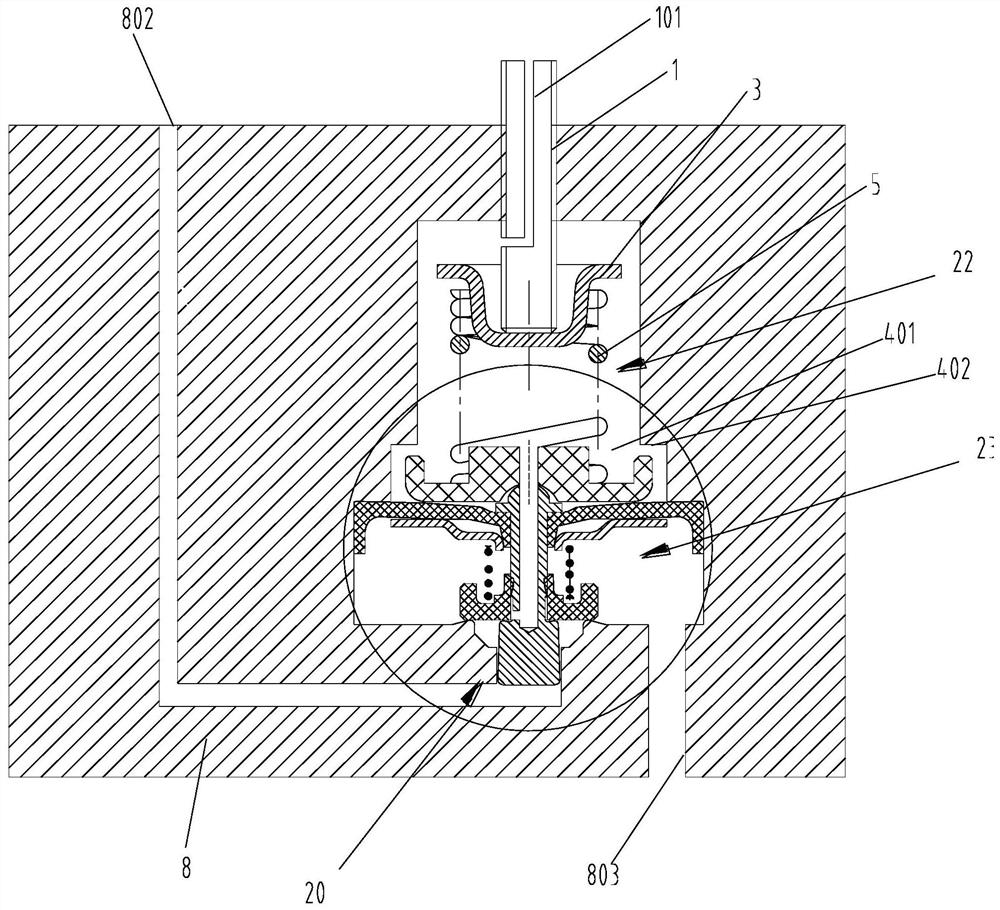

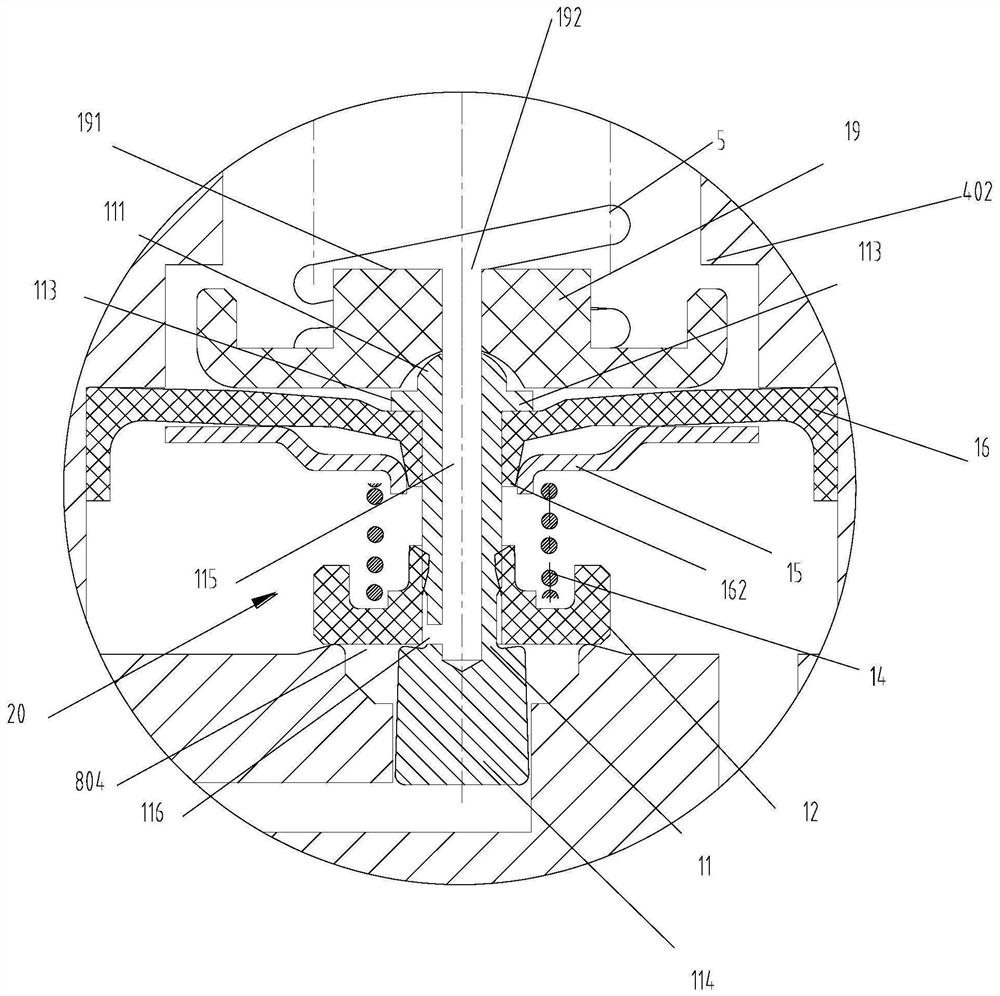

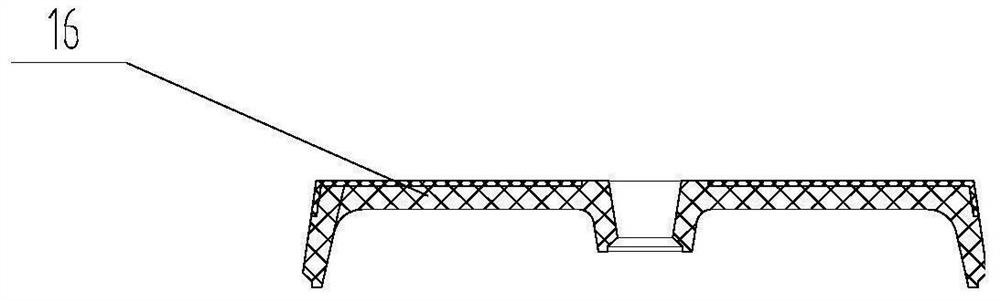

[0045] Such as Figure 1-3 As shown, a control valve includes a valve body 8, a cavity 401 is formed in the valve body 8, a fluid opening 804 is formed at the bottom of the cavity 401, and a valve stem assembly 20, an elastic sealing part 16 and an upper pressure assembly are arranged in the cavity 401 22. The elastic sealing part 16 is used to drive the valve stem assembly 20 to move so that the valve stem assembly 20 blocks or opens the fluid opening 804. The upper pressure assembly 22 is arranged in the cavity 401 above the elastic sealing part 16. The upper pressure assembly 22 is used to adjust The pressure exerted on the elastic sealing part 16 ; it also includes a downward pressure component 23 for buffering the deformation of the elastic sealing part 16 , which is arranged in the cavity 401 below the elastic sealing part 16 .

[0046] Further, in this embodiment, the lower pressure assembly 23 includes a compression spring 14, the compression spring 14 is a coil spring...

Embodiment 2

[0056] further reference Figure 4 , the present application also proposes a mechanical linkage pressure switch valve, which is a modification on the basis of Embodiment 1, the difference is as follows: it also includes a pressure sensor 7, the pressure sensor 7 is installed at the fluid outlet 802, and the pressure sensor 7 is based on The pressure of the fluid outlet 802 is switched off and a signal is output. Specifically, an accommodating chamber 811 is formed at the fluid outlet 802 , and the pressure sensor 7 is disposed in the accommodating chamber 811 .

[0057] Further, the pressure sensor 7 includes an elastically deformable switch diaphragm 701, a small spring 702, an electric contact 703, a terminal 704, and an inner valve body 705; Each side is provided with an electric contact piece 703, the bottom of the inner valve body 705 is connected with a switch diaphragm 701, and the top of the inner valve body 705 abuts against the small spring 702; 802 stretches out, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com