Cable processing multi-production-line pay-off guide device

A guiding device and production line technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of inconvenient mutual installation and combination, unfavorable device connection and stability, and inability to realize the function of pay-off guiding, etc. It is convenient for processing and production work, and it is beneficial to use and install the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

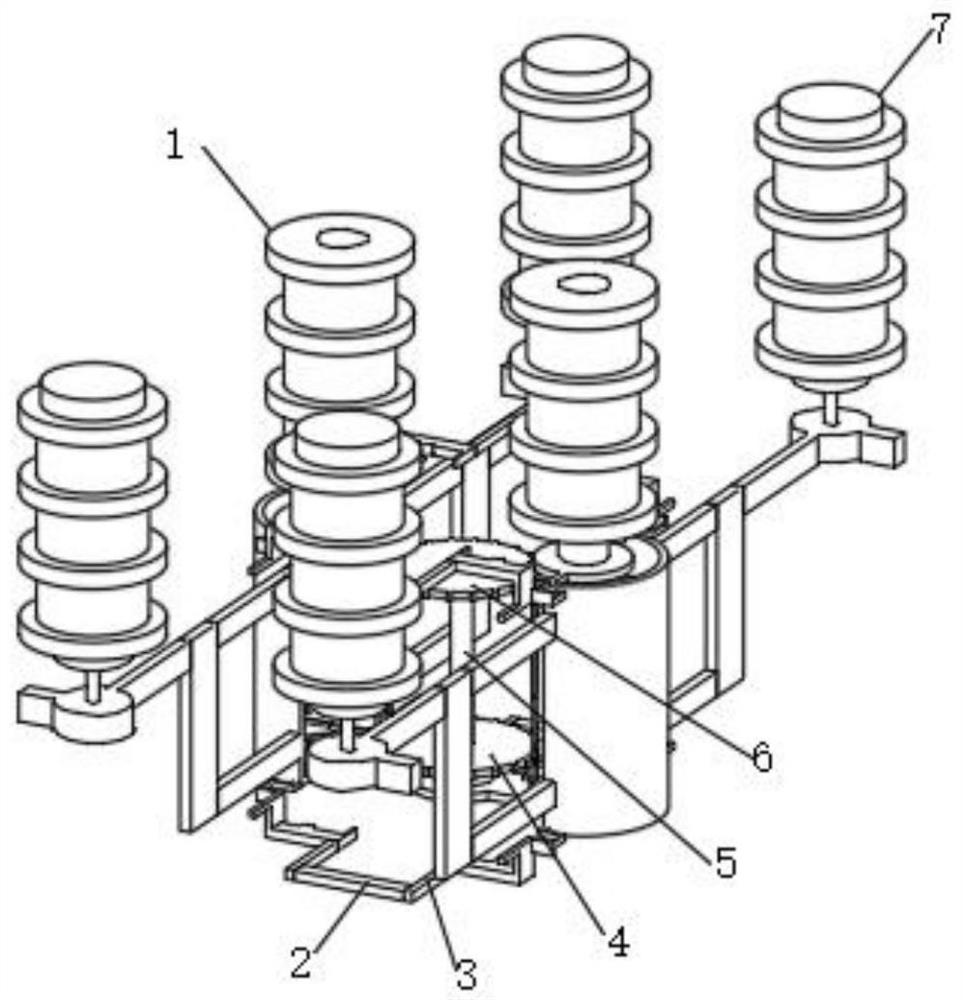

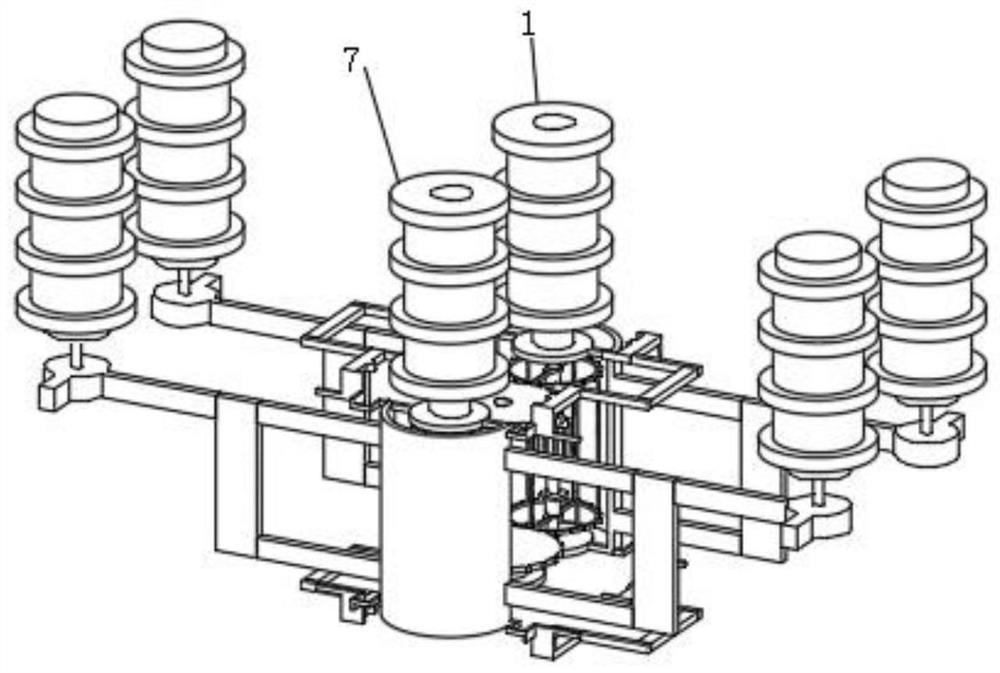

[0041] Such as Figure 1-3 As shown, a cable processing multi-production line pay-off guide device, it includes a first pay-off structure 1 and a second pay-off structure 7, the side end of the first pay-off structure 1 is fixed to the second pay-off structure 7 connection, the first pay-off structure 1 and the second pay-off structure 7 are fixedly connected with a support stabilizer 2, and the side ends of the support stabilizer 2 are fixedly connected with the truss 3, and the first pay-off structure 1 and the center position of the second pay-off structure 7 are meshingly connected with a first driving toothed plate 4 and a second driving toothed plate 6, and a conductive connection is fixedly connected between the first driving toothed plate 4 and the second driving toothed plate 6. pole 5;

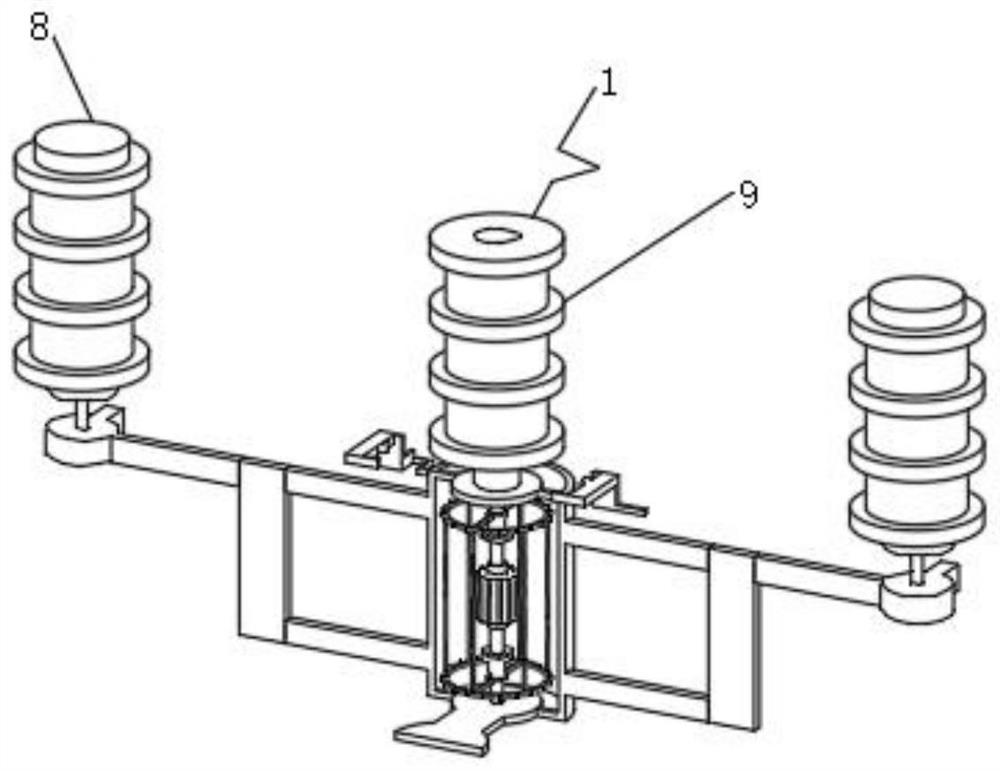

[0042] The first pay-off structure 1 includes a mounting part 8 and an active part 9. The center position of the installation part 8 is nested with the active part 9. Through the fi...

Embodiment 2

[0044] Such as Figure 1-4 As shown, as a further optimization scheme of the above embodiment: a cable processing multi-production line pay-off guide device, which includes a first pay-off structure 1 and a second pay-off structure 7, the side end of the first pay-off structure 1 It is fixedly connected with the second pay-off structure 7, and a supporting and stabilizing frame 2 is fixedly connected between the first paying-off structure 1 and the second paying-off structure 7, and the side ends of the supporting and stabilizing frame 2 are fixed with the truss 3 connection, the first drive toothed plate 4 and the second drive toothed plate 6 are meshed and connected at the center position of the first wire release structure 1 and the second wire release structure 7, and the first drive tooth plate 4 and the second drive tooth plate 4 are connected to each other. A transmission rod 5 is fixedly connected between the toothed discs 6;

[0045] The first pay-off structure 1 inc...

Embodiment 3

[0047] Such as Figure 1-5 As shown, as a further optimization scheme of the above embodiment: a cable processing multi-production line pay-off guide device, which includes a first pay-off structure 1 and a second pay-off structure 7, the side end of the first pay-off structure 1 It is fixedly connected with the second pay-off structure 7, and a supporting and stabilizing frame 2 is fixedly connected between the first paying-off structure 1 and the second paying-off structure 7, and the side ends of the supporting and stabilizing frame 2 are fixed with the truss 3 connection, the first drive toothed plate 4 and the second drive toothed plate 6 are meshed and connected at the center position of the first wire release structure 1 and the second wire release structure 7, and the first drive tooth plate 4 and the second drive tooth plate 4 are connected to each other. A transmission rod 5 is fixedly connected between the toothed discs 6;

[0048] The first pay-off structure 1 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com