Composite stratum recognition system for shield tunneling machine, shield tunneling machine and method

A technology of composite formation and identification system, which is applied in the fields of earthwork drilling, instruments, mining equipment, etc., can solve the problems of insufficiency, narrow operation space of shield machine, and mechanical equipment occupying the main space, etc., and achieves convenient adjustment and high identification accuracy. , easy to optimize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment discloses a complex stratum identification system for a shield machine, including a vibration monitoring device 1, a wireless signal receiving device 2, a brush slip ring and a monitoring terminal.

[0038] The vibration monitoring device is used to be installed on the cutter head of the shield machine to monitor the vibration information of the cutter head in real time.

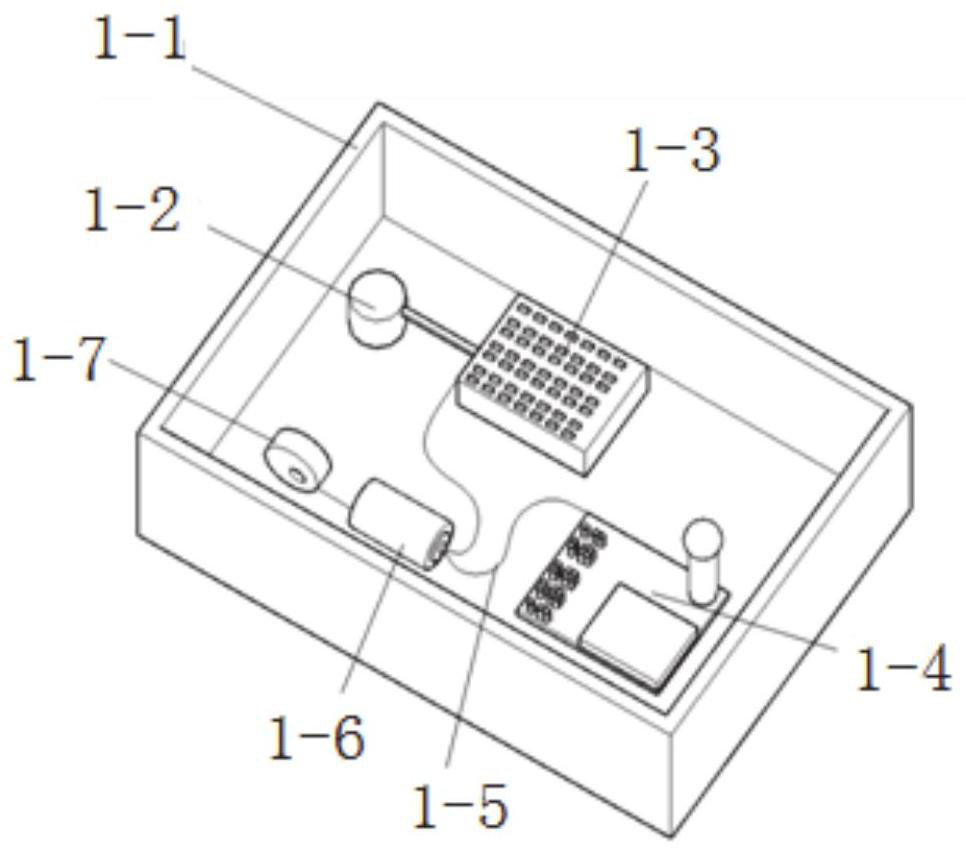

[0039] In this example, if figure 1 As shown, the vibration monitoring device includes a housing 1-1. Preferably, the housing is made of high-strength non-metallic materials, and a signal acquisition system is sealed and installed inside the housing.

[0040] The signal acquisition system includes a vibration sensor 1-2, the vibration sensor can collect the vibration information of the cutter head, and realizes the monitoring of the cutter head vibration information in the shield construction process, and the vibration sensor is connected with the controller 1-3, which can The collect...

Embodiment 2

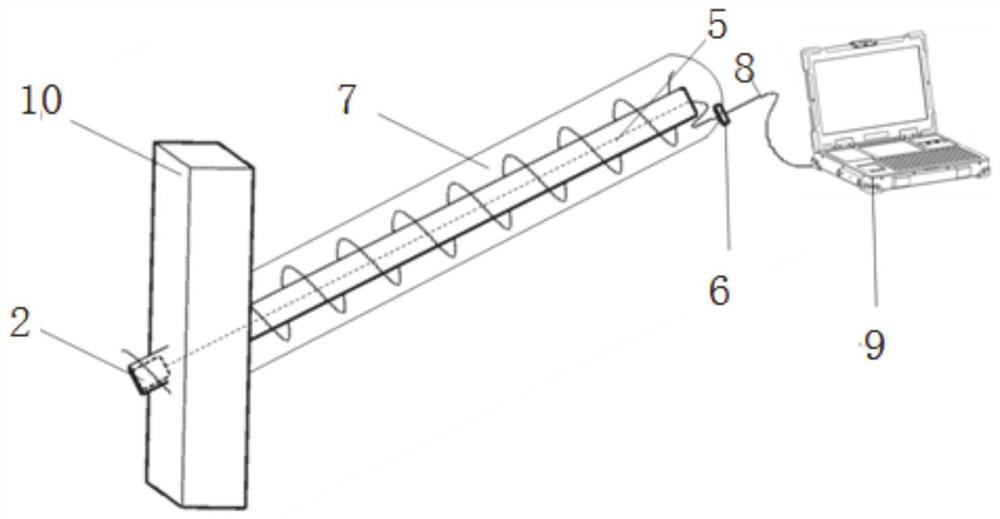

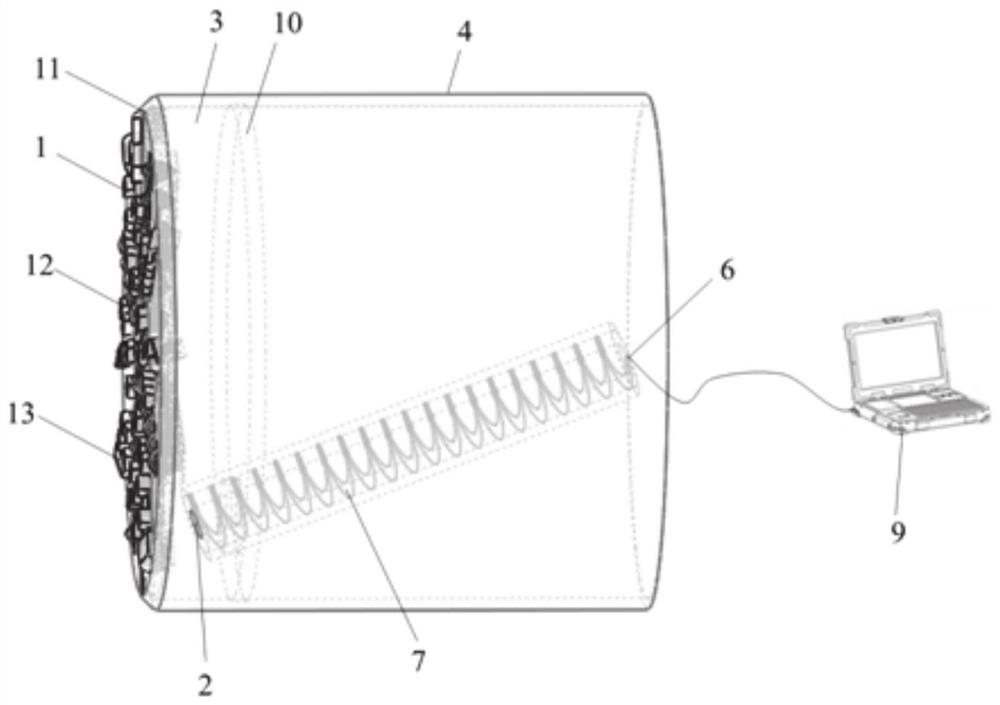

[0051] This embodiment discloses a shield machine, such as Figure 3-Figure 4 As shown, there are parts such as a cutter head 11, a hob 12, a scraper 13, a soil bin 3, a soil bin partition 10, a shield shell 4, and a screw excavator. The above-mentioned parts can be used in the prior art, and will not be described in detail here. , the shield machine complex stratum identification system described in Embodiment 1 is installed on the shield machine, specifically, the vibration monitoring device has a plurality of vibration monitoring devices installed near the cutter head hob or scraper of the shield machine On the web, multiple vibration monitoring devices have different distances from the center of the cutter head.

[0052] The arrangement form of the vibration monitoring device is determined according to the diameter and type of the cutterhead, and 3-6 circles are determined on the cutterhead as the position for arranging the vibration monitoring device. According to the ope...

Embodiment 3

[0059] This embodiment discloses a method for a shield machine to identify composite formations, such as Figure 5 shown, including the following steps:

[0060] Step 1: Process the steady vibration signal of the cutter head when the shield machine is idling and the non-stationary vibration signal of the cutter head generated during the cutting of soil and rock by the shield machine, including digital filter processing and signal waveform spectrum analysis. Through time-domain filtering and frequency-domain filtering processing, the effective wave extraction of shield cutter head vibration signal, the screening of interference wave and the acquisition of frequency characteristic distribution of vibration signal waveform are realized, and the time history of vibration frequency, vibration acceleration and vibration velocity is constructed. curve.

[0061] The vibration sensor obtains the time-history curve of vibration frequency, vibration acceleration and vibration speed, tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com