Multi-stage telescopic operation method for monitoring hole sealing quality of exploration hole in mudstone stratum

An operation method and telescopic technology, applied in underground chambers, earth-moving drilling, wellbore lining, etc., can solve the problem of long-term monitoring of the sealing quality of exploration holes in mudstone formations, inability to fully understand the conditions in the holes, and inability to change the humidity in the holes. Monitoring and other issues to achieve the effect of reasonable and effective monitoring work, improving availability and reliability, and contributing to safety and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

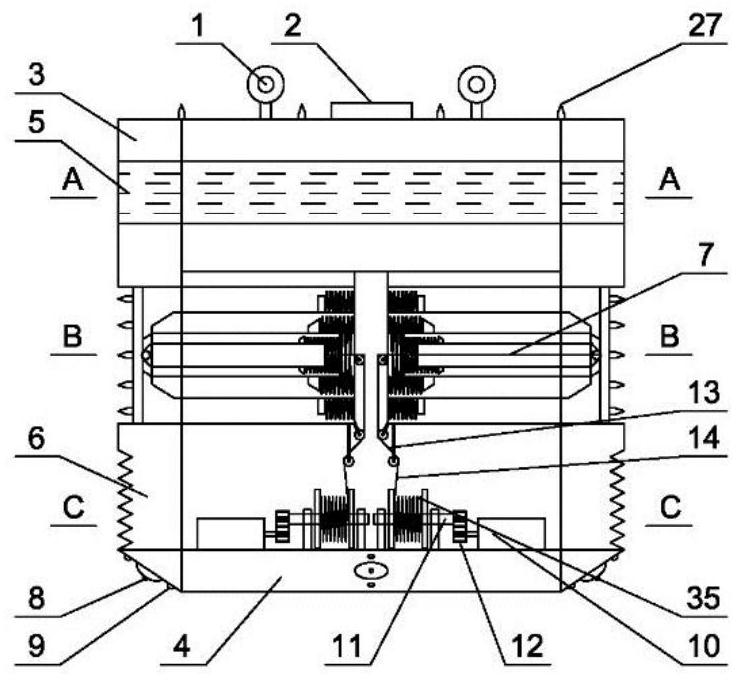

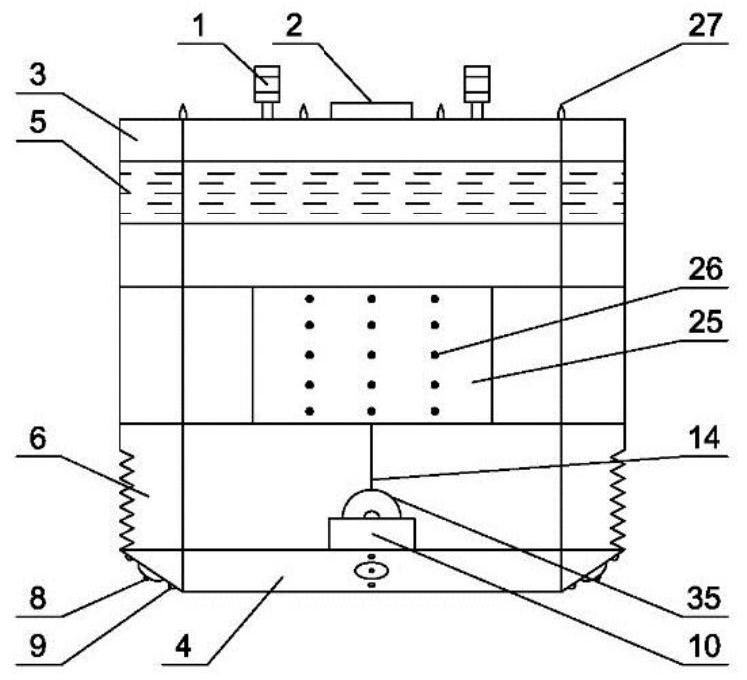

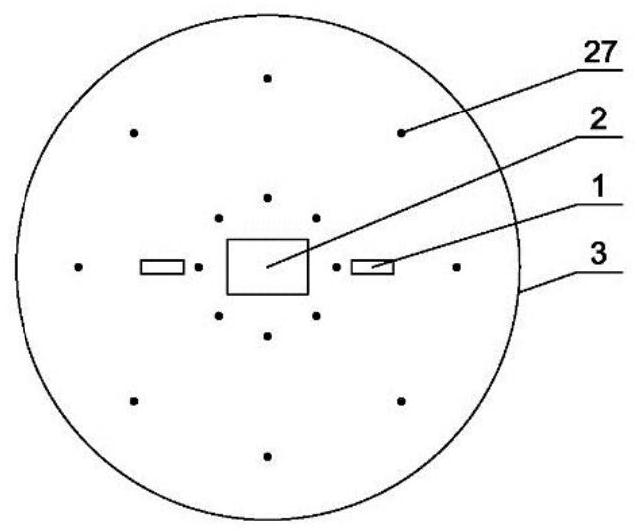

[0050] The present invention will be further described below with reference to the accompanying drawings.

[0051] Refer Figure 1 ~ 22 , Multi-stage method of operating a retractable sealing exploration hole for quality monitoring shale formation, comprising the steps of:

[0052] (1) the deployment apparatus, as follows:

[0053] 1.1 excavation hole exploration, according to the needs and design exploration, determination exploration hole 28 is 31 m depth using XY-100 drill rig excavation exploration holes 28, 28 exploration hole diameter 100mm.

[0054] 1.2 determination of lowering depth. The core samples obtained after 28 exploration excavation hole depth determining apparatus 22 is substantially decentralized to 23 meters, it is located 36 weathered shale calcareous soil.

[0055] 1.3 determine the key parameters of the device. The diameter of the exploration hole 28, 29 is determined decentralized multiplex grouting pipe length 32m, multiplexed with 800mm diameter tube wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com