Coating waste liquid solid-liquid separation device

A technology of solid-liquid separation and waste liquid, applied in the direction of filtration separation, separation method, fixed filter element filter, etc., can solve the problems of increased workload, large power consumption, difficult to handle, etc., to reduce the initial investment cost and save The effect of power energy and convenient centralized processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the examples.

[0030] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

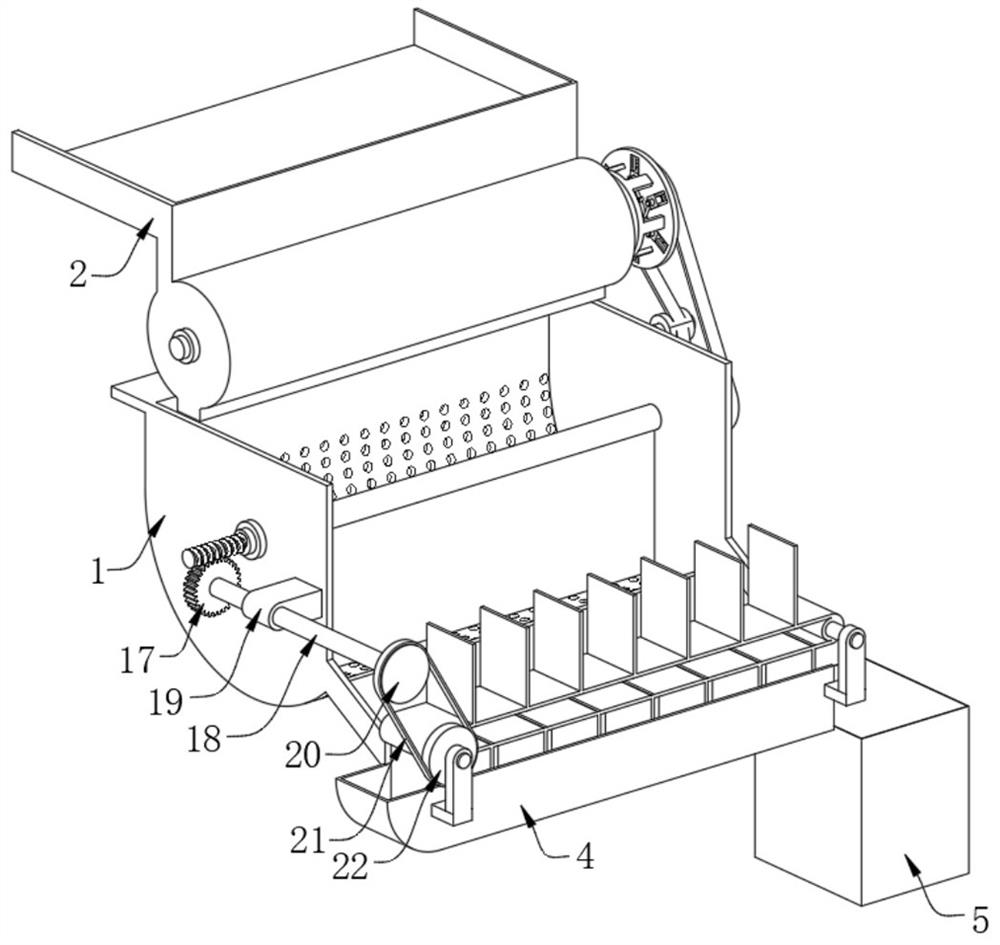

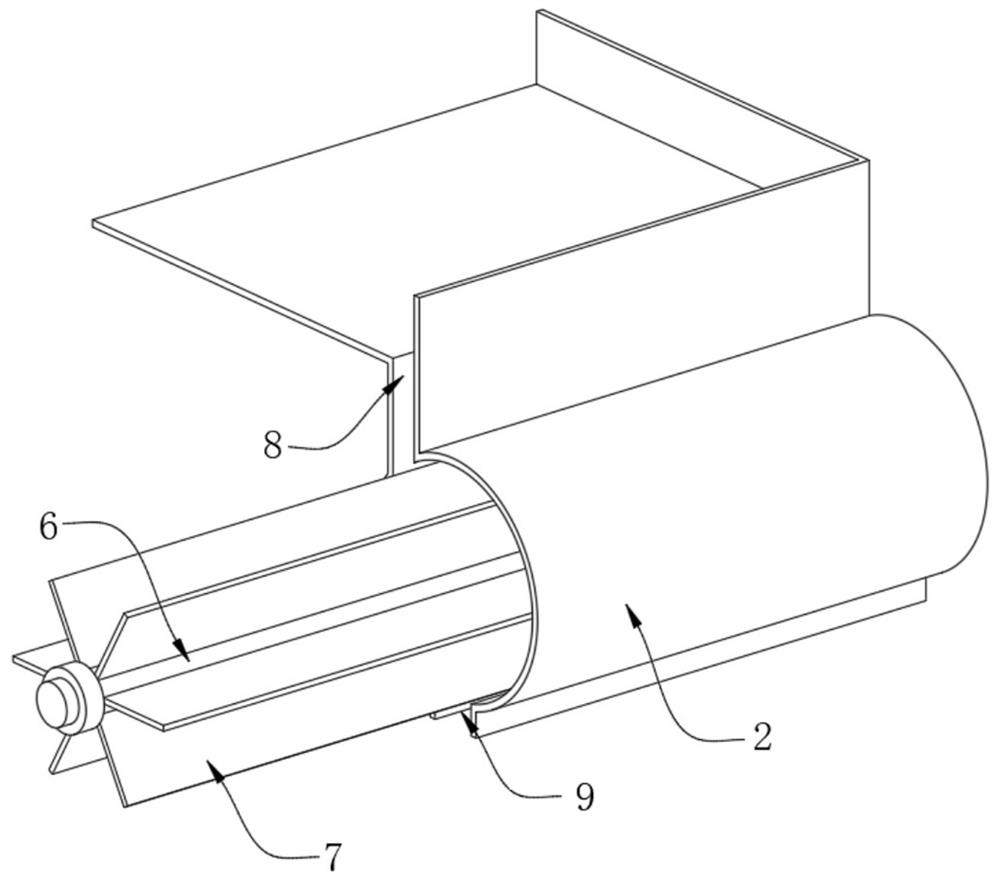

[0031] see Figure 1-8 , the present invention provides a solid-liquid separation device for paint waste liquid, comprising a separation tank 1, the cross section of the separation tank 1 is arc-shaped, and the bottom of the separation tank 1 is provided with mesh holes; the cleaning effect of the cleaning plate 15 can be improved, and the separation is convenient impurities and water.

[0032] The top of the separation tank 1 is fixedly connected with a wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com