Static restraint shoulder drill chuck welding tool and friction static restraint column implanting method

A drill chuck and restraint technology, which is applied in the field of microelectronic packaging, can solve the problems of limited connection strength, flashing reduces the connection area, easy peeling, etc., and achieves the effect of improving the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

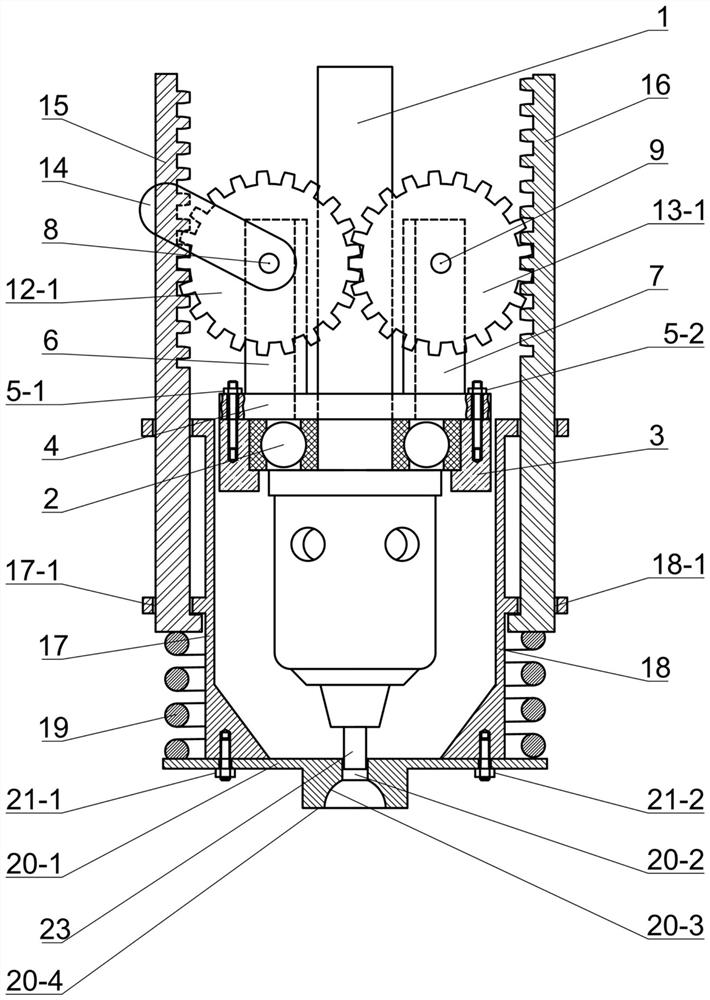

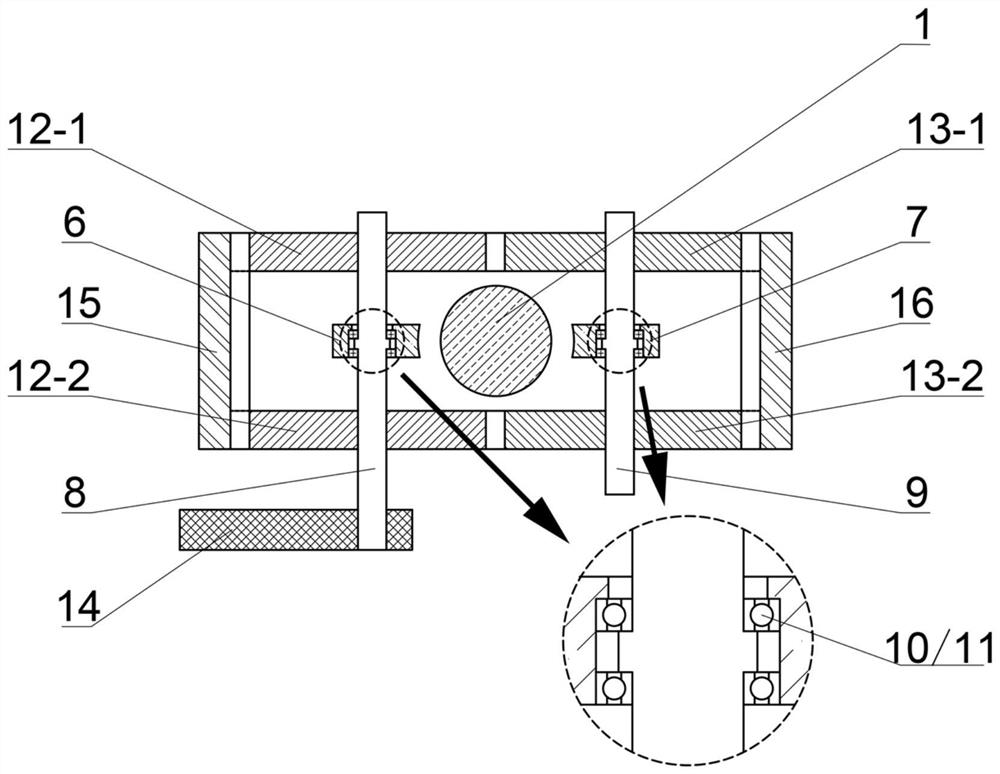

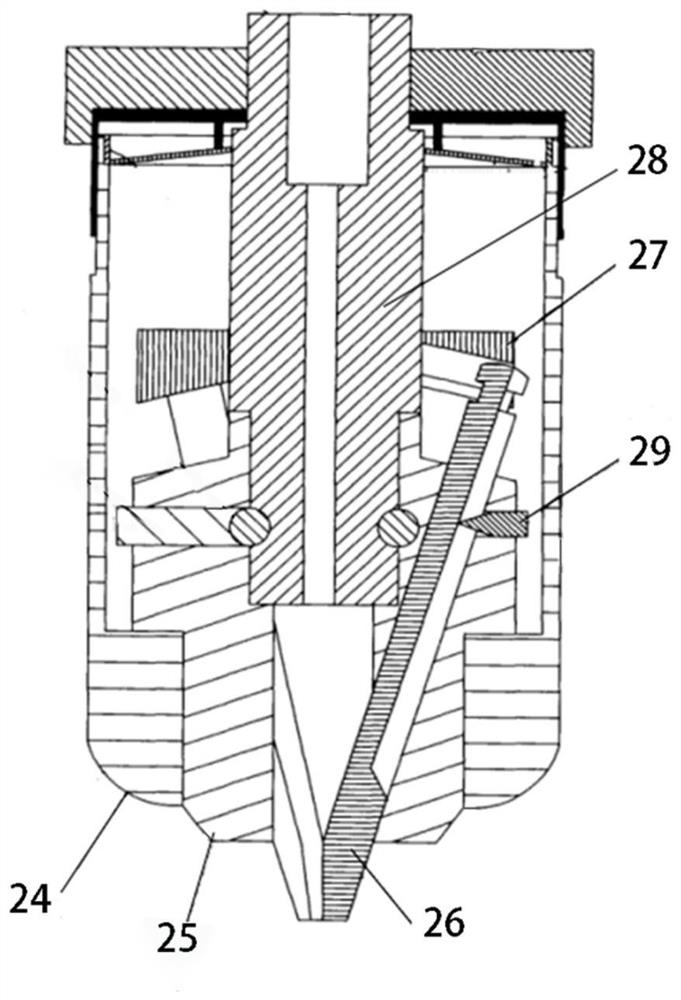

[0037] Specific implementation mode one: combine Figure 1 to Figure 3 This embodiment is described. The static restraint shoulder drill chuck welding tool in this embodiment includes a drill chuck clamping drilling mechanism and a static pressure restraint mechanism. The drill chuck clamping drilling mechanism includes a drill chuck motion transmission mechanism and a drill chuck. Chuck clamping assembly, the drill chuck movement transmission mechanism includes drilling machine spindle 1, spindle bearing 2, spindle sleeve 3, spindle bearing cover 4 and its connecting bolts 5-1, 5-2, the static pressure restraint mechanism Including left fixed plate with holes 6, right fixed plate with holes 7, left gear shaft 8, right gear shaft 9, left gear shaft bearing 10, right gear shaft bearing 11, left gears 12-1 and 12 -2, right gear 13-1 and 13-2, operating handle 14, left drive rack 15, right drive rack 16, left rack guide rail 17, right rack guide rail 18, buffering pressurization ...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 Describe this embodiment, the diameter of the welding post receiving through hole 20-2 of the static pressure restraining shoulder 20 of this embodiment is (1+μ)r, the depth of the welding post receiving through hole 20-2 of the static pressure restraining shoulder 20 is (1+τ)r, r is the radius of the welding post 23 to be planted, μ is 0.05-0.20, and τ is 0-0.50. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0039] Specific implementation mode three: combination figure 1 To illustrate this embodiment, the radius of the spherical crown-shaped pressurized working surface 20-3 of the static pressure restraint shoulder 20 in this embodiment is R(1+K), and the spherical crown-shaped pressurized working surface 20-3 of the static pressure restraint shoulder 20- The height of 3 is R(1-S), the outer diameter of the horizontal shoulder surface 20-4 of the static pressure constraint shoulder 20 is 3.0R-4.0R, R is the radius of the spherical solder ball 22, and K is 0 ~0.15, S is 0.05~0.30. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com