Design and machining method of automobile closed section structural member with multiple cavities and variable wall thickness

A technology of closed section and processing method, applied in the direction of structural parts, vehicle parts, motor vehicles, etc., can solve the problems of steel plate springback, bending and wrinkling, and the level of light weight needs to be improved, and achieves the realization of light weight, Solve the effect of bending springback and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0072] The following is an example of the design and processing of battery pack frame parts for automobiles.

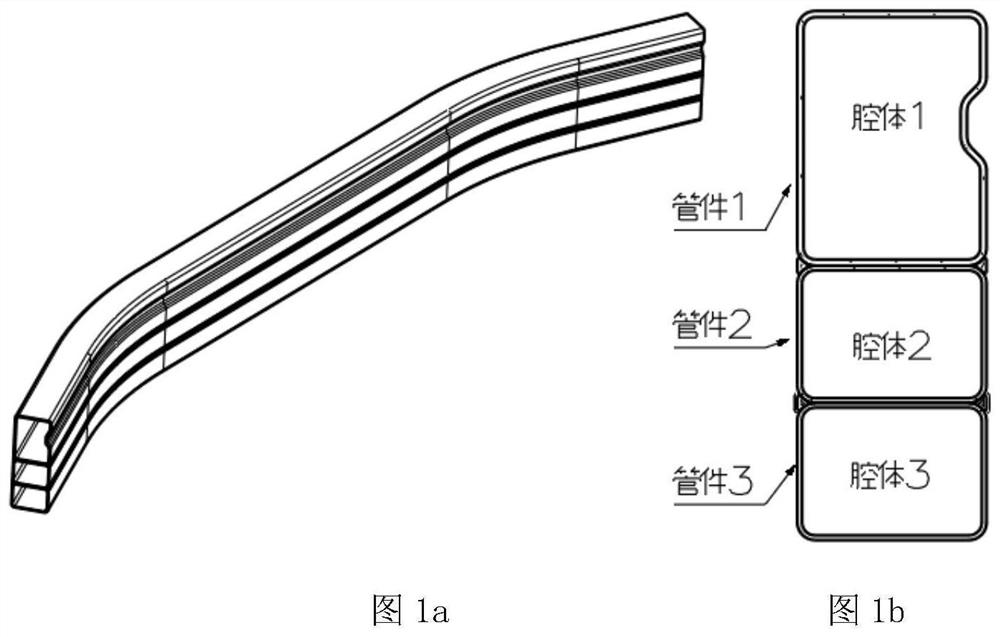

[0073] Schematic diagram of the structure of the battery pack frame Figure 3a As shown, its cross-sectional structure is as Figure 3b shown in .

[0074] The battery pack frame is composed of a first rectangular tube (referred to as rectangular tube 1 or tube 1, the same below) and a second rectangular tube (referred to as rectangular tube 2 or tube 1, the same below), and the first and second rectangular tubes have the same The length and curved features are connected by two laser welds to form a closed section with two cavities.

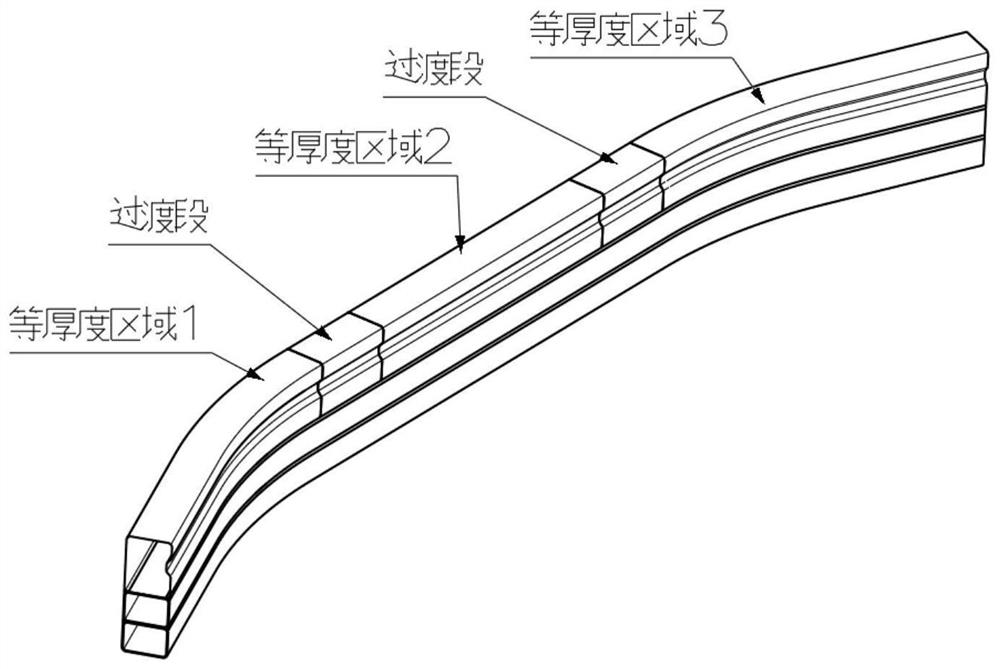

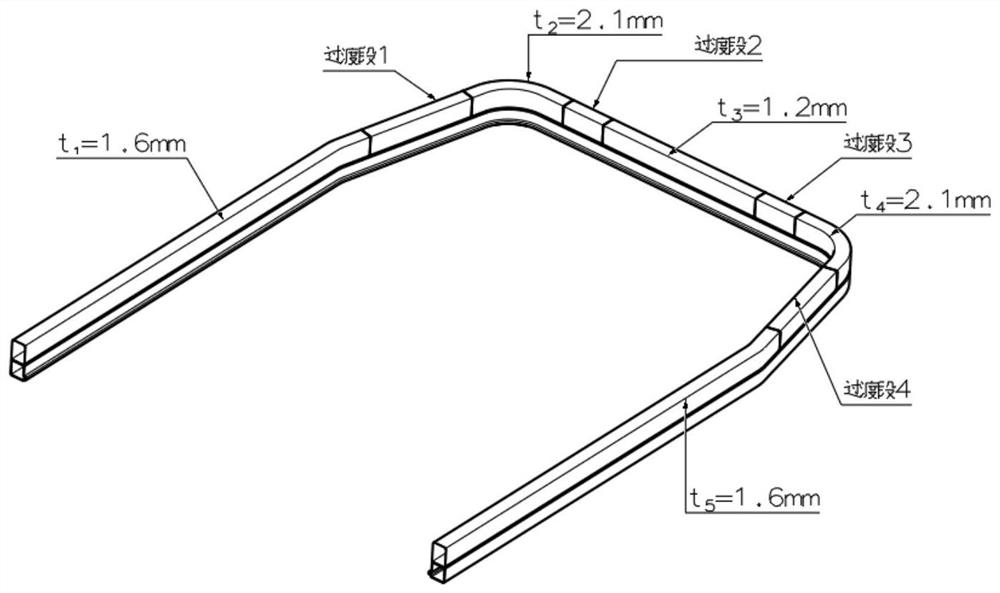

[0075] Pipe fitting 1 is made of B1500HS hot stamping steel material, the wall thickness adopts VRB variable thickness design, and the thickness is designed to be 1.2 / 1.6 / 2.1mm. Figure 4 shown in .

[0076] The length of transition section 1 and transition section 4 is 250mm, and the length of transition section 2 and transition sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com