Electronic metering filling machine

An electronic measurement and filling machine technology, applied in bottle filling, packaging, liquid bottling, etc., can solve the problems of limiting the applicability of filling operations, and achieve the effects of improving production efficiency and accurate measurement control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

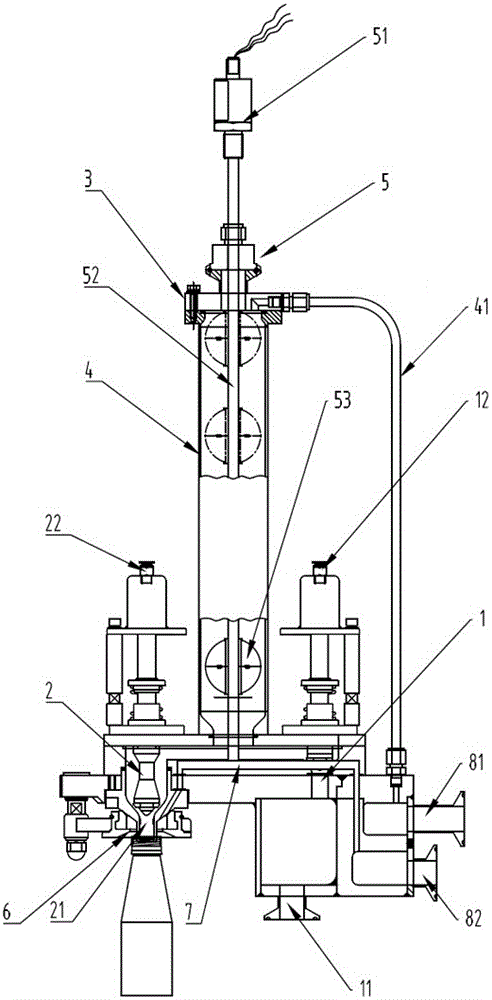

[0015] Specific embodiment one, carry out the filling operation, set the upper and lower limit positions of the floating ball displacement according to the filling volume, set the corresponding threshold value on the electronic controller according to the upper and lower limit positions of the floating ball and the electrical signal of the metering rod, Initially, the filling valve is open and the filling valve is closed. The material is injected through the injection port, the material enters the transition cavity through the injection channel and the material channel, the material supports the floating ball, and as the floating ball rises, the electrical signal of the metering rod increases slowly, and the air in the transition cavity is discharged through the return air pipe , when the electrical signal value reaches the corresponding threshold value of the electronic controller, the electronic controller drives the injection valve to close and the filling valve to open, and...

specific Embodiment 2

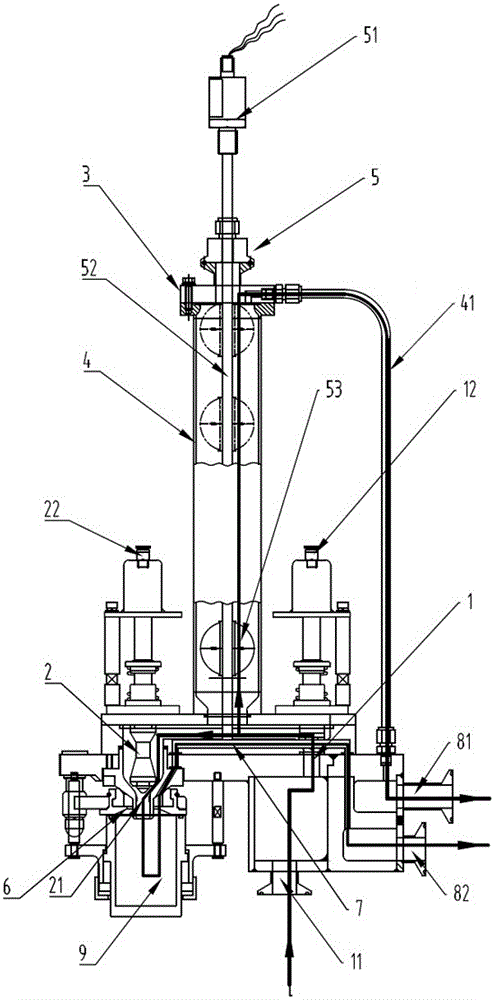

[0017] Specific embodiment two, such as figure 2 As shown, the arrow path is the CIP positioning and cleaning path. To perform the cleaning operation, set the cleaning cup cover on the filling port, turn off the electronic liquid level gauge at the same time, open the filling valve and the filling valve, and then inject the cleaning liquid from the filling port. The cleaning liquid is divided into two ways to clean the filling machine, one of which is along the injection channel and material channel to the transition chamber, then from the transition chamber to the air return pipe, and finally discharged from the return chamber of the air return pipe; the other is along the injection channel and the material After the passage to the filling passage, it is divided into two strands, one enters the cleaning cup to clean the filling port and its periphery, and the other strand is discharged along the return cavity of the positioning and cleaning return passage after being position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com