High-strength anti-collision beam for agricultural machinery

A high-strength, anti-collision beam technology, used in vehicle safety arrangements, bumpers, transportation and packaging, etc., can solve problems such as damage to other people or agricultural machinery, low safety, and no anti-collision beam installed, to improve replacement and maintenance. Efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

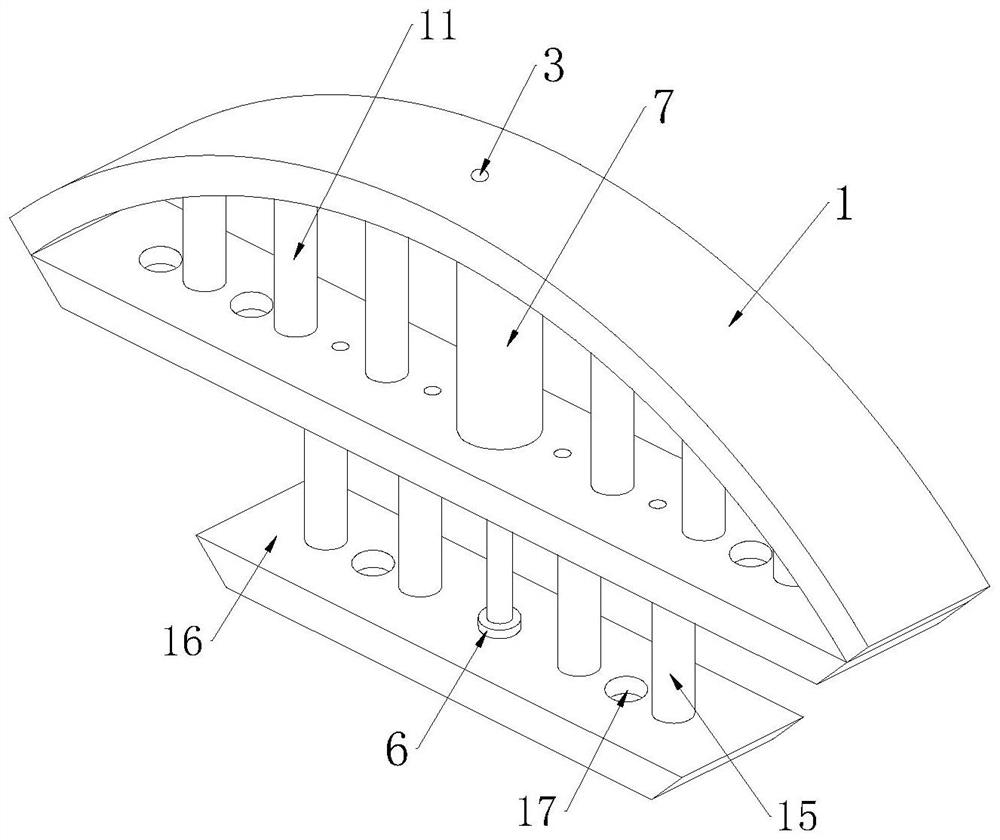

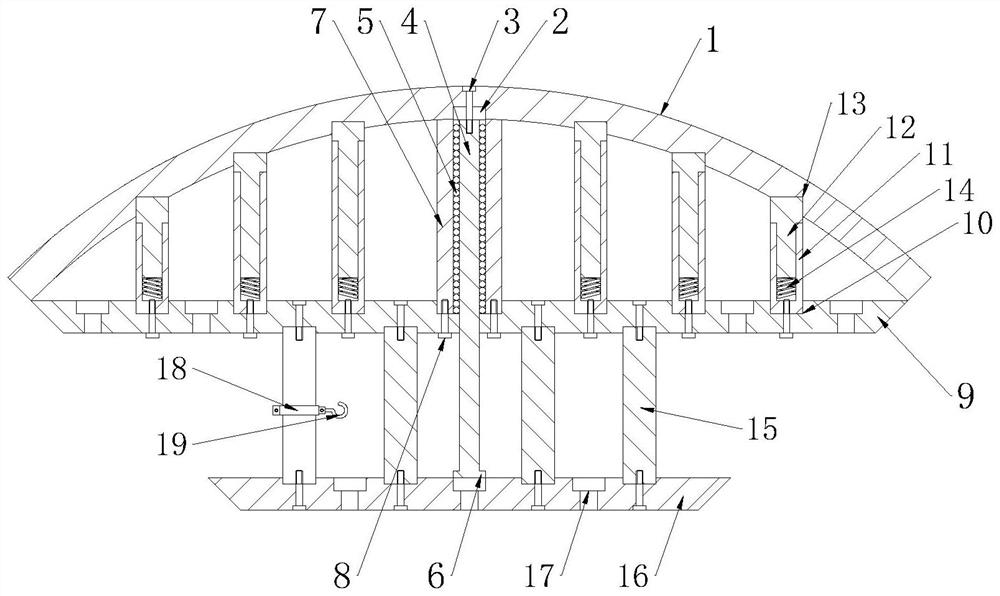

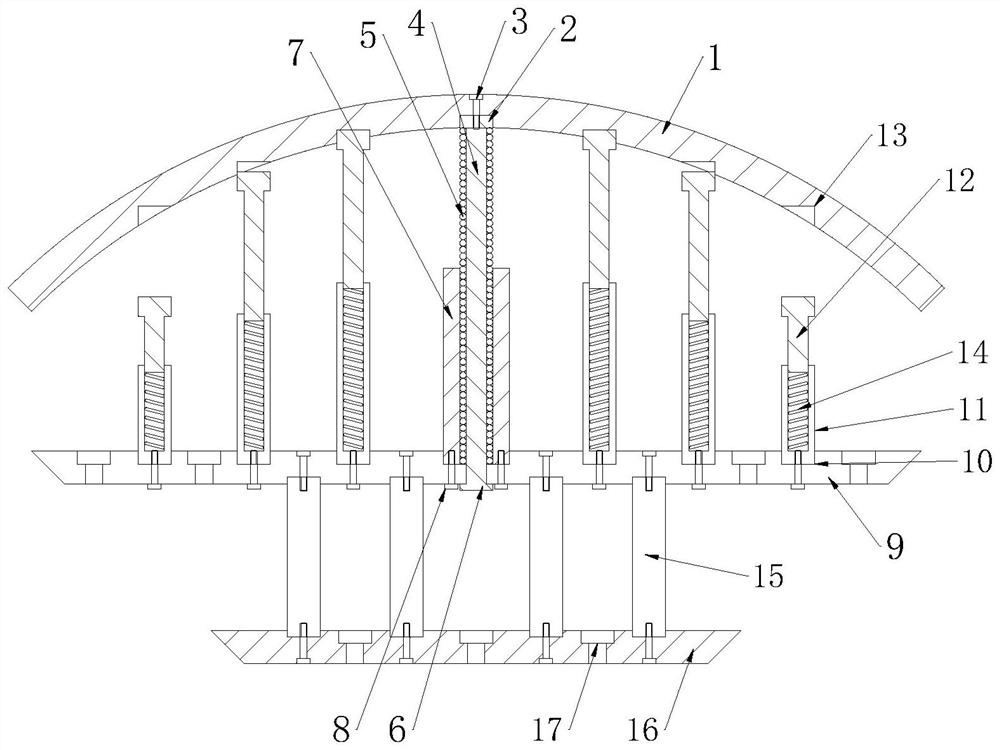

[0023] see Figure 1-4 As shown, a high-strength anti-collision beam used by agricultural machinery includes an arc-shaped anti-collision plate (1), a fastening installation block (2) and an elastic buffer unit; the inner side of the arc-shaped anti-collision plate (1) is opened The holes are buckled and connected with a buckled installation block (2); the buckled installation block (2) is provided with an elastic buffer unit; the elastic buffer unit includes a first fastener (3), a compression guide shaft (4) and the first elastic member (5); the compression guide shaft (4) is threadedly fixed on the fastening installation block (2) through the first fastener (3); the compression guide shaft (4) is sleeved There is a first elastic member (5); the guide tube (7) is slidingly sleeved on the compression guide shaft (4); the guide tube (7) is fixed in the middle of the anti-collision through the second fastener (8) on the plate (9); the lower end of the anti-collision middle pla...

Embodiment 2

[0030] see Figure 5 As shown in Comparative Example 1, as another embodiment of the present invention, the lower end of the anti-collision middle plate (9) is threadedly connected with a threaded column (22); the threaded column (22) is movable sleeved with Movable sleeve (21); the end thread of the threaded column (22) is fixedly connected to the limit ring (20); when working, the movable sleeve (21) is sleeved on the threaded column (22), so that the movable sleeve Pipe (21) can be rotated on threaded post (22), thereby the thing that hangs on movable casing (21) can reduce the frictional force with threaded post (22), prevents from wearing and tearing off.

[0031]The working principle is to push away the compression guide shaft (4) and the guide tube (7) through the first elastic member (5), so that the initial position of the compression guide shaft (4) is that the upper half exceeds the guide tube (7), so that the arc The arc-shaped anti-collision plate (1) moves under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com