Double-color slub colored spun yarn production device

A production device and technology of color spinning, which is applied in the field of two-color slub color spinning production devices, can solve problems such as dust removal treatment, poor fiber quality, and affecting the dyeing effect of fiber raw materials, so as to improve quality, improve dyeing effect, and improve convenience. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

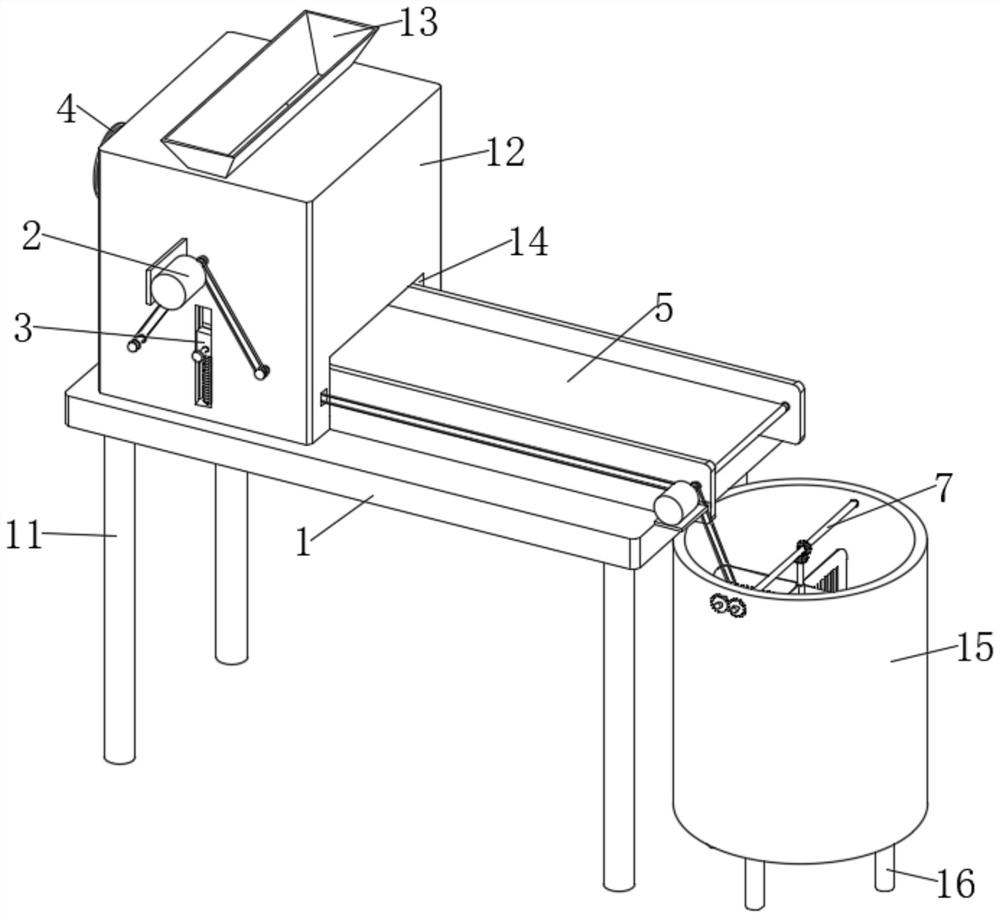

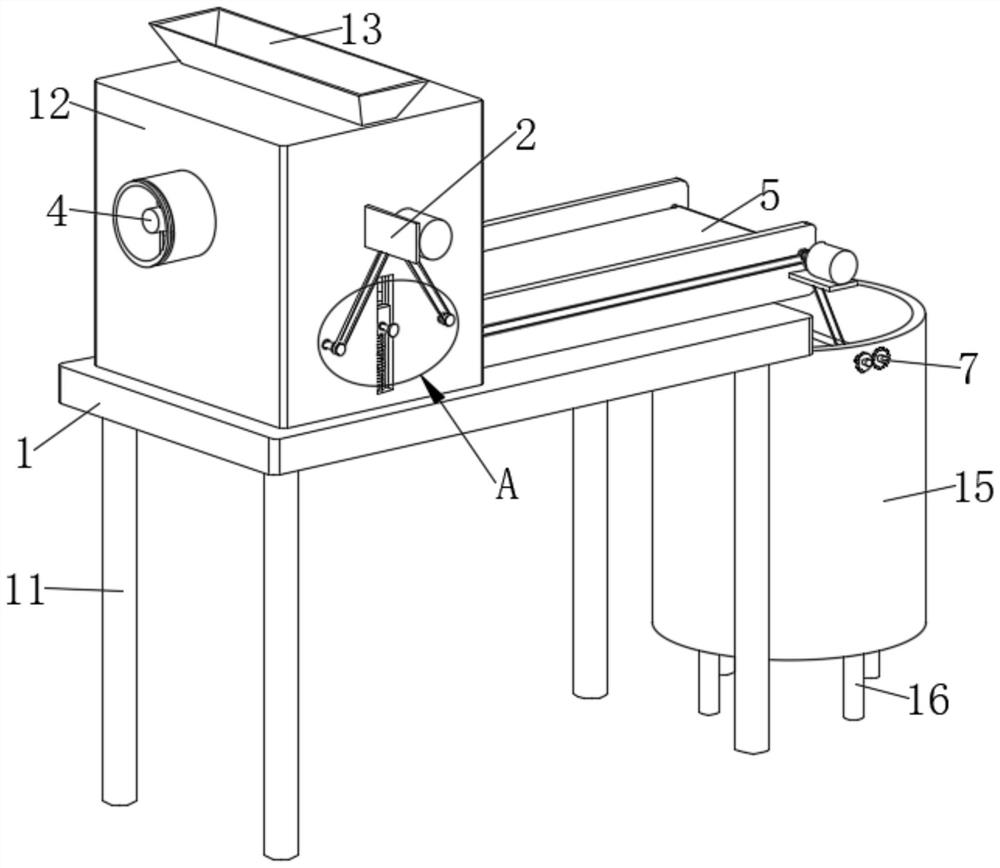

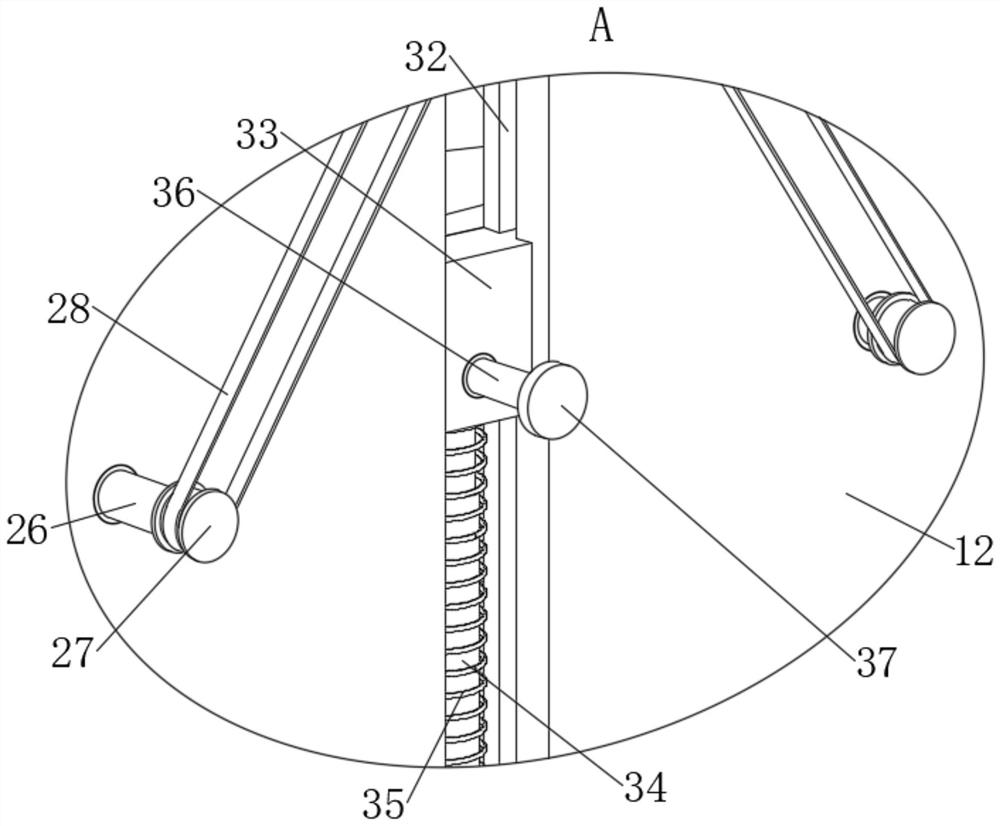

[0035] Example: such as Figure 1-12As shown, the present invention provides a kind of two-color slub color spinning production device, comprises workbench 1 and dyeing bucket 15, and the upper surface of workbench 1 is fixedly installed with dust removal box 12, and one side of dust removal box 12 is provided with discharge Groove 14, the inside of dust removal box 12 is respectively provided with material turning mechanism 2 and material shaking mechanism 3, and material turning mechanism 2 can turn over fiber raw material, and material shaking mechanism 3 can shake fiber raw material, and one side of dust removal box 12 is provided with dust removal mechanism 4 , the dust removal mechanism 4 can remove the cilia in the fiber raw material, and the side of the workbench 1 near the dust removal box 12 is provided with a material delivery mechanism 5, and the material delivery mechanism 5 can transport the fiber material after the dust removal, and the fiber material after the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com