System and method for deicing wind power blades

A technology of wind power blades and freezing points, applied in the field of wind power blade deicing systems, can solve problems such as difficulties, environmental secondary pollution, equipment failure maintenance, etc., achieve strong removal ability, save time, and reduce impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

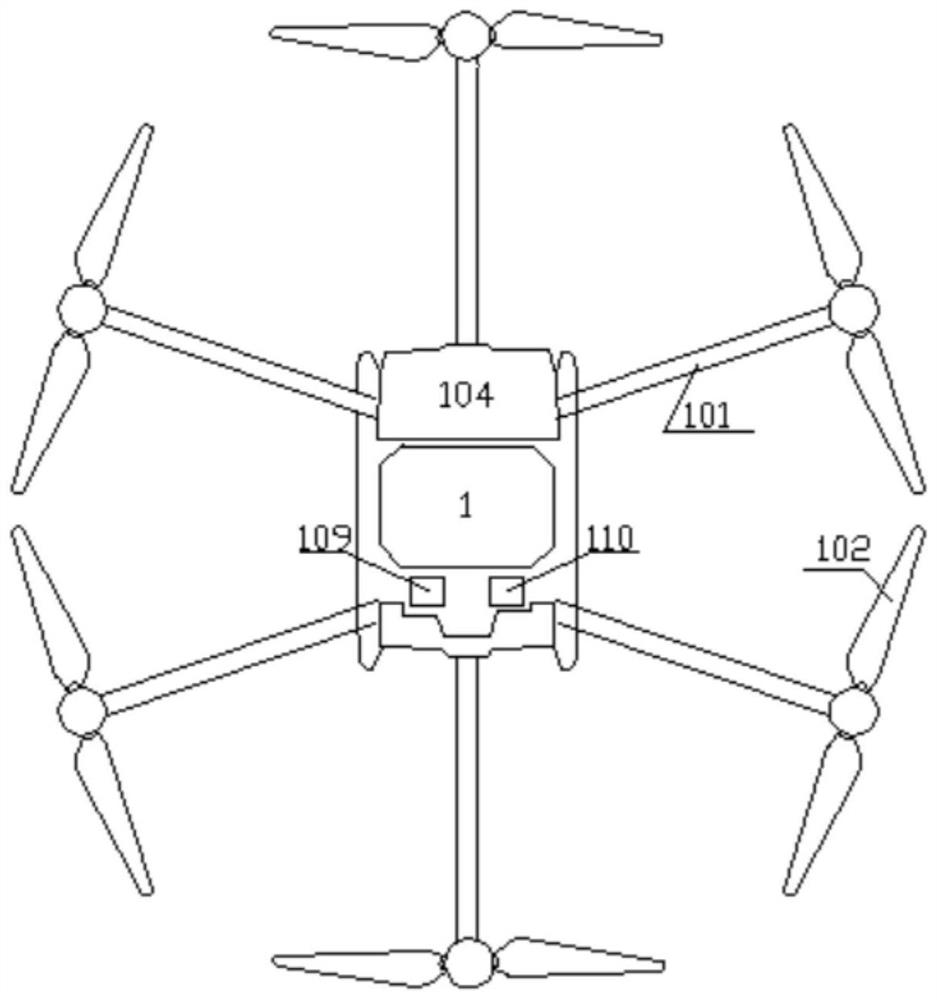

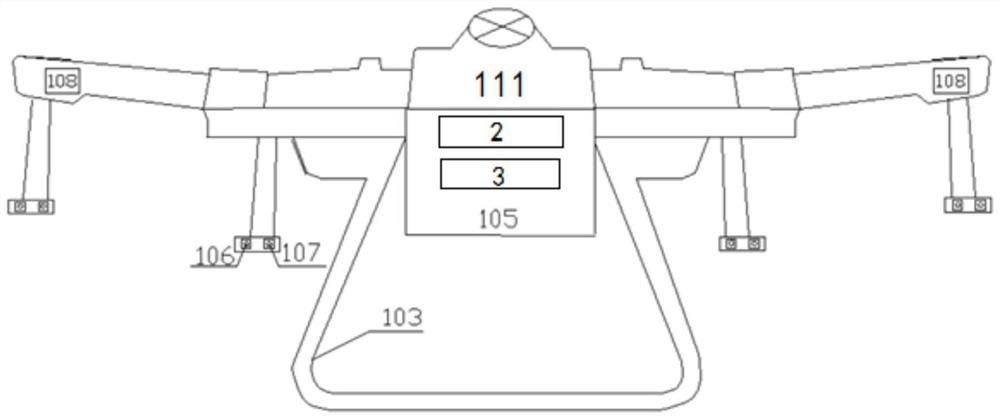

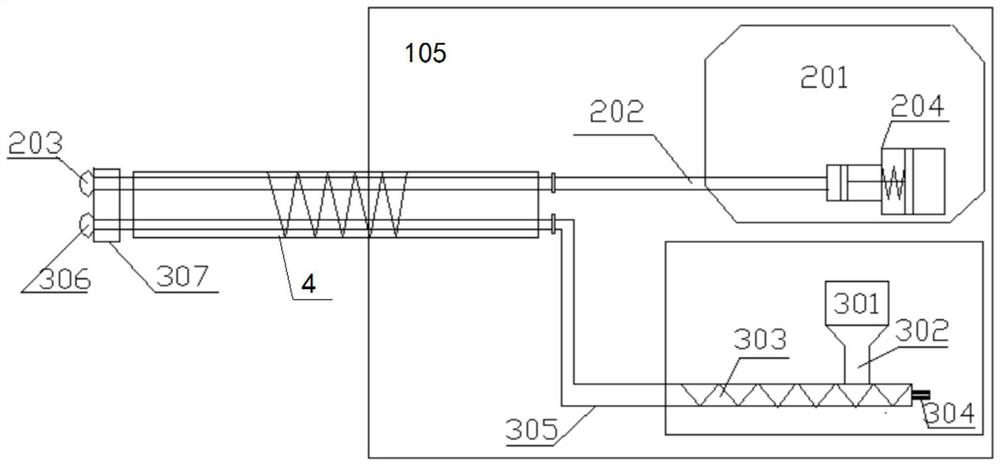

[0034] Such as figure 1 As shown, a system for deicing wind turbine blades includes a UAV body 1, a deicing cleaning device 2, an ice melting spray device 3 and an adjustable spray boom 4; wherein the UAV body includes a folding arm 101 , propeller 102, support frame 103, battery 104, lower support box 105, front and rear FPV camera 106, infrared camera 107, omnidirectional obstacle avoidance radar 108, positioning unit 109, flight control unit 110 and UAV main structure 111; deicing The cleaning device includes a cleaning liquid storage tank 201, an adjustable deicing cleaning agent pipeline 202 in the spray bar, a nozzle 203, and a plunger pump 204; the ice melting spray device includes a calcium oxide powder storage tank 301, a feeding funnel 302, and a screw transmission shaft 303, motor 304, calcium oxide powder pipeline 305, nozzle 306 and steering gear 307 in the adjustable spray bar.

[0035]Specifically, six folding arms 101 are connected to the main structure 111 of...

Embodiment 1

[0059] The UAV inspects the wind power blades. First, the UAV is lifted to the height of the blades. Through the UAV flight control unit 110, the UAV is hovered to a position 3 meters away from the wind power blades in the horizontal direction, and the infrared camera is turned on. 107 takes all-round shots of the wind power blades, and determines the freezing point of the wind power blades through the real-time images captured by the infrared camera. At this time, the real-time positioning unit 109 is turned on to record the coordinate information of the wind power blades' freezing points, and the drone is controlled to hover over the freezing points of the wind power blades. Near the freezing point, adjust the direction of the steering gear 307, align the powder atomizing nozzle 306 at the freezing point, start the ice-melting spray device 3, and first adjust the calcium oxide powder flow rate to 0.5kg / min on the control handle of the drone , and then turn on the motor, so th...

Embodiment 2

[0062] The UAV inspects the wind power blades. First, the UAV is lifted to the height of the blades. Through the UAV flight control unit 110, the UAV is hovered to a position 3 meters away from the wind power blades in the horizontal direction, and the infrared camera is turned on. 107 takes all-round shots of the wind power blades, and determines the freezing point of the wind power blades through the real-time images captured by the infrared camera. At this time, the real-time positioning unit 109 is turned on to record the coordinate information of the wind power blades' freezing points, and the drone is controlled to hover over the freezing points of the wind power blades. Near the freezing point, adjust the direction of the steering gear 307, align the powder atomizing nozzle 306 at the freezing point, start the ice-melting spray device 3, and first adjust the calcium oxide powder flow rate to 0.8kg / min on the control handle of the drone , and then turn on the motor, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com