Method and system for removing oligomer pollution

An oligomer and filter material technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of increased labor intensity, high operating costs, inconvenient operation, etc., to reduce labor intensity, system Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

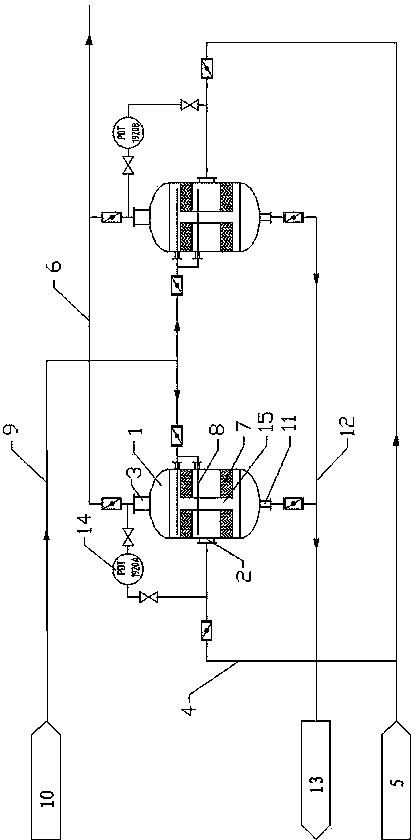

[0019] The invention provides a method for removing oligomer pollution. Inert alumina ceramic balls are used as oligomer filter materials, which have adsorption capacity for oligomers. The oligomers in the filter are deposited on the filter material, and the oligomers deposited on the filter material are cleaned by high-temperature steam purging. After cleaning, the filter material is not clogged and can be reused. The inert alumina ceramic ball is a regular sphere with a diameter of 8mm, containing 45-70% of Al2O3, such as 45%, 50%, 60% or 70% of Al2O3; its water absorption is less than 5%, such as Water absorption rate is 4%, 3% or 2%; acid resistance is greater than 98%, such as acid resistance is 98.5%, 99% or 99.5%; alkali resistance is greater than 85%, such as alkali resistance is 90%, 95% or 98 %; Mohs hardness is greater than 7; the temperature resistance to sudden temperature changes is 500°C; the bulk specific gravity is 1500-1600kg / m 3 , such as the specific gravi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com