Three-dimensional seismic advanced detection device and method for rock-breaking seismic source of tunnel boring machine

A technology of tunnel boring machine and three-dimensional seismic, which is applied in measuring devices, seismology, geophysical measurement, etc. It can solve the problems of low signal and noise in seismic records, long detection distance, lack of fast installation devices and methods for geophones, etc., and achieve detection The effect of short time and quick arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

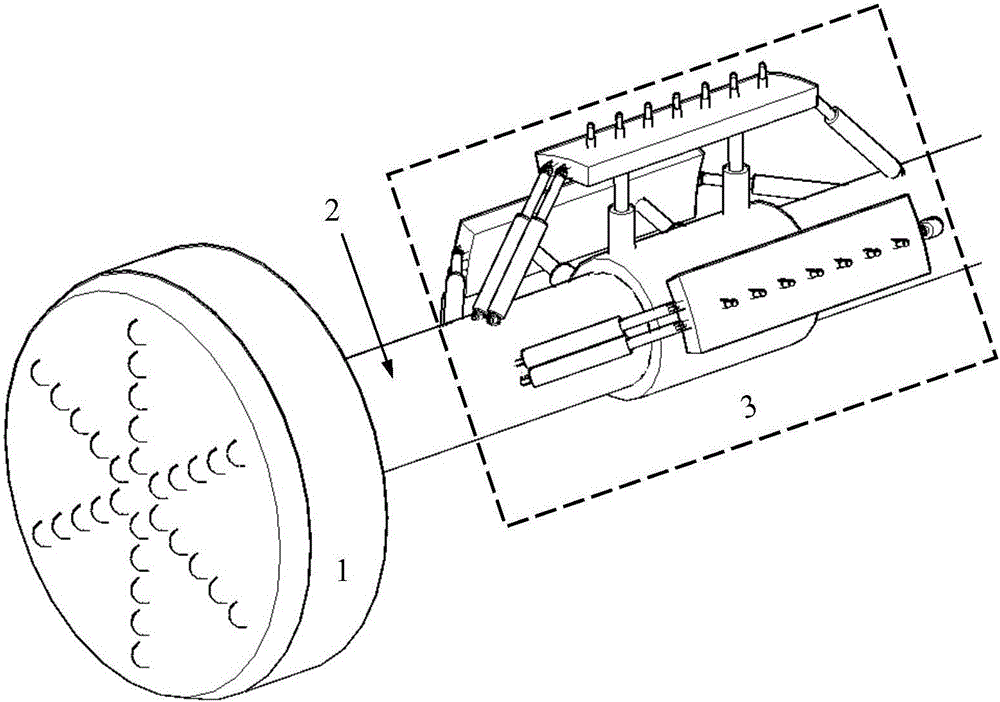

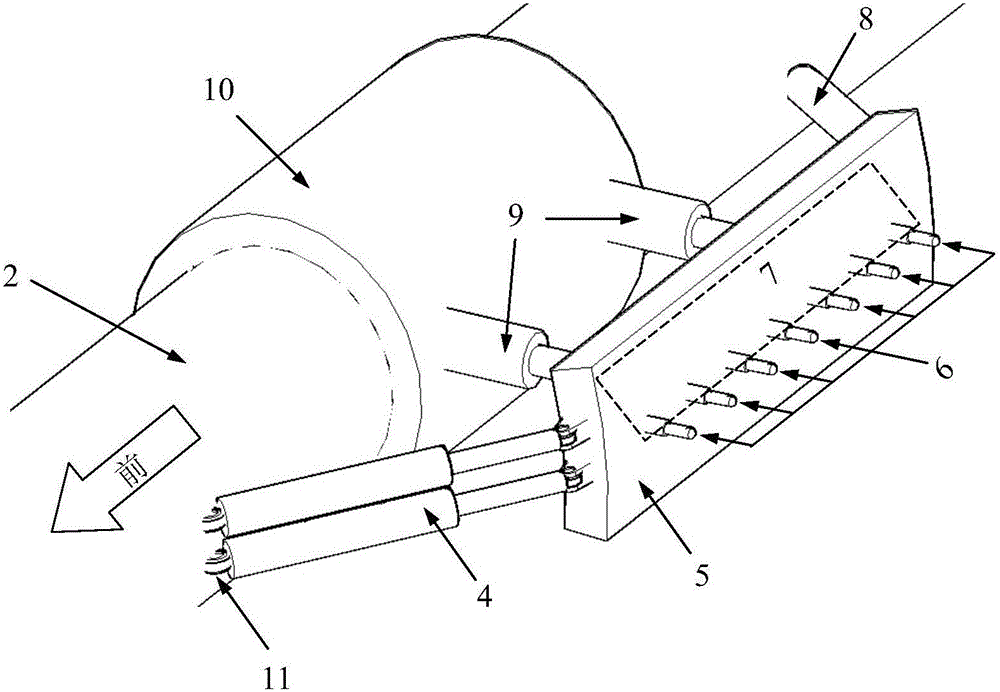

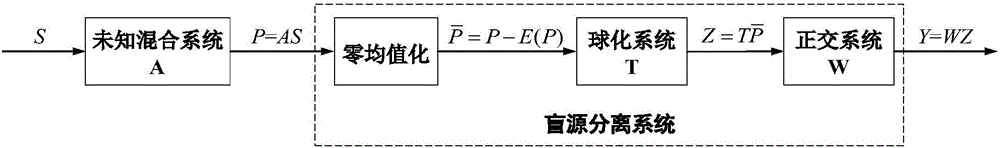

[0054] like Figure 1-Figure 2 , Image 6 As shown, a three-dimensional observation advanced detection device for rock-breaking vibration of a roadheader mainly includes a source sensor array, a receiving sensor and its support device 3, a noise sensor, and a multi-channel seismic wave data acquisition instrument.

[0055] The seismic source sensor array is installed behind the cutter head 1 of the roadheader, and the hobs are grouped according to the specific distribution of the hobs on the cutter head, namely hob group 12-1, hob group 12-2, hob group 12-3, Hob group 12-4, hob group 12-5, hob group 12-6, install vibration source sensors at appropriate positions behind each hob group, respectively vibration source sensor 13-1, vibration source sensor 13-2, vibration source Sensor 13-3, seismic source sensor 13-4, seismic source sensor 13-5, seismic so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com