Side swing mechanism and method for flexible glass production

A side-swinging, flexible glass technology, used in glass production, conveyor objects, furnaces, etc., can solve problems such as crisis deterioration, unstable short rollers' holding force on glass, and poor adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

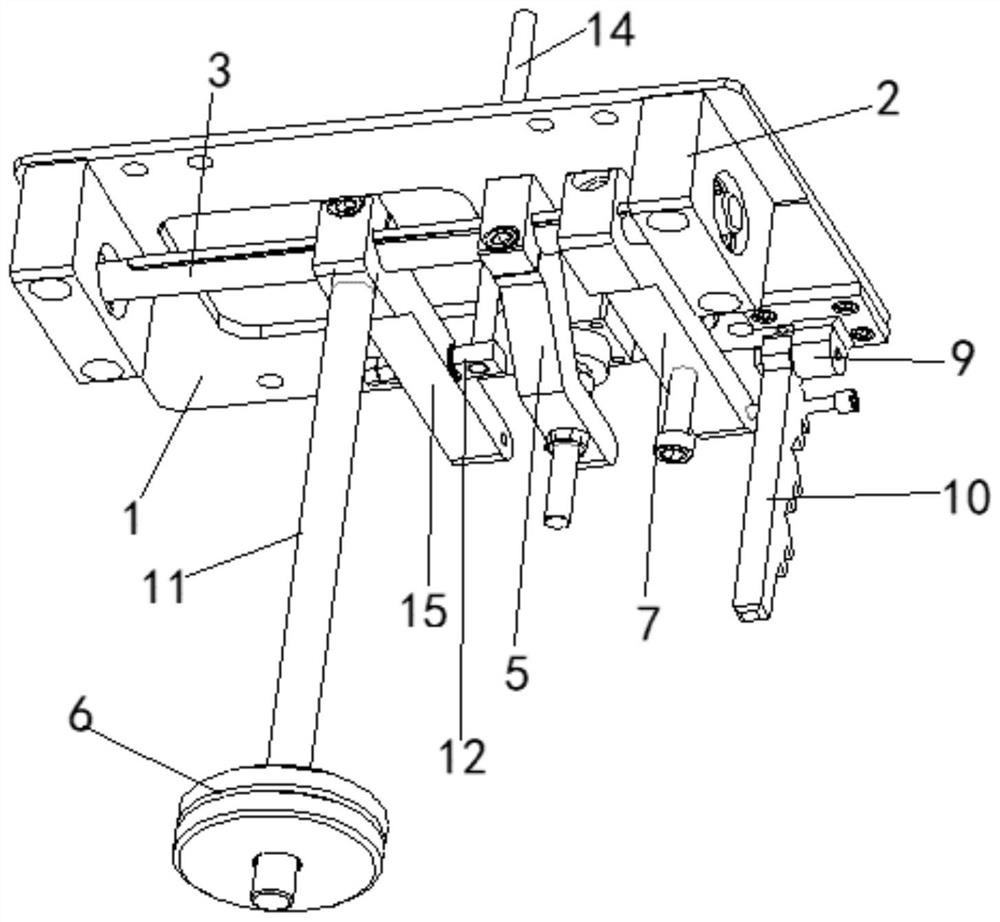

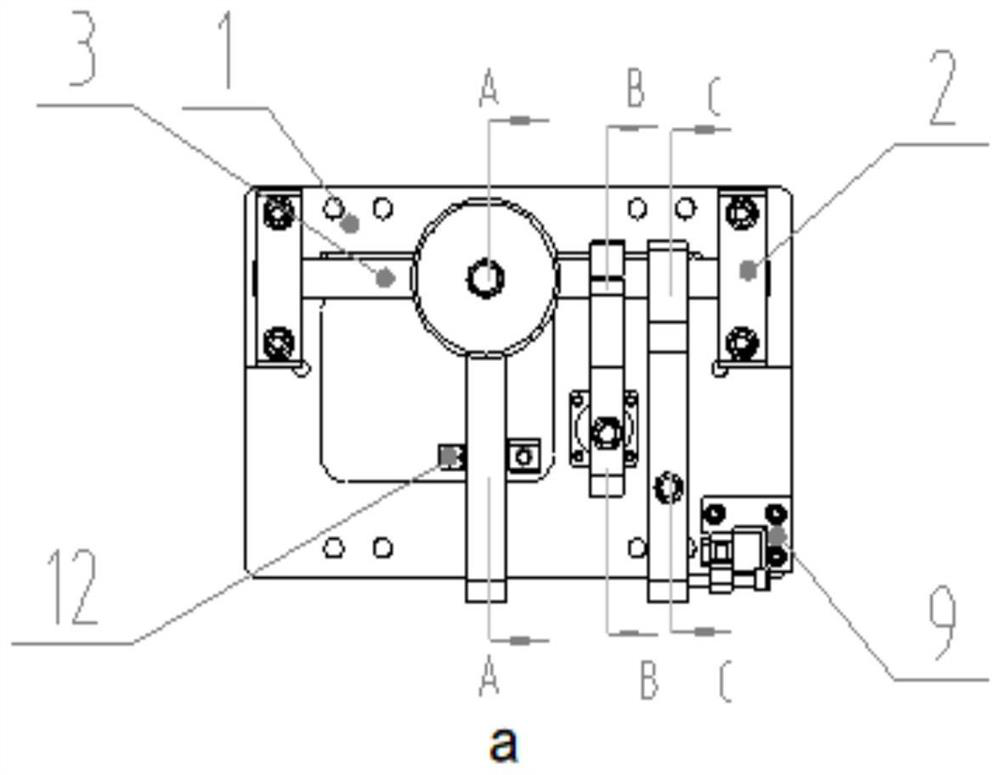

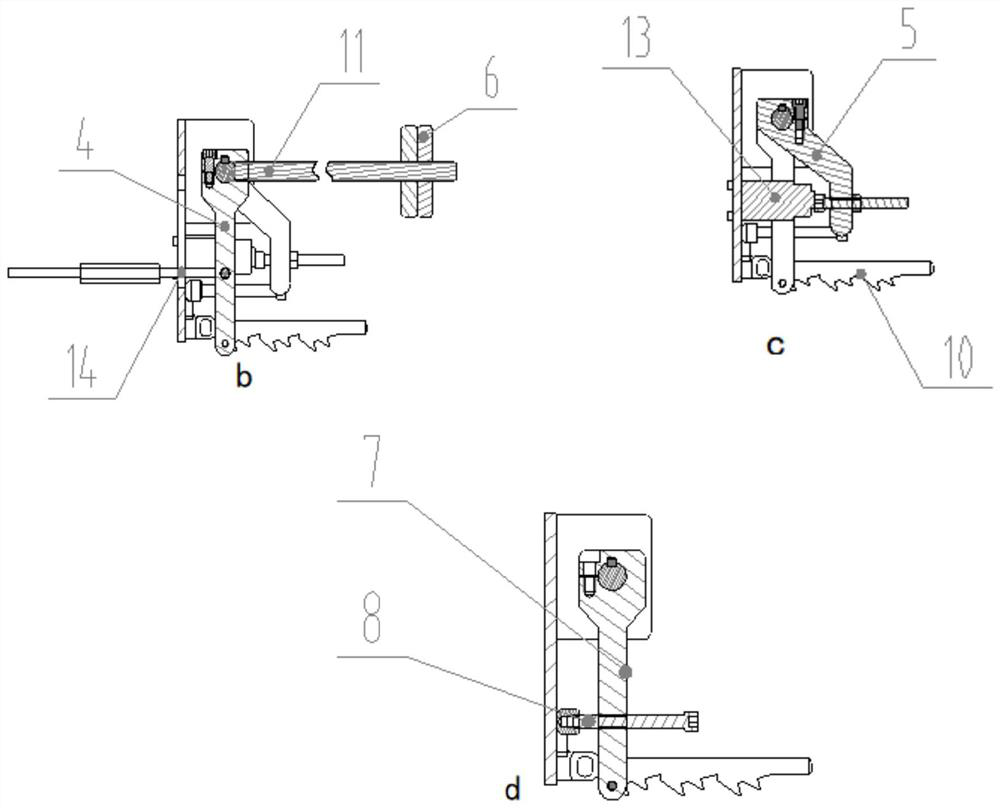

[0031] like figure 1 As shown, the present invention provides a side swing mechanism for flexible glass production. In the flexible glass production process, the short rollers for holding the glass are used in pairs. Correspondingly, the present invention controls the opening and closing of the short rollers. The side swing mechanisms are also used in pairs, and the pair of two side swing mechanisms are arranged opposite to the two sides of the glass clamped by the short rollers;

[0032] The side swing mechanism specifically includes: a side hanging plate 1 with a window on it, a counterweight link assembly 4 fixed on the end face of the side hanging plate 1 by a rotating fixing device, an emergency release lever 5 and a limit assembly, and the rotating fixing device includes The bearing seat 2 and the bracket shaft 3, the counterweight connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com