Polyurethane waterproof material production process

A polyurethane waterproofing and production process technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of low yield, problems, poor performance of final products, etc., to achieve accurate measurement control, reasonable storage, and high quality of finished products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

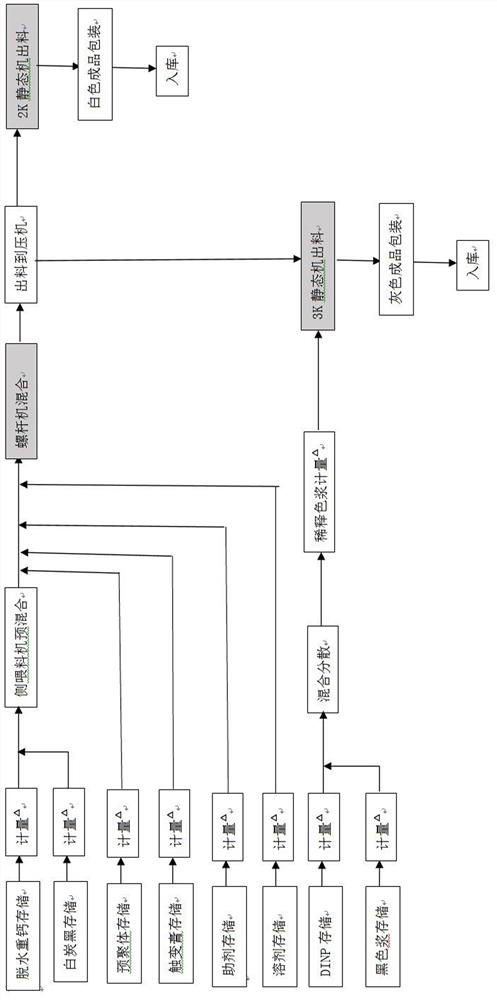

[0038] Such as figure 1 Shown: a polyurethane waterproof material production process, including the following steps:

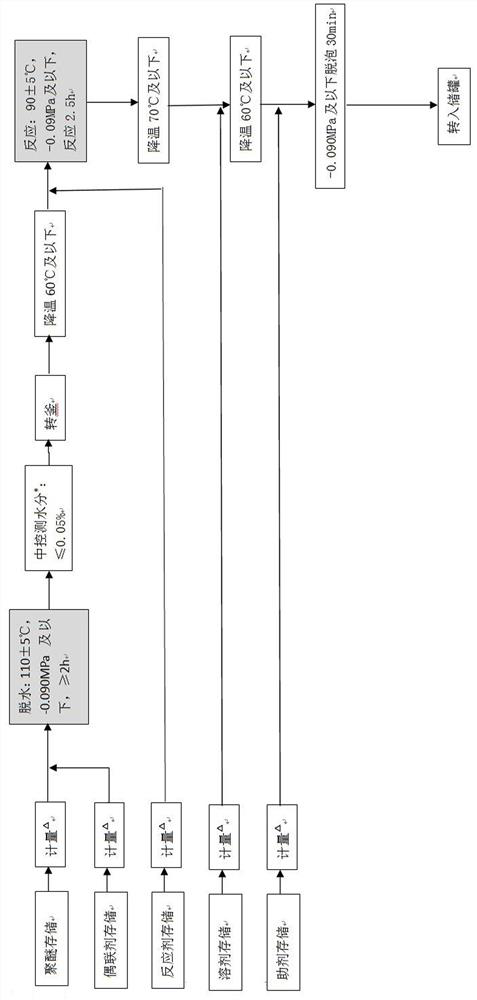

[0039] S1. Production and storage of prepolymer, production and storage of thixotropic paste, dehydration and storage of heavy calcium, production and storage of color paste;

[0040] S2, put white carbon black, auxiliary agent, solvent into tank and store for later use;

[0041] S3. Pre-mix the dehydrated heavy calcium and white carbon black through the side feeder, then add the prepolymer, thixotropic paste, additives and solvents, mix through the screw machine and discharge to the press;

[0042] S4. The final product is divided into white finished product and gray finished product. The white finished product is discharged by a 2K static machine, and the gray finished product is fed into a 3K static machine after the color paste is diluted and mixed with the material before discharging.

[0043] Specifically, during the production process, set the flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com