Cylindrical battery cell adopting non-welding conductive connection and preparation method thereof

A conductive connection, non-welding technology, applied in the field of cylindrical cells and their preparation, can solve the problems of limited space for welding area, poor welding head, long welding time affecting takt time, etc., to reduce equipment procurement and maintenance costs, The effect of improving cell safety performance and reducing procurement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

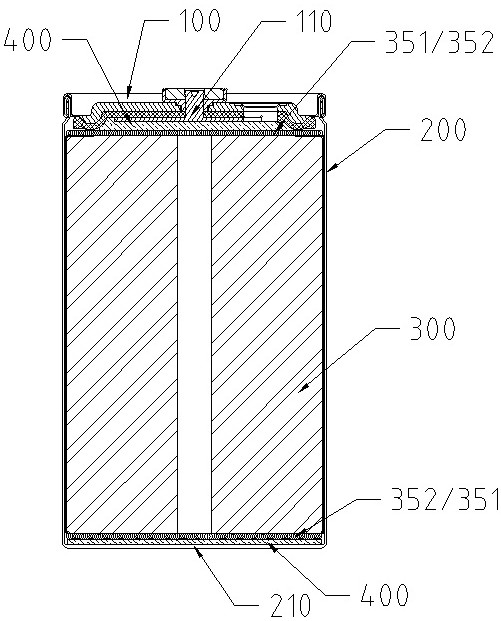

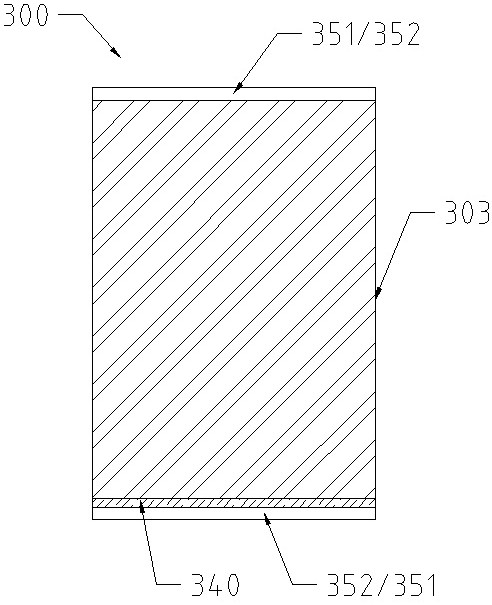

[0036] Such as Figure 1-2 As shown, a cylindrical electric core adopting non-welding conductive connection, which includes a cover 100, a casing 200, a winding core 300 and a conductive glue 400, and the winding core 300 contained in the casing 200 is composed of a negative electrode sheet 301, The positive electrode sheet 303, the first separator 302 and the second separator 304 are wound, and the negative electrode sheet 301 leaks outside the adjacent separator. The fluid 352 is electrically connected to the adjacent housing bottom 210 through the conductive glue 400. The positive electrode sheet 303 leaks to the adjacent separator. 351 is electrically connected to the adjacent pole contact surface 110 through the conductive glue 400 .

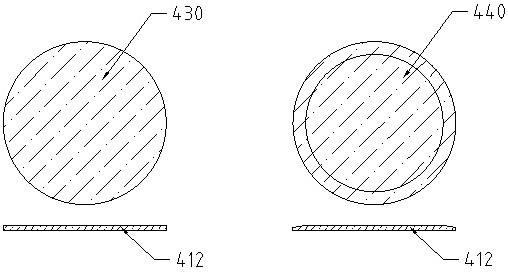

[0037] For a better effect, the conductive glue 400 connected to the bottom of the housing 210 is the shell bottom conductive glue 430, the conductive glue 400 connected to the pole contact surface 110 is the pole conductive glue 440, and ...

Embodiment 2

[0052] Such as Figure 1-2 As shown, a cylindrical electric core adopting non-welding conductive connection, which includes a cover 100, a casing 200, a winding core 300 and a conductive glue 400, and the winding core 300 contained in the casing 200 is composed of a negative electrode sheet 301, The positive electrode sheet 303, the first separator 302 and the second separator 304 are wound, and the negative electrode sheet 301 leaks outside the adjacent separator. The fluid 352 is electrically connected to the pole contact surface 110 of the adjacent upper cover 100 through the conductive glue 400, and the positive electrode leakage current collector 351 of the positive electrode sheet 303 leaking from the adjacent diaphragm is located at the other end of the winding core 300. The positive electrode drain current collector 351 is electrically connected to the adjacent casing bottom 210 through the conductive glue 400 .

[0053] For a better effect, the conductive glue 400 co...

Embodiment 3

[0067] Such as Figure 1-2 As shown, a cylindrical electric core adopting non-welding conductive connection, which includes a cover 100, a casing 200, a winding core 300 and a conductive glue 400, and the winding core 300 contained in the casing 200 is composed of a negative electrode sheet 301, The positive electrode sheet 303, the first separator 302 and the second separator 304 are wound, and the negative electrode sheet 301 leaks outside the adjacent separator. The fluid 352 is electrically connected to the pole contact surface 110 of the adjacent upper cover 100 through the conductive glue 400, and the positive electrode leakage current collector 351 of the positive electrode sheet 303 leaking from the adjacent diaphragm is located at the other end of the winding core 300. The positive electrode drain current collector 351 is electrically connected to the adjacent casing bottom 210 through the conductive glue 400 .

[0068] For a better effect, the conductive glue 400 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com