Pineapple leaf fiber reinforced flexible electromagnetic shielding film and preparation method thereof

A technology of pineapple leaf fiber and electromagnetic shielding film, applied in the direction of magnetic/electric field shielding, electrical components, etc., to achieve the effects of accelerating drying rate, improving mechanical strength, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

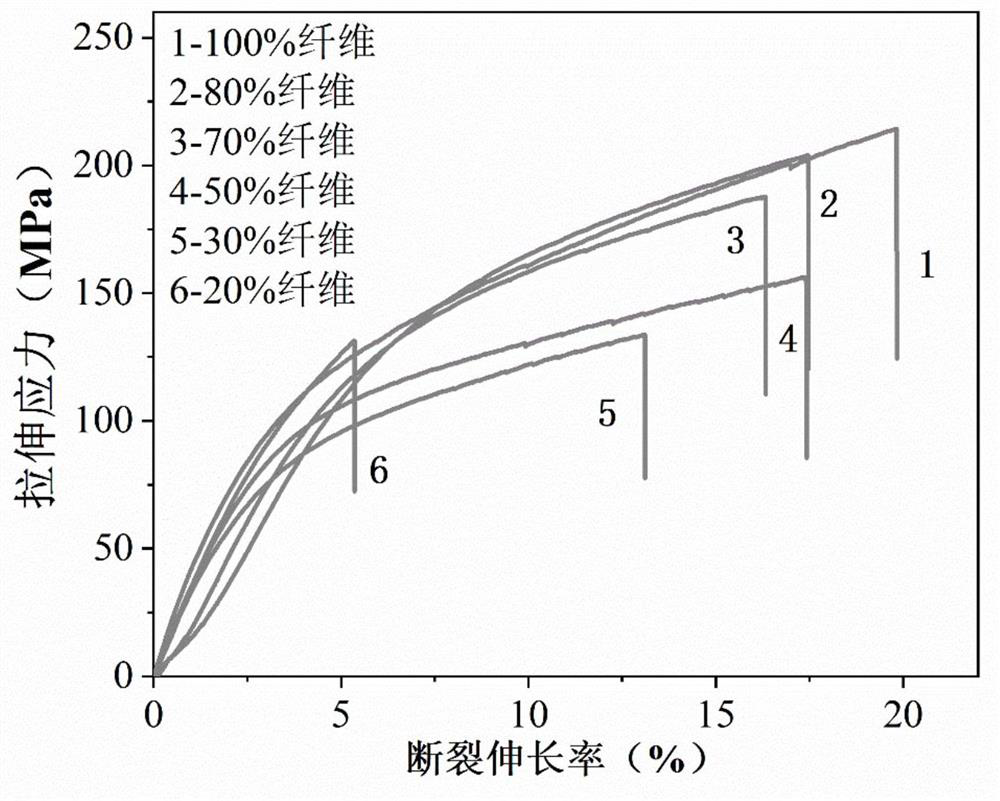

Embodiment 1

[0037] A kind of pure pineapple leaf nanofiber film and preparation method thereof, its preparation method comprises the steps:

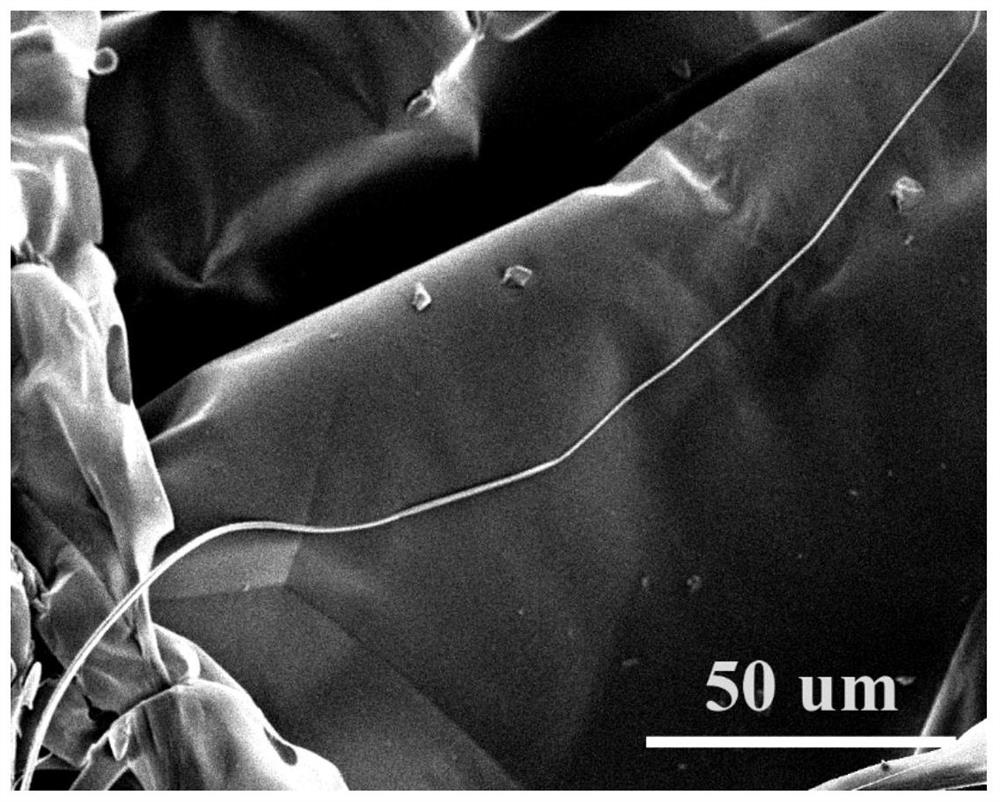

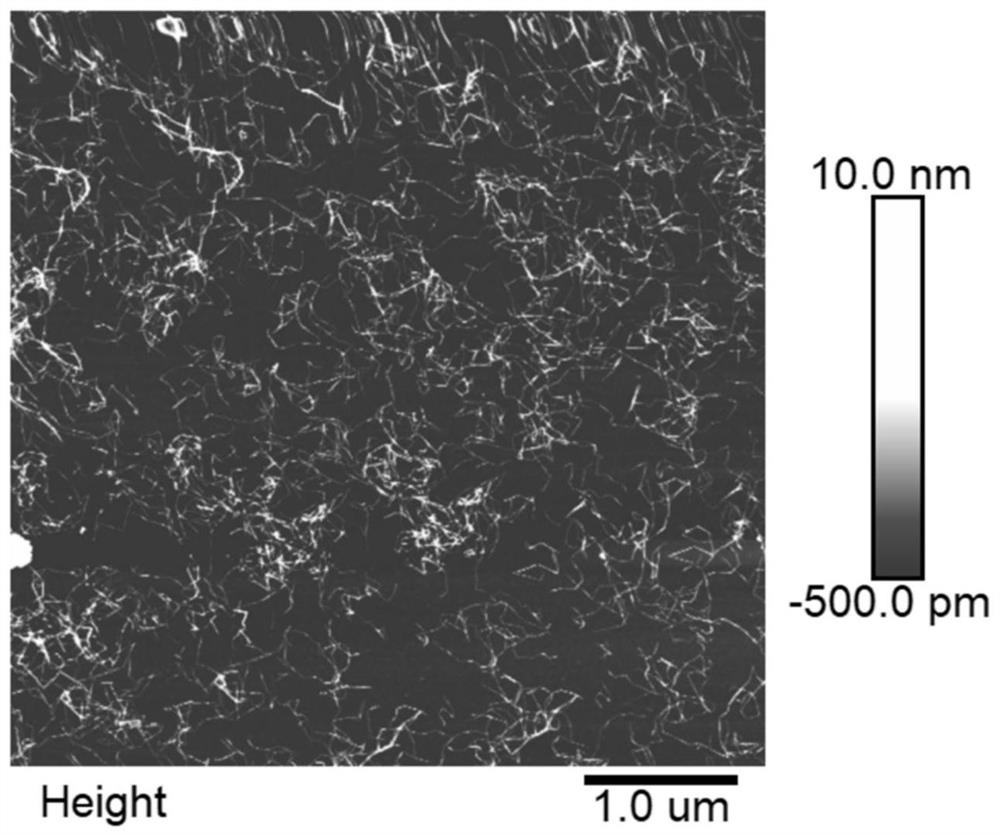

[0038] (1) Use short-cut pineapple leaf pieces with a length of 5 cm as raw materials, perform high-concentration deconcentration at a concentration of 15%, and then use a flat slotted sieve with a slot width of 0.35 mm to screen the pineapple leaf fibers separated from the mesophyll, and then use the Wali The beating machine carried out three-stage gradient low-consistency beating according to the concentration of 4%, so that the beating degree of pineapple leaf fiber was 40°SR. The obtained fiber adopts the carboxymethylation pretreatment method, disperses 10 g of dry fiber in 100 g of ethanol and soaks for 30 min, then weighs in a beaker according to 1.1 g of sodium chloroacetate corresponding to 1 g of dry fiber, and press 1: Add an equal amount of water to dissolve sodium chloroacetate at a mass ratio of 1, then weigh sodium hydroxide according...

Embodiment 2

[0042] A flexible electromagnetic shielding film reinforced by pineapple leaf fibers and a preparation method thereof, the preparation method comprising the steps of:

[0043] (1) Using short-cut pineapple leaf pieces with a length of 5 cm as raw materials, perform high-concentration deconcentration at a concentration of 20%, and then use a flat slotted sieve with a slot width of 0.15 mm to screen the pineapple leaf fibers separated from the mesophyll, and then use the Wali The beating machine performs three-stage gradient low-consistency beating according to the concentration of 8%, so that the beating degree of the pineapple leaf fiber is 55°SR. The obtained fiber adopts the carboxymethylation pretreatment method, disperses 10 g of dry fiber in 200 g of ethanol and soaks for 15 min, then weighs 0.9 g of sodium chloroacetate in a beaker according to 1 g of dry fiber, and press 1: Add an equal amount of water to dissolve sodium chloroacetate at a mass ratio of 1, then weigh so...

Embodiment 3

[0048] A flexible electromagnetic shielding film reinforced by pineapple leaf fibers and a preparation method thereof, the preparation method comprising the steps of:

[0049] (1) Use short-cut pineapple leaf pieces with a length of 5 cm as raw materials, perform high-concentration deconcentration at a concentration of 25%, and then use a flat slotted sieve with a slot width of 0.5 mm to screen the pineapple leaf fibers separated from the mesophyll, and then use the Wali The beating machine performs three-level gradient low-consistency beating according to the concentration of 4%, so that the beating degree of pineapple leaf fiber is 65°SR. The obtained fiber adopts the carboxymethylation pretreatment method, disperses 10 g of dry fiber in 200 g of ethanol and soaks for 15 min, then weighs in a beaker according to 1.1 g of sodium chloroacetate corresponding to 1 g of dry fiber, and press 1: Add an equal amount of water to dissolve sodium chloroacetate at a mass ratio of 1, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com