Multi-point straight ejection glue feeding mechanism of injection mold

An injection mold, straight top technology, applied in the coating and other directions, can solve the problems of improper welding line position, affecting product strength, unsightly welding line, etc., to achieve the effect of easy control and improved product aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

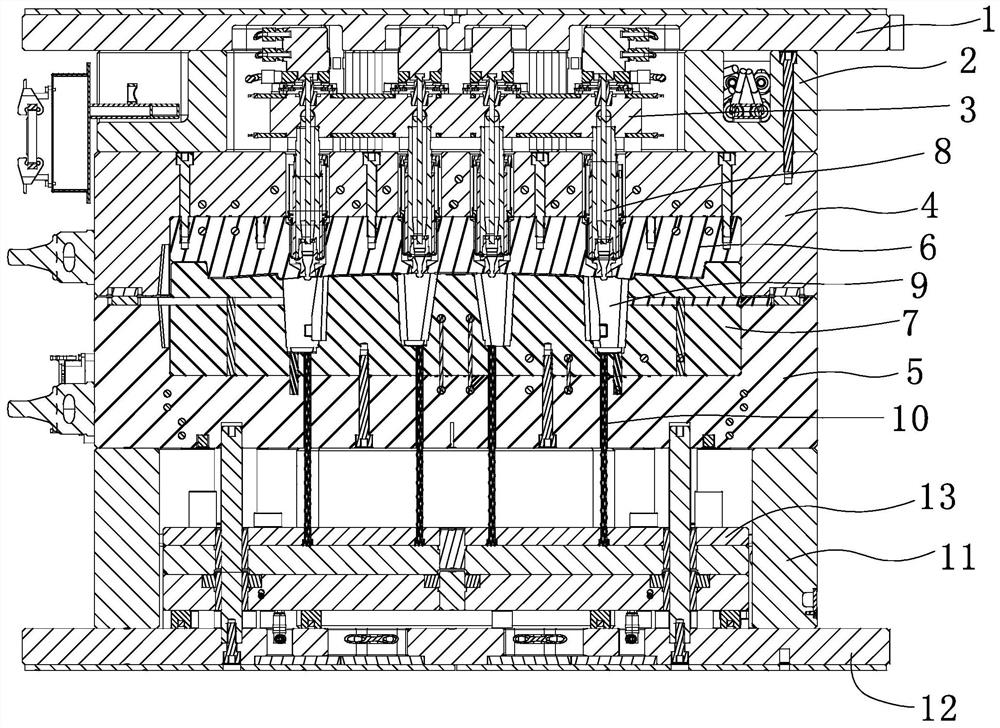

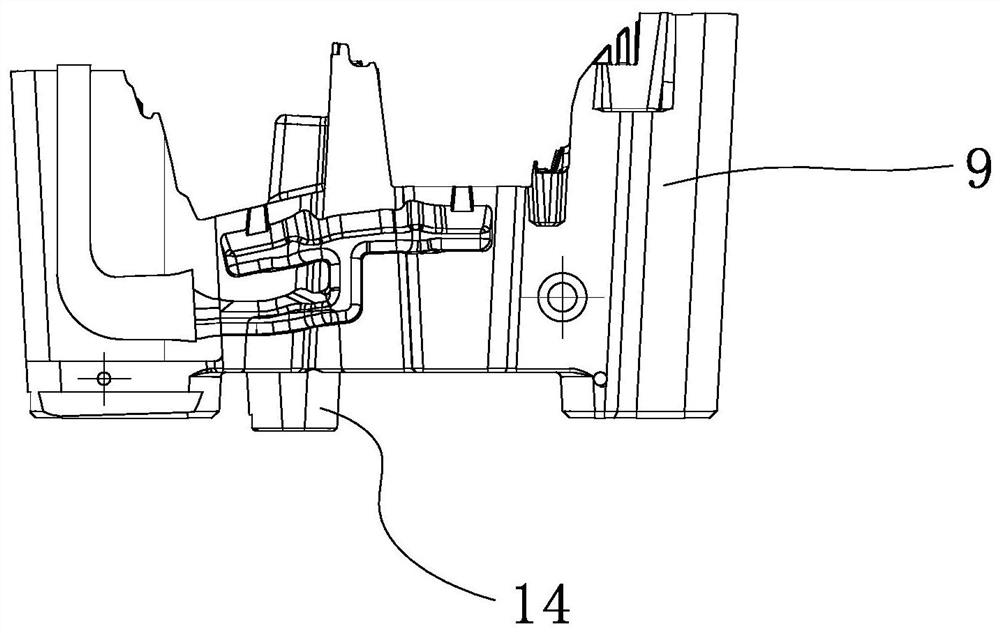

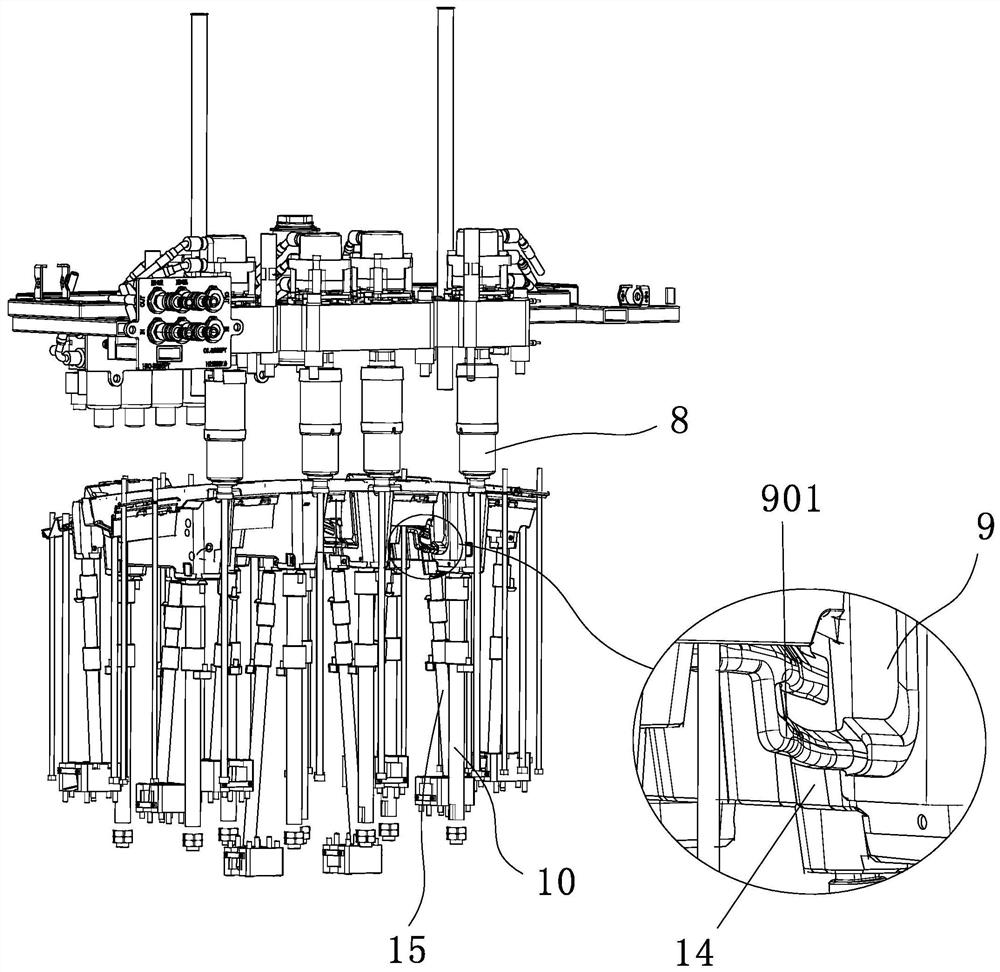

[0031] Such as figure 2 , Figure 4 , Figure 5 In the shown embodiment 1, a multi-point straight jacking glue feeding mechanism for an injection mold includes an upper doubler plate 1, a lower doubler plate 12 and a straight jacking glue feeding assembly, and the straight jacking glue feeding assembly includes a straight jacking block 9 and an inclined The top block 14 is provided with a gate runner 901 for realizing the bottom molding of the product on the straight top block 9. The gate runner 901 includes a runner outlet 902 for product injection, and the runner outlet 902 is opened on the straight top. On the upper end surface of the block 9, the upper end surface of the straight top block 9 is always set close to the ground of the injection molded product 16, and one or several flow channel outlets 902 are set, which are set according to the actual situation of the product. In this application, the flow channel Exit 902 sets one. The straight top block 9 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com