Acidification oil-water purification energy-saving device

An energy-saving device and oil-water technology, which is applied in fatty acid production, fatty acid preparation/refining, etc., can solve the problems of large power consumption, large water consumption, and ineffective effects, so as to save power output, work safety, and improve manual operation safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

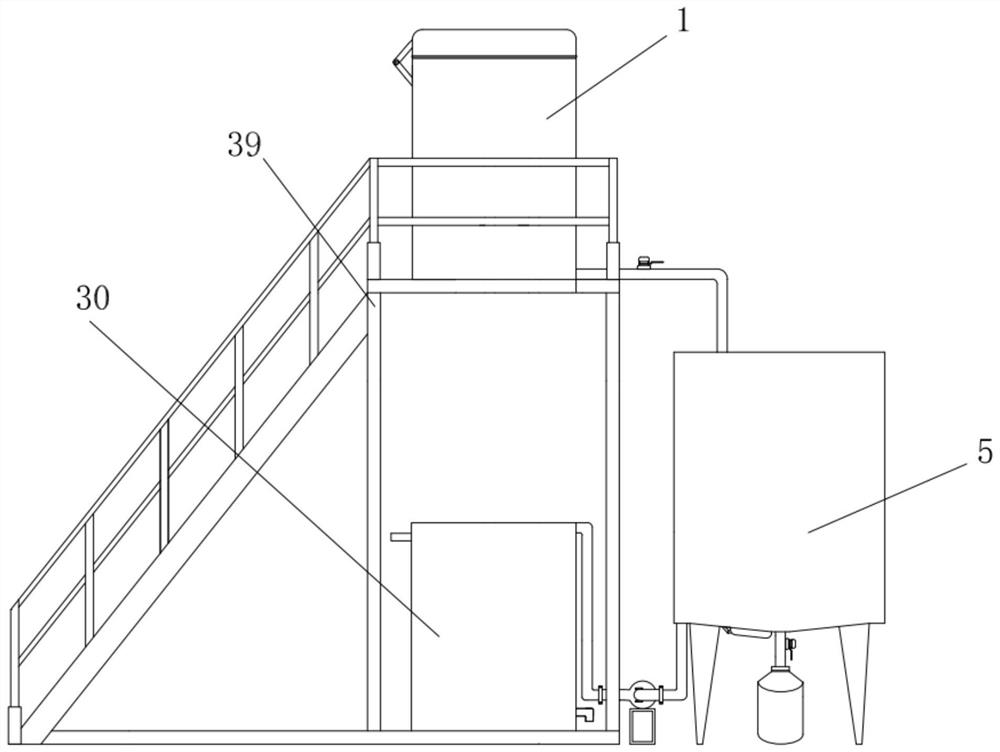

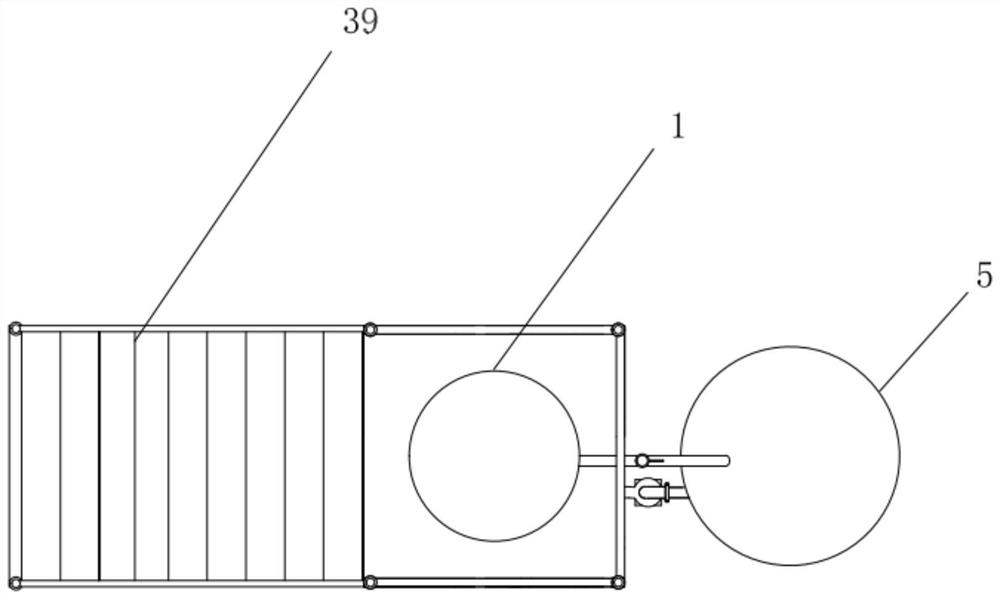

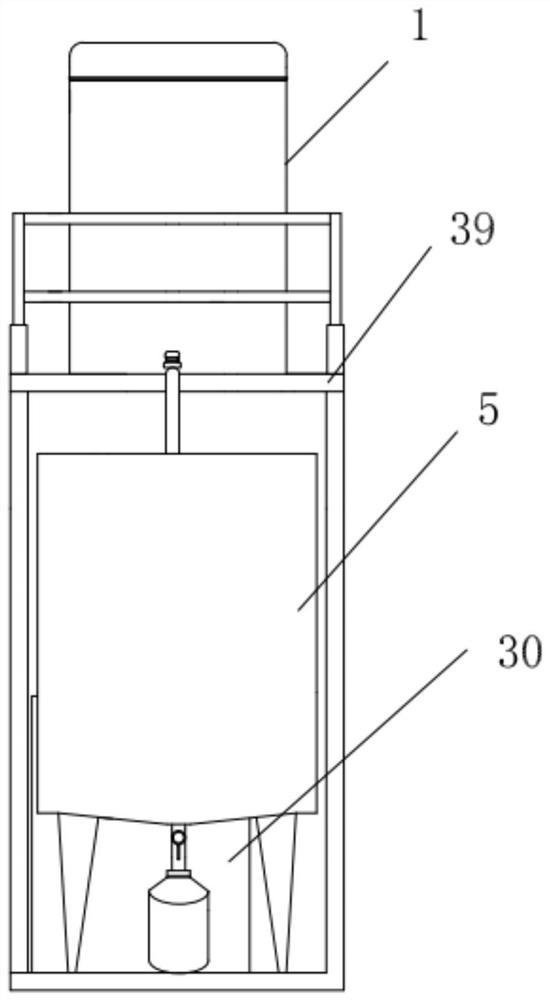

[0030] Such as Figure 1-Figure 16 Shown:

[0031] An energy-saving device for acidifying oil-water purification, comprising an escalator device 39, a storage tank device 1, a water washing tower device 5, and an oil-water separation tank device 30, and the storage tank device 1 includes a tank cover 2, a tank barrel 3 and an infusion tube 1 4. The bottom of the tank cover 2 is closed and connected to the upper part of the tank 3, which is characterized in that: the bottom of the tank 3 is connected with the infusion pipe 4, and the water washing tower device 5 includes a water washing tower 6, a stirring device 7, a filter 8 and a collection Bucket 9, the bottom of the transfusion tube-4 is inserted into the inside of the water washing tower 6, and the inside of the water washing tower 6 is provided with a stirring device 7, and the described stirring device 7 is provided with a separator 10, and the described transfusion tube-4 is placed in the separator 10, the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com