Multifunctional cradle roll type roller series automatic submerged arc welding machine

A submerged arc welding machine and multi-functional technology, applied in the direction of arc welding equipment, electrode characteristics, welding equipment, etc., can solve the problems of shortened service life, easy cracking of weld seam, high labor intensity, etc., to eliminate errors and facilitate clamping Workpiece, the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

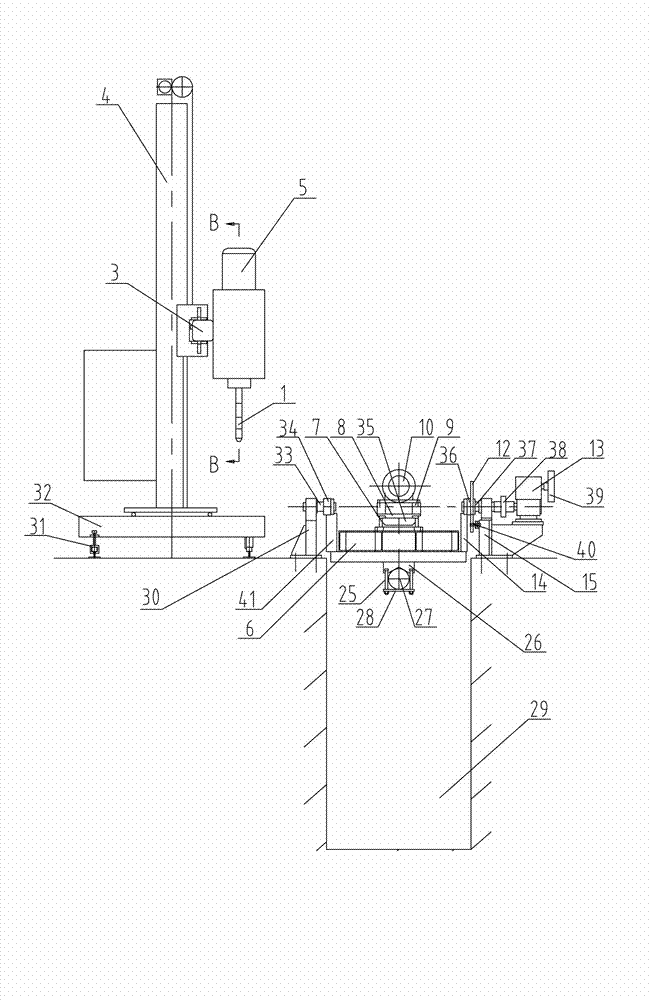

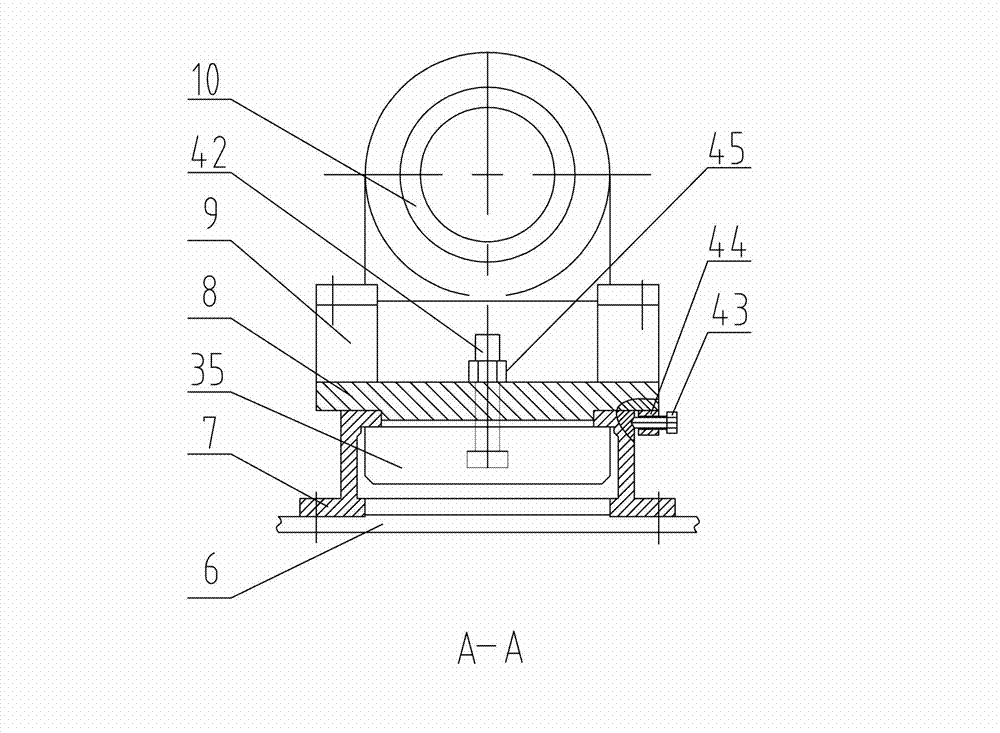

[0029] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

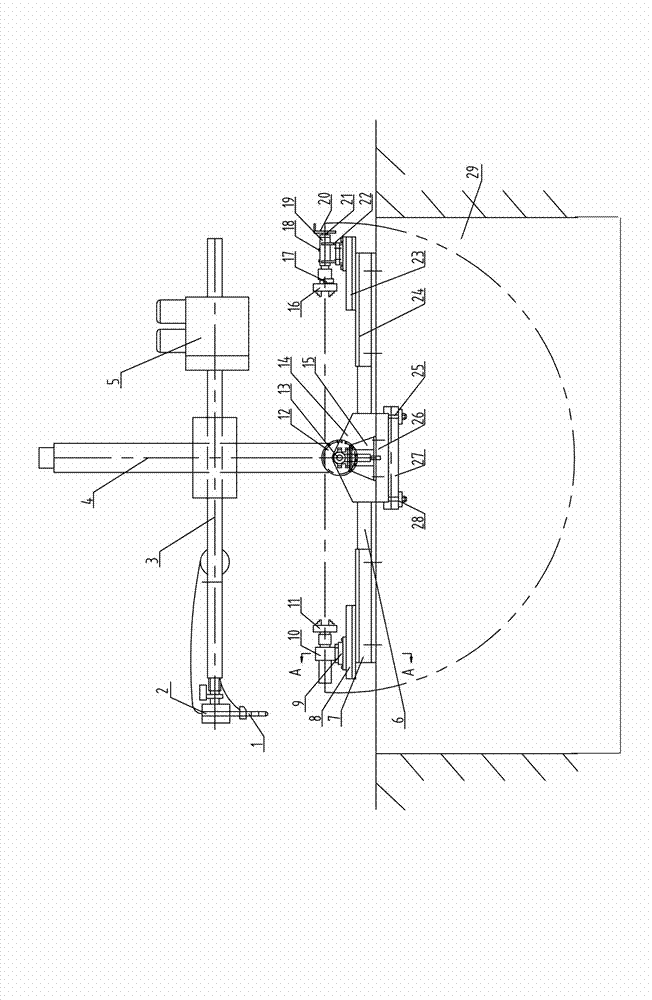

[0030] Such as figure 1 , 2 As shown, the multifunctional pendulum-type roller series automatic submerged arc welding machine of the present invention includes an orbital automatic submerged arc welding machine. This orbital automatic submerged arc welding machine consists of a welding machine track 31, and a straight line The welding machine trolley 32 of walking, the welding machine pillar 4 of circular movement on this welding machine trolley 32, the telescopic cross arm 3 that slides up and down connected with this welding machine pillar 4, the flux that is located at this telescopic cross arm 3 one ends gives The feeding device 5 and the welding torch 1 and the welding wire feeding device 2 arranged at the other end of the telescopic cross arm 3, and the electric control device with a console connected to the welding wire feeding dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com