Riveting profiling pier head and mounting method

An installation method and pier head technology, applied in the direction of electrode characteristics, pressure electrodes, etc., can solve the problems of long repair and reconstruction period, achieve the effects of convenient construction, reduce manual operation deviation, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

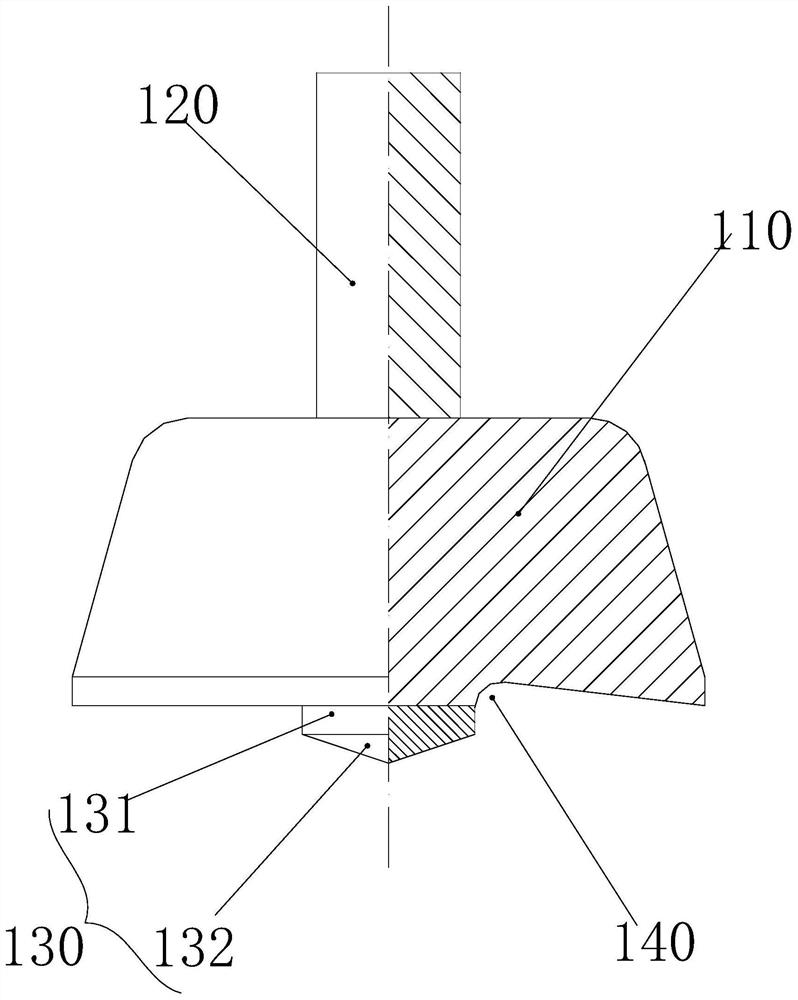

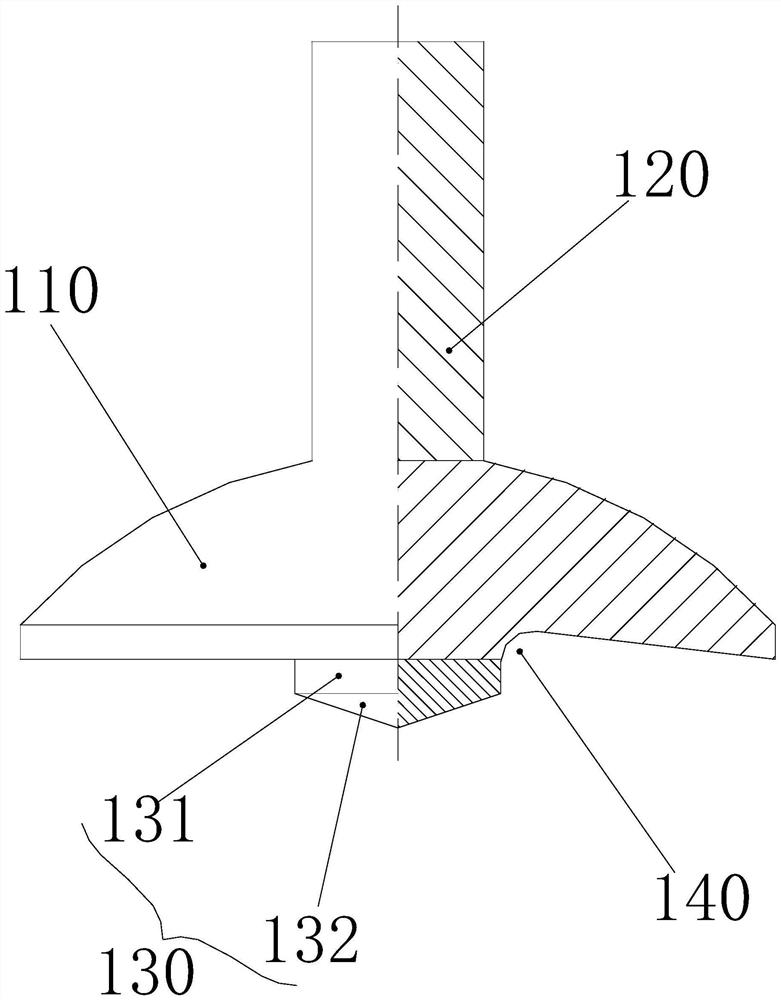

[0070] Embodiment, a kind of installation method of riveted profiling pier head, such as Figure 5-Figure 11 As shown, the method is used to weld the above-mentioned riveted profiling pier head 100 on the surface of the ship's outer plate, and is used to imitate the riveted outer surface of the riveted ship, and the method includes the following steps:

[0071] S10: Obtain the pier head parameters of the profiling area 200, and make an insulating backing plate 300 according to the obtained pier head parameters, and the insulating backing plate 300 is provided with a positioning hole 310 corresponding to the riveting profiling position of the profiling area 200; The distance between the positioning holes 310 on the insulating backing plate 300 is equal to the axis spacing of the piers in the profiling area 200, and the aperture size of the positioning holes 310 on the insulating backing plate 300 is not less than the diameter of the tip of the welding gun, so that the operator c...

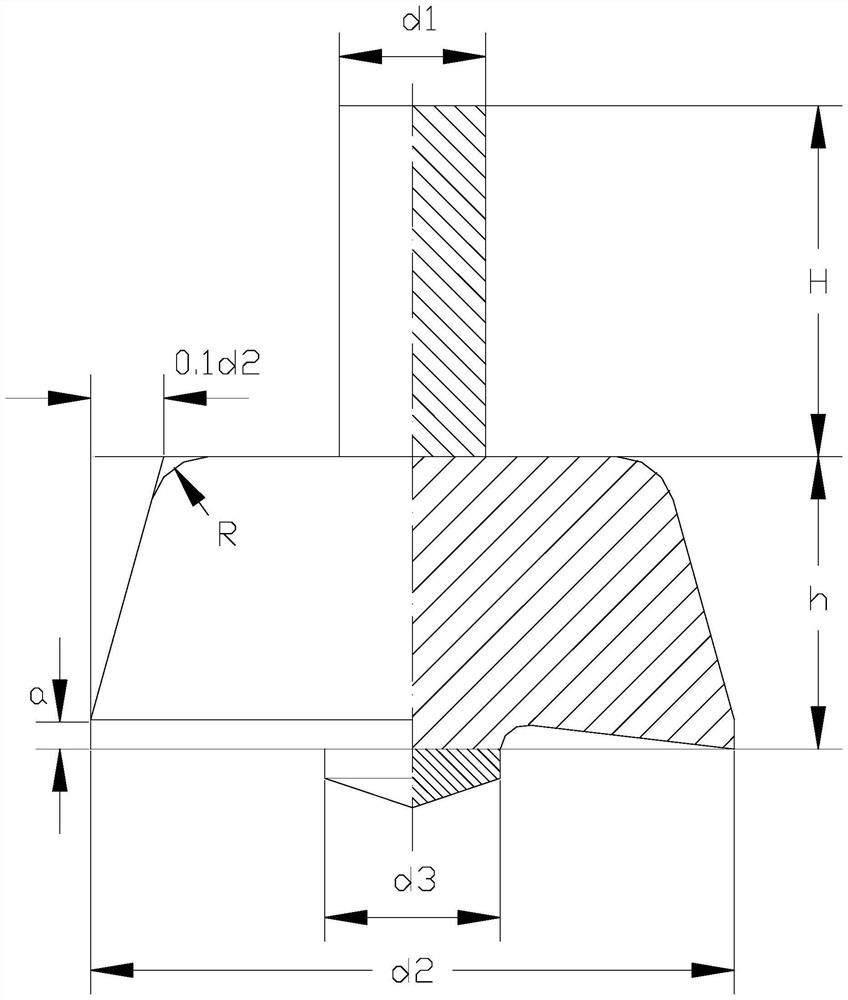

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com