Mesh belt type sintering furnace

A sintering furnace, mesh belt technology, applied in the direction of furnace, furnace door, furnace type, etc., can solve the problem of reduced quality of parts, and achieve the effect of improving quality, increasing transmission ratio, and stabilizing furnace temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

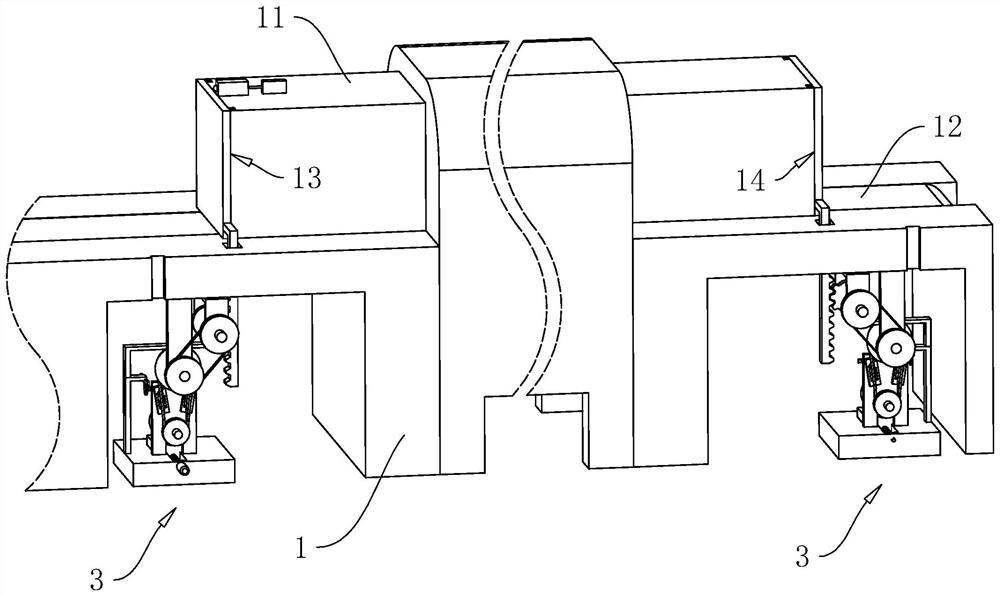

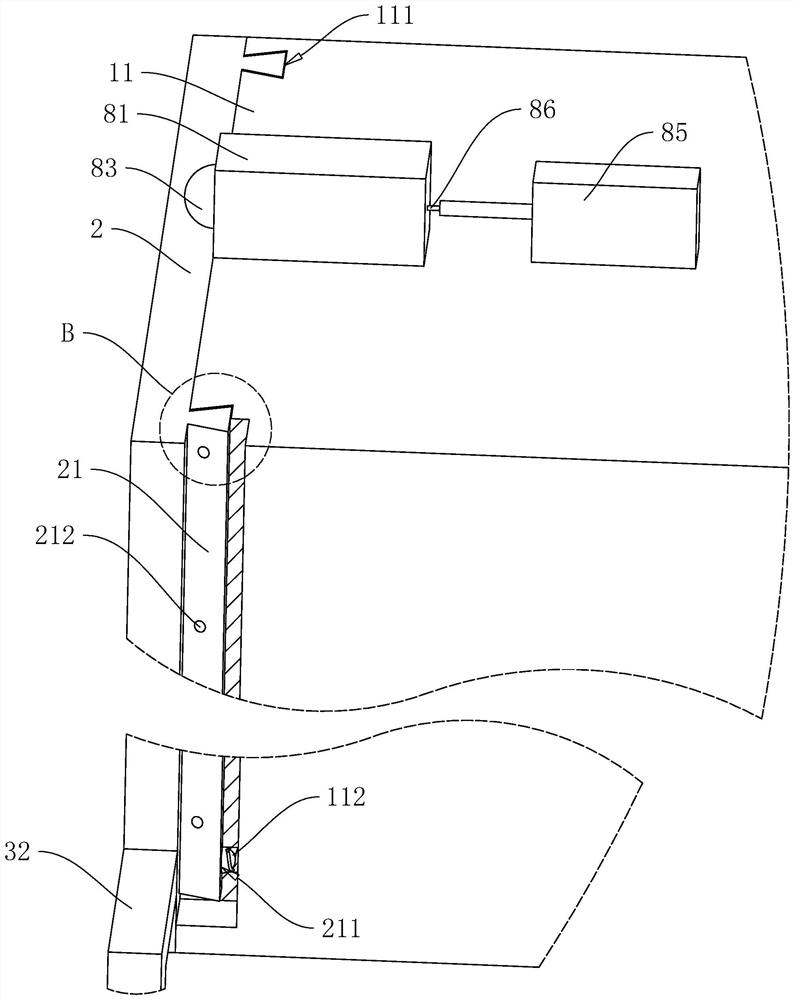

[0041] The following is attached Figure 1-7 The application is described in further detail.

[0042] The embodiment of the present application discloses a mesh belt type sintering furnace, referring to figure 1 , including a frame 1 placed on the ground, a cuboid furnace body 11 is fixedly installed on the frame 1, the furnace body 11 is provided with a furnace cavity, and the powdered metallurgical materials filled in the mold are sintered and formed in the furnace cavity . On the frame 1, a conveyor belt 12 is installed for rotation, and the two ends of the furnace body 11 are provided with a feed port 13 and a discharge port 14, and the feed port 13 and the discharge port 14 are all communicated with the furnace chamber of the furnace body 11, and the conveyor belt 12 It passes through the furnace cavity of the furnace body 11 along the feed port 13 and the discharge port 14, and the conveyor belt 12 is made of a high temperature resistant mesh belt.

[0043] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com