Deep peak regulation method for high-back-pressure unit

A high back pressure, unit technology, applied in mechanical equipment, steam engine installations, machines/engines, etc., can solve the problems of wind abandonment, peak regulation, ineffective power grids, etc., to improve the reheat steam pressure, reduce the possibility of water erosion, The effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

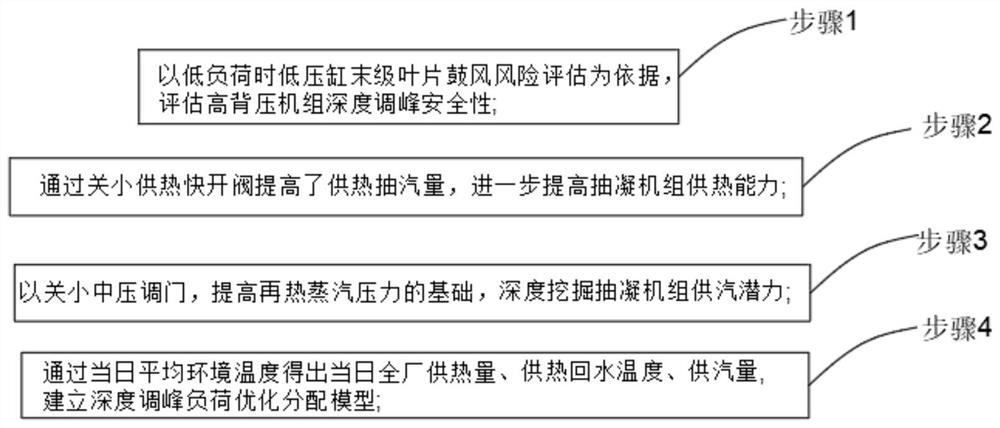

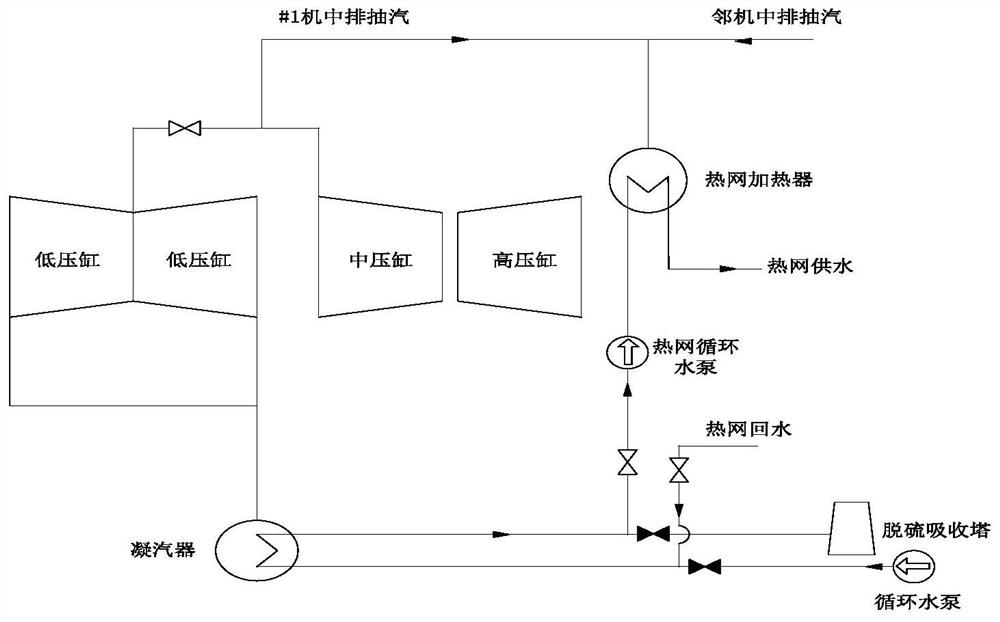

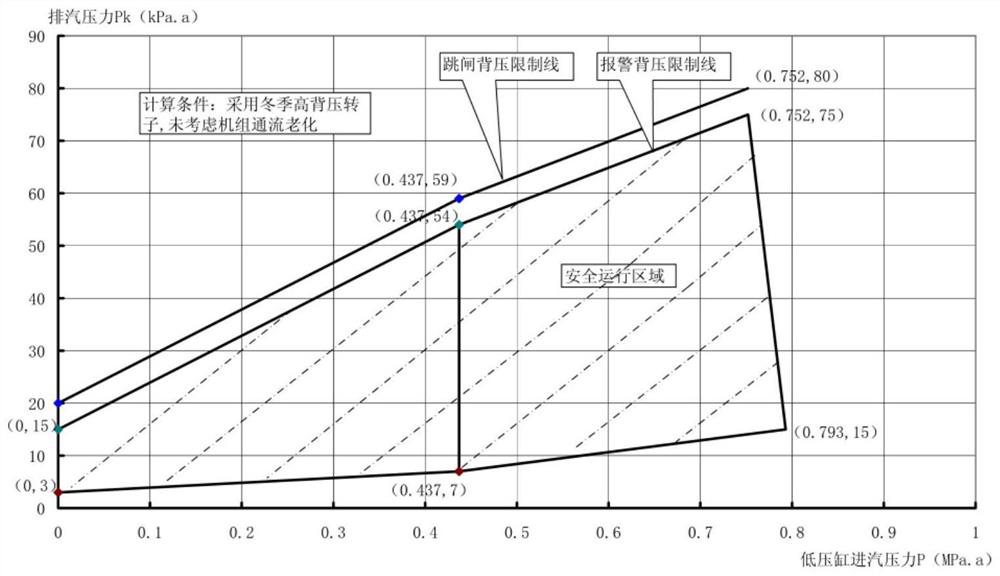

[0041] refer to Figure 1-3 , a deep peak regulation method for a high back pressure unit, comprising the following steps: evaluating the safety of deep peak regulation for a high back pressure unit based on the risk assessment of the final stage blade blowing of the low pressure cylinder at low load; The quick-opening valve increases the steam extraction capacity for heating and further improves the heat supply capacity of the condensing unit; by closing the small and medium-pressure valve, the basis for increasing the reheat steam pressure is deeply tapped for the steam supply potential of the condensing unit; the average ambient temperature of the day is used to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com