A circuit board and manufacturing process of a transparent LED display

A technology of LED display screen and manufacturing process, which is applied in the direction of printed circuit, printed circuit, circuit heating device, etc., can solve the problems of ineffective heat dissipation, waterproof, short circuit, circuit board damage, etc., and achieves improved processing performance and is not easy Excellent effect on damage, heat dissipation and waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

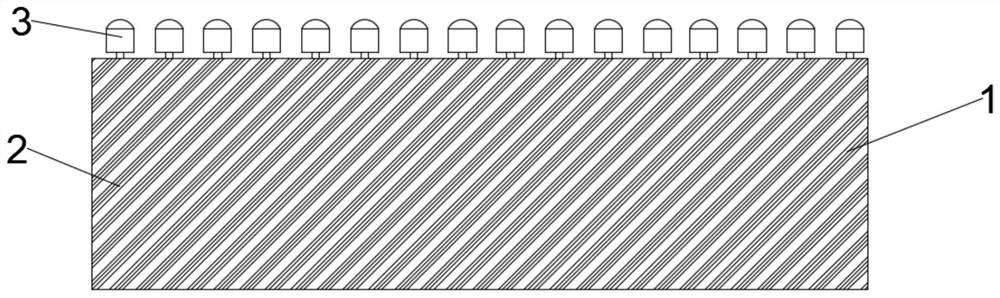

[0041] A circuit board 1 of a transparent LED display, such as Figure 1~2 As shown, it includes a PCB board 2 and an LED lamp bead 3 arranged on one side of the PCB board 2; the PCB board 2 includes a substrate 4, wherein both sides of the substrate 4 are sequentially provided with a prepreg 5 and an etched copper clad laminate 6, The material of the substrate 4 is polyimide, the thickness of the prepreg 5 is 0.1 mm, the thickness of the substrate 4 is 0.3 mm, and the thickness of the etched copper clad laminate 6 is 0.2 mm; the surface of the PCB board 2 is coated with an insulating heat dissipation layer 7.

[0042] The LED lamp bead 3 includes one or more of white light bead, yellow light bead, blue light bead and red light bead.

[0043] The insulating and heat-dissipating layer 7 is prepared from modified polyimide, which is prepared by mixing polyimide resin and modifier in dimethylformamide, and then vacuum drying; wherein , the mass ratio of polyimide resin, modifie...

Embodiment 2

[0057] A circuit board 1 of a transparent LED display, such as Figure 1~2 As shown, it includes a PCB board 2 and an LED lamp bead 3 arranged on one side of the PCB board 2; the PCB board 2 includes a substrate 4, wherein both sides of the substrate 4 are sequentially provided with a prepreg 5 and an etched copper clad laminate 6, The material of the substrate 4 is polyimide, the thickness of the prepreg 5 is 0.1 mm, the thickness of the substrate 4 is 0.3 mm, and the thickness of the etched copper clad laminate 6 is 0.2 mm; the surface of the PCB board 2 is coated with an insulating heat dissipation layer 7.

[0058] The LED lamp bead 3 includes one or more of white light bead, yellow light bead, blue light bead and red light bead.

[0059] The insulating and heat-dissipating layer 7 is prepared from modified polyimide, which is prepared by mixing polyimide resin and modifier in dimethylformamide, and then vacuum drying; wherein , the mass ratio of polyimide resin, modifie...

Embodiment 3

[0073] A circuit board 1 of a transparent LED display, such as Figure 1~2 As shown, it includes a PCB board 2 and an LED lamp bead 3 arranged on one side of the PCB board 2; the PCB board 2 includes a substrate 4, wherein both sides of the substrate 4 are sequentially provided with a prepreg 5 and an etched copper clad laminate 6, The material of the substrate 4 is polyimide, the thickness of the prepreg 5 is 0.1 mm, the thickness of the substrate 4 is 0.3 mm, and the thickness of the etched copper clad laminate 6 is 0.2 mm; the surface of the PCB board 2 is coated with an insulating heat dissipation layer 7.

[0074] The LED lamp bead 3 includes one or more of white light bead, yellow light bead, blue light bead and red light bead.

[0075] The insulating and heat-dissipating layer 7 is prepared from modified polyimide, which is prepared by mixing polyimide resin and modifier in dimethylformamide, and then vacuum drying; wherein , the mass ratio of polyimide resin, modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com