Assembly equipment for processing series capacitor banks

A technology of series capacitors and assembling equipment, which is applied in the direction of packaging capacitor devices, capacitors, and capacitor manufacturing, etc., can solve the problems of expanding the production scale of series capacitor banks, affecting the quality of series capacitor banks, and low assembly efficiency. The efficiency of assembly and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

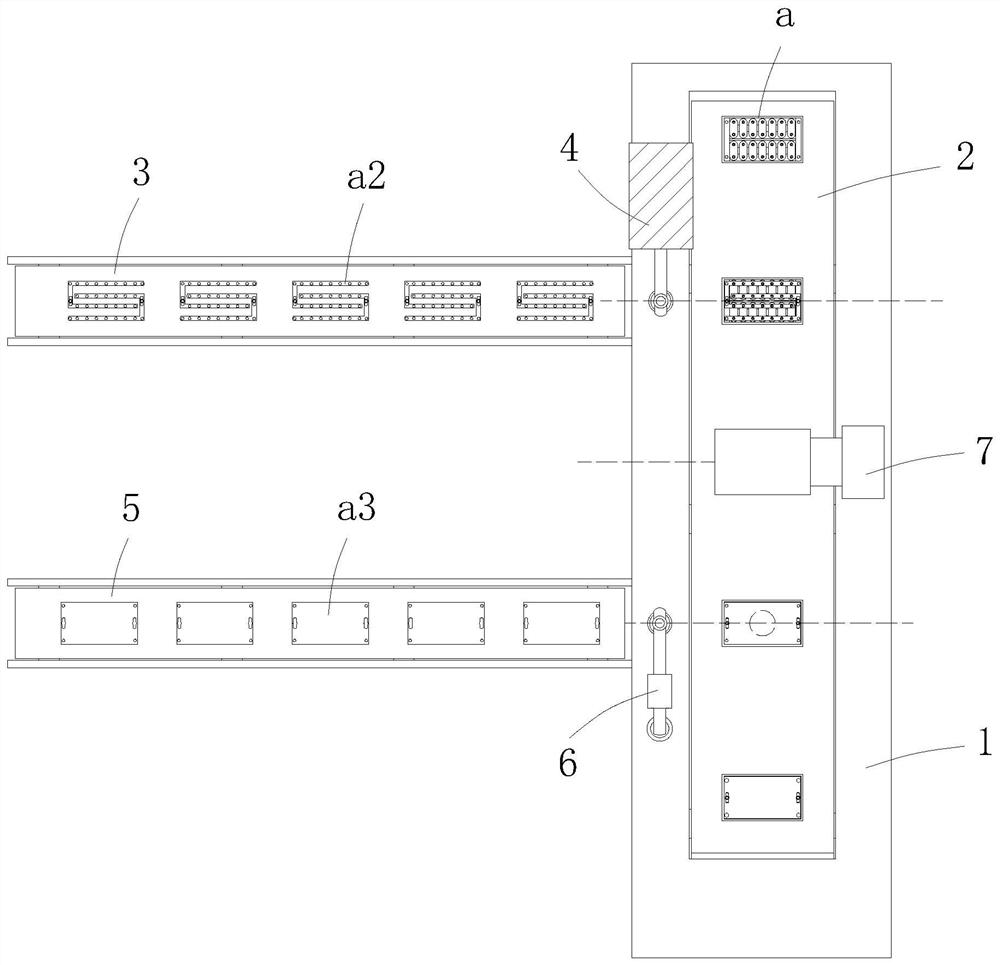

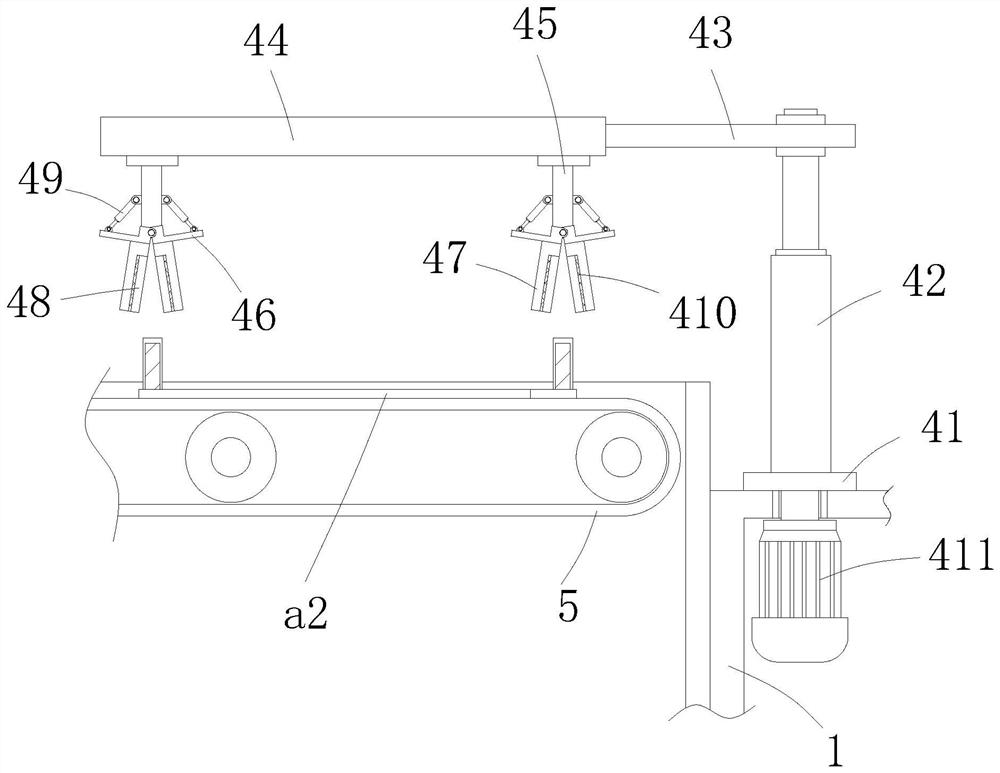

[0038] An assembly equipment for processing capacitor banks in series, comprising an assembly platform 1 and a main belt conveyor 2 installed on the upper end of the assembly platform 1 for transporting the capacitor bank a1, two symmetrically installed on one side of the assembly platform 1 with the main Belt conveyor 2 The parts belt conveyor I3 and parts belt conveyor II5 set vertically to the direction of movement, the parts belt conveyor I3 is used to transmit the series pole piece a2 connected in series to the single capacitor a12 in the capacitor bank a1, the parts The belt conveyor II5 is used to transmit the transmission cover a3 that press-fits and seals the capacitor bank a1;

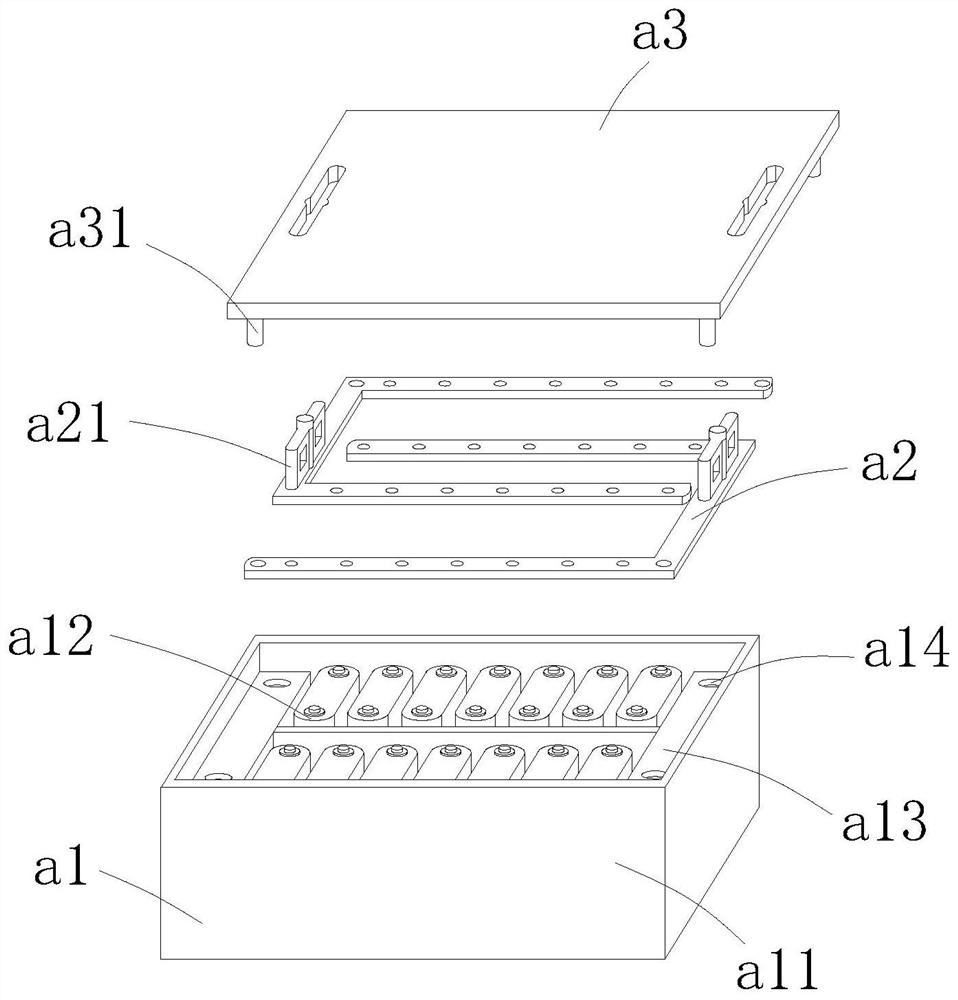

[0039] combined with Figure 6-8 It can be seen that the capacitor group a1 includes the shell a11 and a plurality of single capacitors a12 distributed in a matrix in the shell a11, and the pole piece I and the pole piece II of the single capacitor a12 need to be connected in series through t...

Embodiment 2

[0053] The difference between this embodiment and embodiment 1 is that, as Figure 4 As shown, a pole piece welding mechanism 7 for welding the series pole piece a2 is also provided between the pole piece series mechanism 4 and the cover plate assembly mechanism 6, and the pole piece welding mechanism 7 includes a Inverted L-shaped frame 71 on the wall, two oil cylinders 72 are installed symmetrically on the lower end of the horizontal section of inverted L-shaped frame 71, and the same lifting plate 73 is installed on the telescopic ends of two oil cylinders 72, and lifting plate 73 The lower end of the torch is provided with a welding torch mounting plate 76 in parallel, and a plurality of welding torches 77 inserted and installed from top to bottom are detachably installed on the welding torch mounting plate 76, and the input ends of a plurality of welding torches 77 are connected with the same welding machine 74, and The welding machine 74 is fixedly installed on the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com